Spindle tape tension device of ring spinning frame

A spindle tape and tension technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problem of poor workmanship of support arms and adjustment frames, heavy hammer weight, and increased power consumption of the whole machine and other problems, to achieve the effect of changing the tension quickly and easily, the tension of the spindle tape is stable, and the mechanism is simple and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

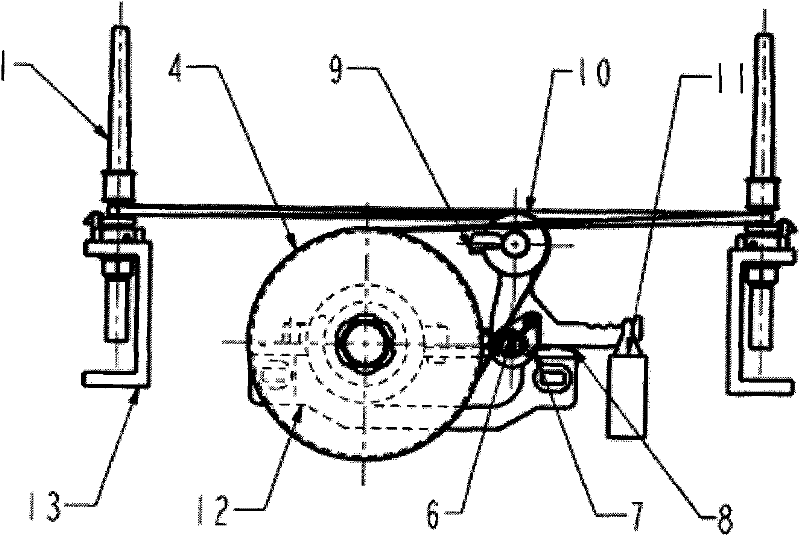

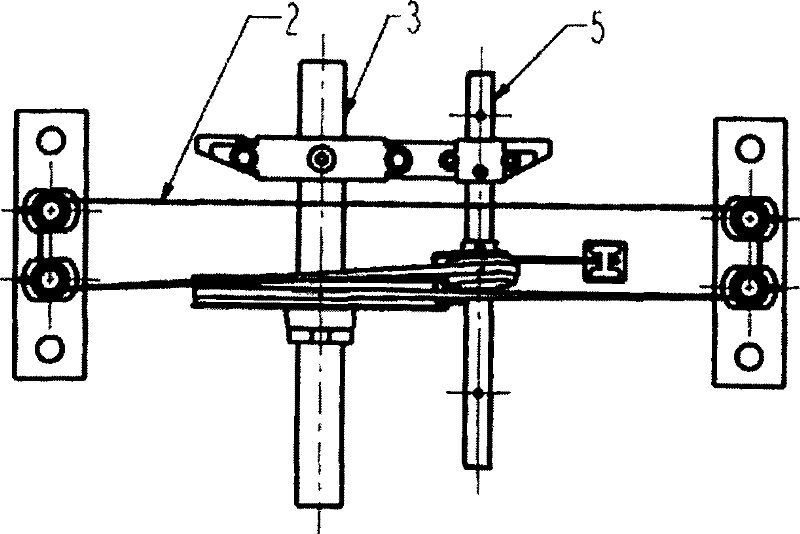

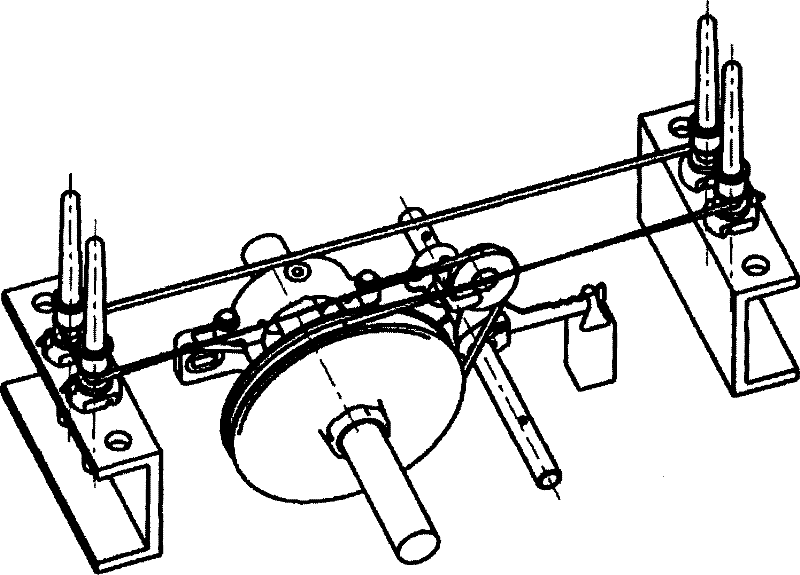

[0013] A spindle belt tensioning device for a ring spinning frame includes a spindle 1, a spindle belt 2, a main shaft 3, a rolling plate 4, a tension wheel shaft 5, a positioning pin 6, a support ring 7, a bracket 8, a tension wheel frame 9, and a spindle belt tension wheel 10 , heavy hammer 11, main shaft bearing seat 12 and dragon bar 13; main shaft 3 and tension wheel shaft 5 are set on main shaft bearing seat 12, rolling disc 4 is set on main shaft 3, positioning pin 6 is set on tension wheel shaft 5, supporting ring 7 Set on the tension wheel shaft 5 and positioning pin 6, the bracket 8 is set on the support ring 7, the weight 11 is set on one end of the bracket 8, the tension wheel frame 9 and the spindle belt tension wheel 10 are set on the other end of the bracket 8, the spindle 1 is arranged on the dragon tendon 13, and the spindle tape 2 is arranged on the rolling plate 4, the spindle tape tension wheel 10 and the four spindles 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com