Method for preparing tobacco flavour

A technology for tobacco flavor and tobacco, which is applied in the preparation of tobacco flavor and the field of tobacco flavor, and achieves the effects of high conversion rate and yield, low energy consumption, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

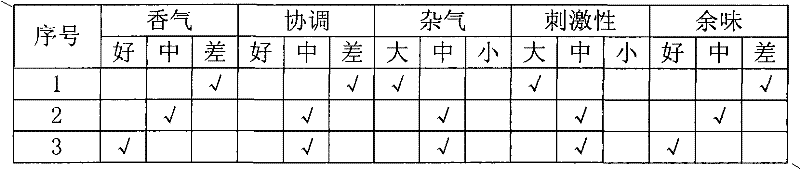

Embodiment 1

[0036] A kind of flavoring for tobacco is prepared, and the steps are as follows:

[0037] Accurately measure 9.9 g of diammonium hydrogen phosphate, dissolve it in distilled water to prepare an aqueous solution with a mass concentration of 9%, take 100 g of the solution, and adjust its pH value to 7.0-8.0 with sodium hydroxide.

[0038] To the resulting solution was added 13.2 g of 3-hydroxy-2-butanone and mixed well by stirring.

[0039] The uniformly mixed reaction solution was transferred to the reaction kettle, the heating device was turned on and the temperature was raised to 70° C., and the reaction was carried out under normal pressure for 12 hours, and then the temperature was lowered to room temperature, and the reaction was completed.

[0040] Dilute the reaction solution 5 times with distilled water, extract 3 times with dichloromethane, 300 mL each time, combine the organic phases, remove water with sodium sulfate, and then concentrate under reduced pressure. , a...

Embodiment 2

[0042] A kind of flavoring for tobacco is prepared, and the steps are as follows:

[0043] Measure 16.9 g of ammonium citrate, dissolve it in distilled water to prepare an ammonium citrate aqueous solution with a mass concentration of 14%, take 100 g of the solution, and adjust its pH value to 7.0-8.0 with sodium hydroxide.

[0044] To the resulting solution was added 13.2 g of 3-hydroxy-2-butanone, and the reaction solution was well mixed by stirring.

[0045] The uniformly mixed reaction solution was transferred to the reaction kettle, the heating device was turned on and the temperature was raised to 70° C., and the reaction was carried out under normal pressure for 12 hours, and then the temperature was lowered to room temperature, and the reaction was completed.

[0046] The resulting reaction solution was diluted 5 times with distilled water, extracted 3 times with dichloromethane, 300 mL each time, and the organic phase was combined to remove water with sodium sulfate, ...

Embodiment 3

[0048] Prepare a flavor for tobacco, the steps are as follows:

[0049] Measure 5 g of diammonium hydrogen phosphate and 8 g of ammonium citrate respectively, dissolve them in distilled water to prepare an aqueous solution with a mass concentration of 14%, take 100 g of the solution, and adjust its pH value to about 8.0 with sodium hydroxide.

[0050] To the obtained solution was added 12.9 g of 3-hydroxy-2-butanone, and the reaction solution was well mixed by stirring.

[0051] The uniformly mixed reaction solution was transferred to the reaction kettle, the heating device was turned on and the temperature was raised to 70° C., and the reaction was carried out under normal pressure for 12 hours, and then cooled to room temperature, and the reaction was completed.

[0052] The resulting reaction solution was diluted 5 times with distilled water, and then extracted 3 times with dichloromethane, 300 mL each time. After combining the organic phases, the water was removed with sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com