Frictional false twisting device

A device, false twisting technology, applied in the direction of rotational vibration suppression, textile and paper making, etc., to achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

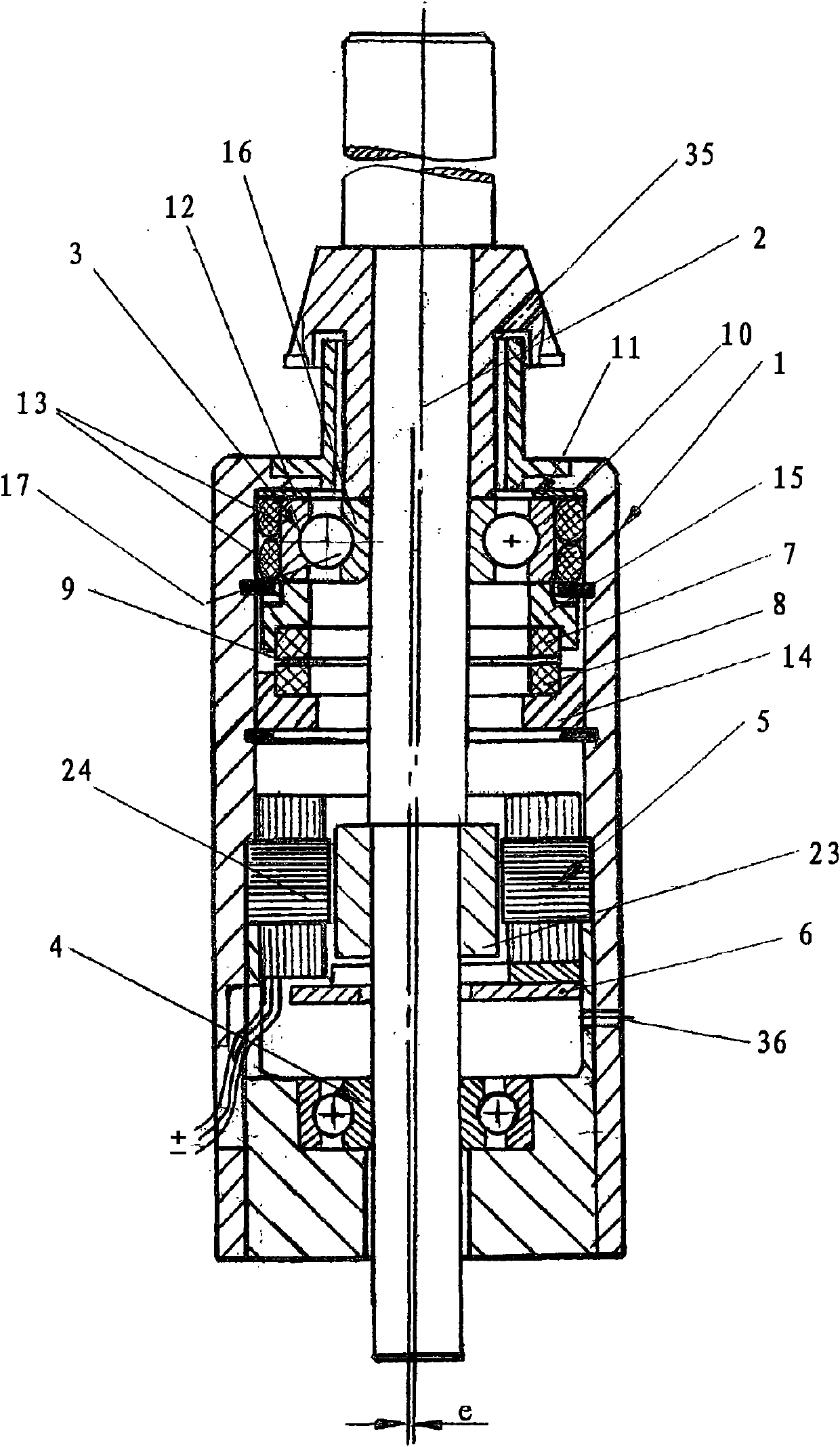

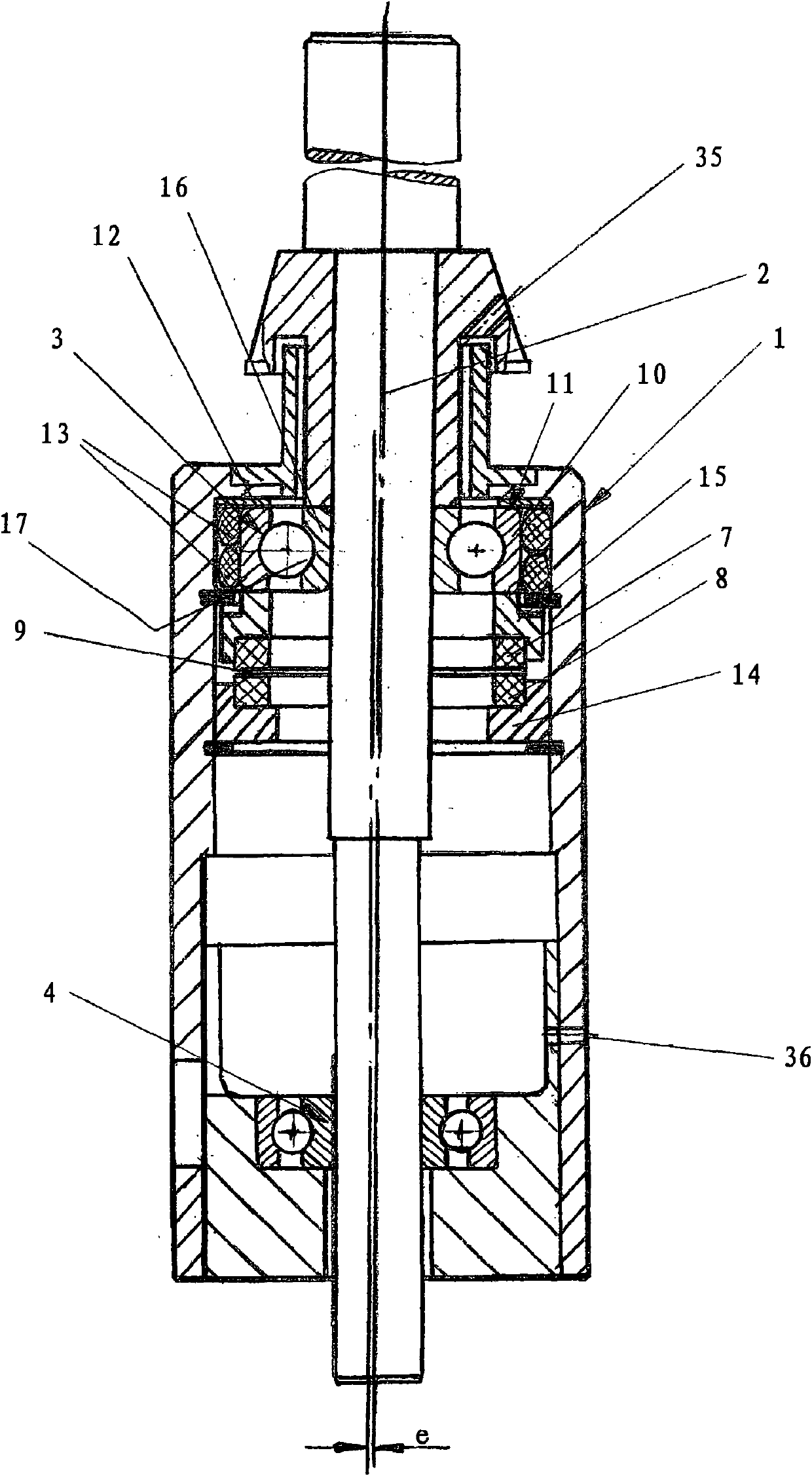

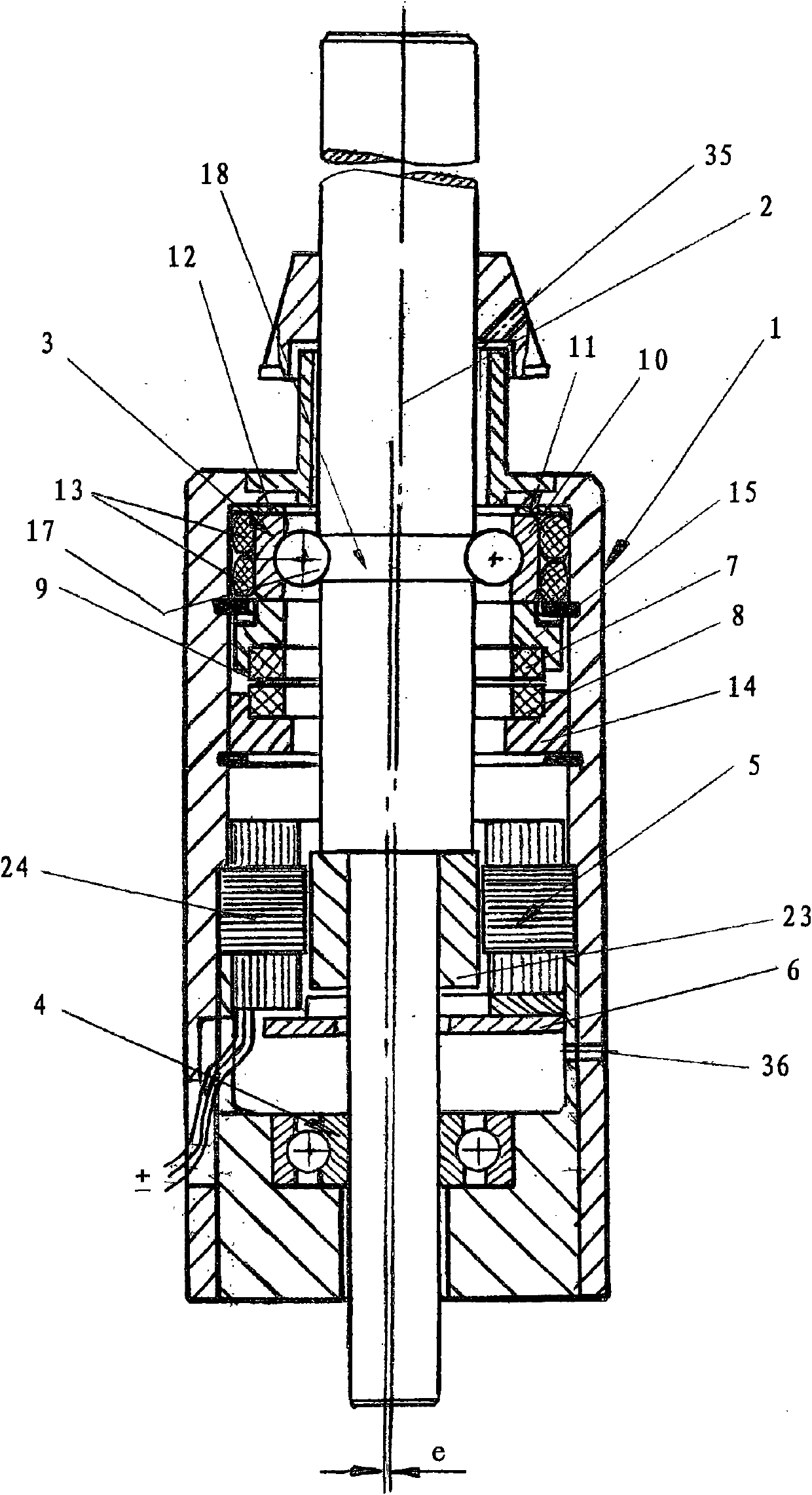

[0019] figure 1 and figure 2 Two embodiments of friction spindles are shown, in which figure 1 and figure 2 The only difference is that figure 1 equipped with an electric motor, and figure 2 There is no electric motor. also, figure 1 and figure 2 It is also shown that the spindle shaft 2 has an eccentricity "e" relative to the outer diameter of the spindle sleeve 1 . In the case of an electric motor integrated between the upper rolling bearing 3 and the lower rolling bearing 4 , the controller of the electric motor is integrated in the electric motor itself.

[0020] also, figure 1 and figure 2 The upper rolling bearing 3 which surrounds the spindle shaft is shown with a so-called damper. The damper is integrated in the figure 1 and figure 2 In the friction equipment, in order to avoid the resonance of the critical speed in the working range of 6000 to 20000 rpm. The shifting of the resonance at a critical speed of 6000 rpm is achieved in that two mutually r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com