Rubber powder for producing building adhesive through cold water fast dissolution

A technology of construction glue and cold water, applied in the direction of adhesives, adhesive types, polysaccharide adhesives, etc., can solve the problems of increasing labor force of workers, harming health, harmfulness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

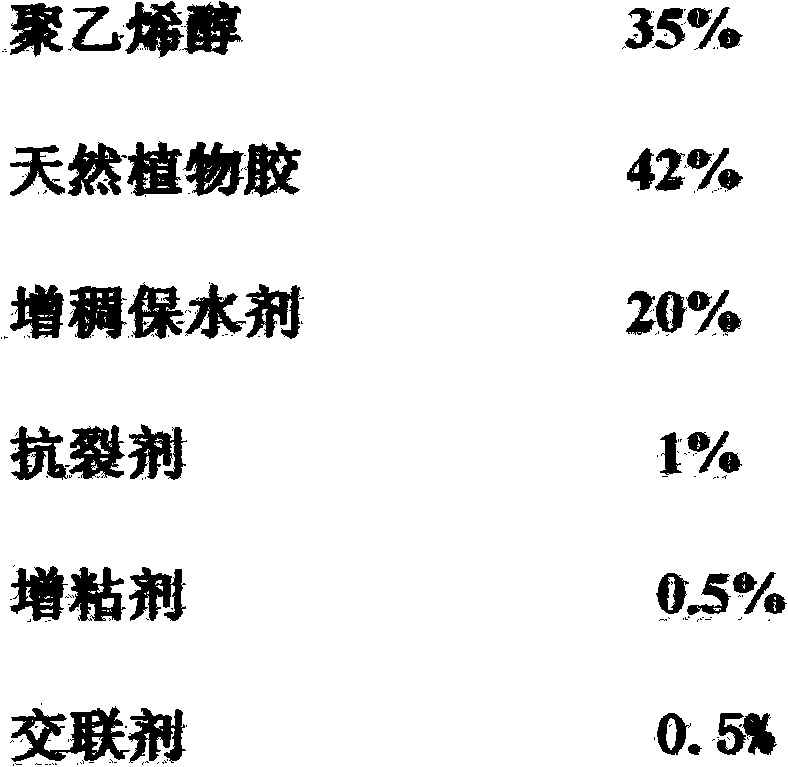

[0008] The mixing ratio of the rubber powder is

[0009] Polyvinyl alcohol 35% Natural vegetable glue 42% Thickening and water retention agent 20% Anti-cracking agent 1%

[0010] Tackifier 0.5% Crosslinker 0.5%

[0011] The production process is to put several raw materials into the closed mixer and mix them, and mix them evenly after half an hour. After mixing evenly, the product can be divided into bags, which can be 25 kg per pack or 1 kg per pack. To use this rubber powder to produce construction glue, first put water in the bucket, start the electric mixing equipment, stir while adding, after stirring, let it stand for 10-20 minutes to allow the glue to fully react and then use it. This rubber powder is a high-viscosity rubber powder. If there is some agglomeration due to improper operation, stir it after a few hours until it is completely dissolved and then use it.

[0012] The specific ratio of using the rubber powder to produce glue is to adjust 50 to 60 kilograms o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com