Method of taking glass substrate

A technology for glass substrates and the outermost layer, which is applied in the field of glass substrate removal, can solve the problems of long takt time, falling glass substrates, and more time, and achieves the effect of reliable peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, one embodiment of the method for taking out a glass substrate according to the present invention will be described in detail with reference to the drawings.

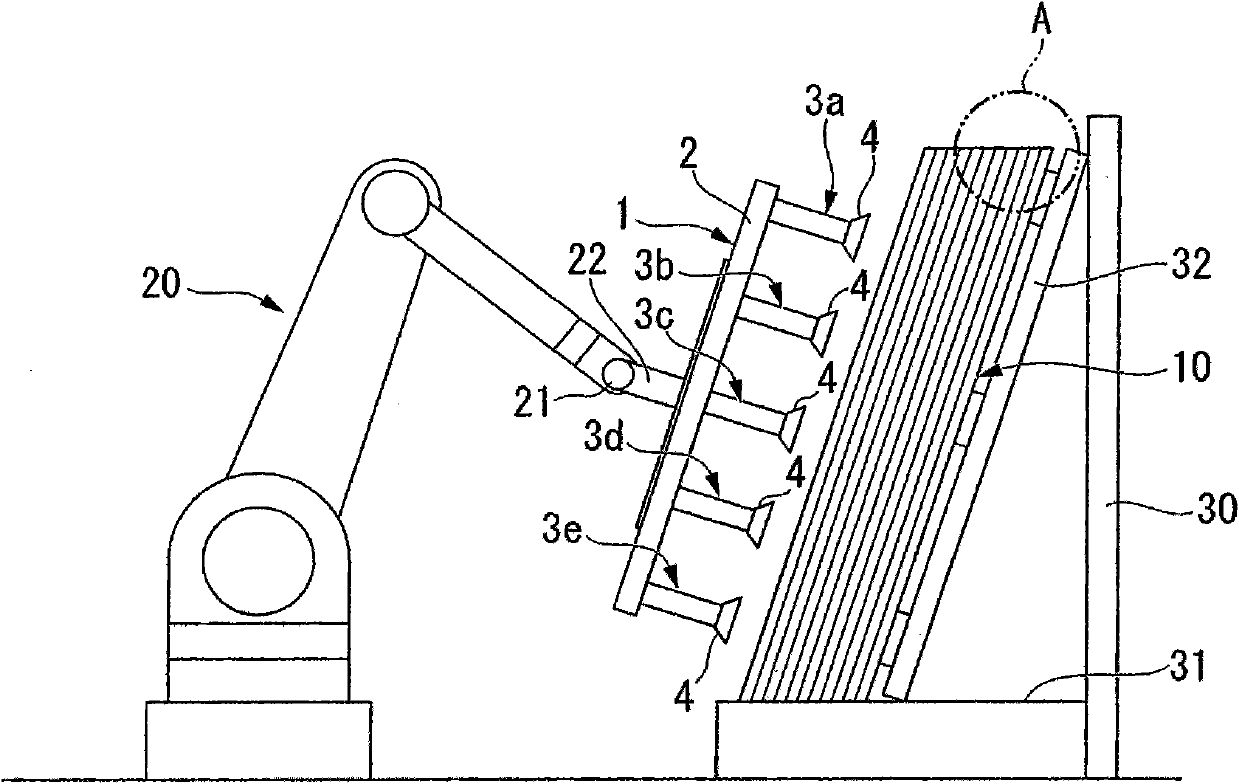

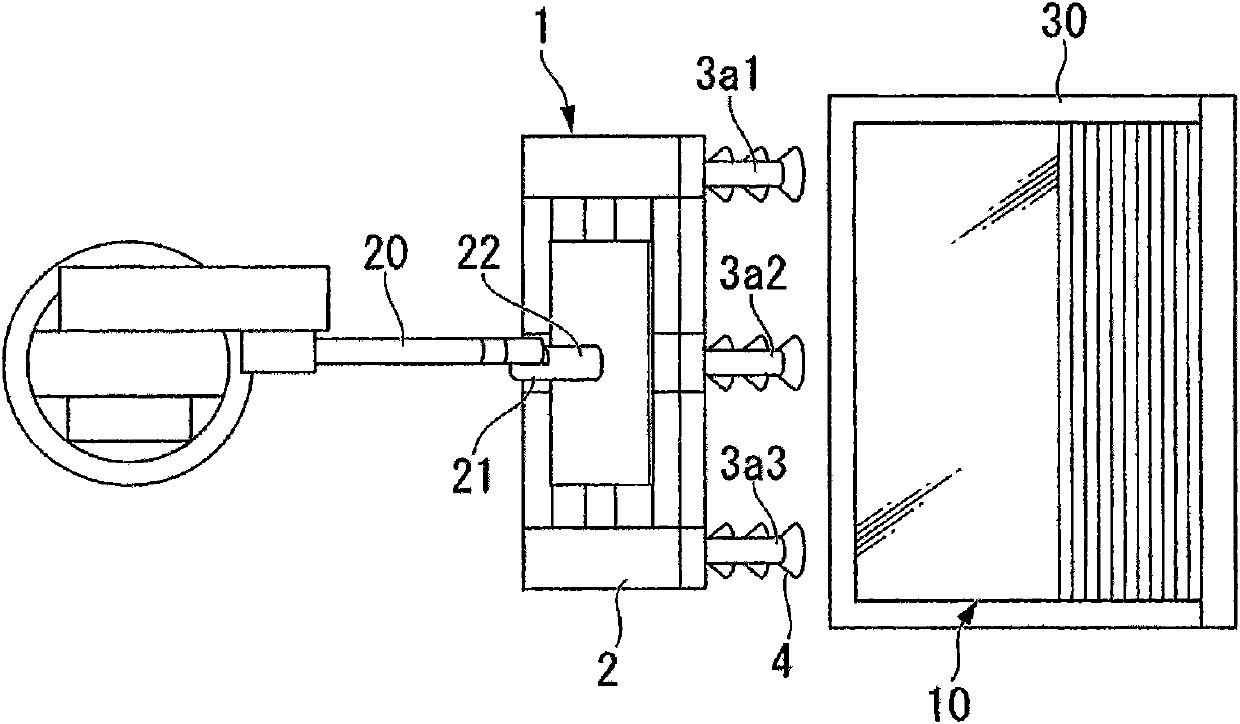

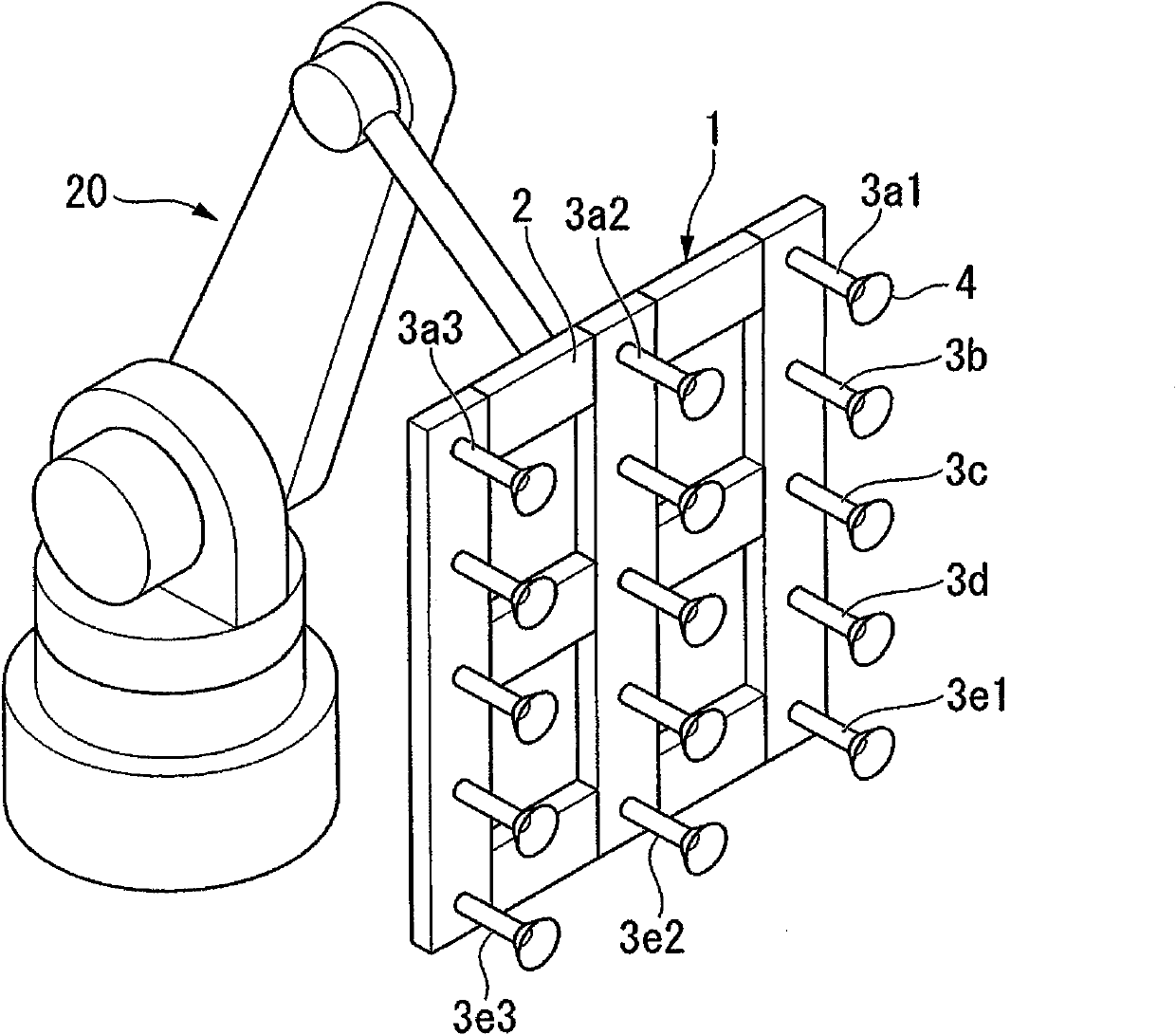

[0036] figure 1 It is a schematic side view showing the glass substrate take-out system used in this embodiment. figure 2 yes figure 1 top view. image 3 It is a perspective view of the glass substrate holding apparatus 1 attached to the front-end|tip part of the arm of the robot 20 used for a glass substrate extraction system. Figure 4 yes means figure 1 A partially enlarged view of the glass substrate assembly 10 in part A of FIG.

[0037] The glass substrate take-out system used in this embodiment includes: a bracket 30 that leans against and places the glass substrate assembly 10 obliquely; 1. A robot 20 supporting and freely moving the glass substrate holding device 1 .

[0038] The glass substrate take-out system of the present embodiment takes out the glass substrates 11 one by one f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com