Embedded combined high manganese steel frog

A high manganese steel, embedded technology, applied in the direction of switch, road, track, etc., can solve the problems of unable to meet the requirements of inter-interval seamless lines, fast wear of the top surface of wing rail, and unable to meet the needs of users, etc., to achieve enhanced Wear resistance, improved service life, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

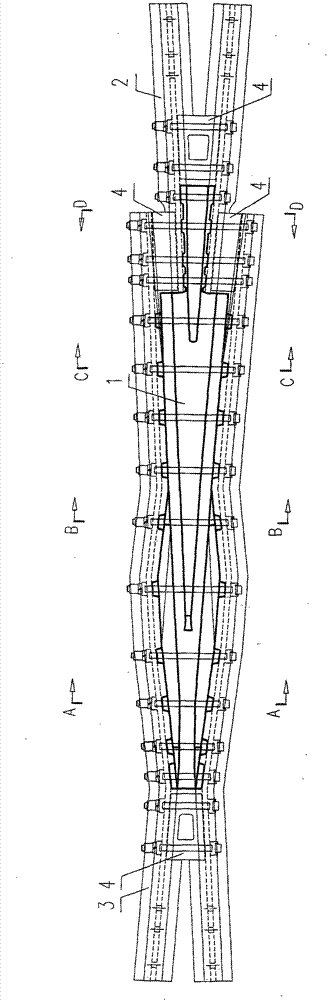

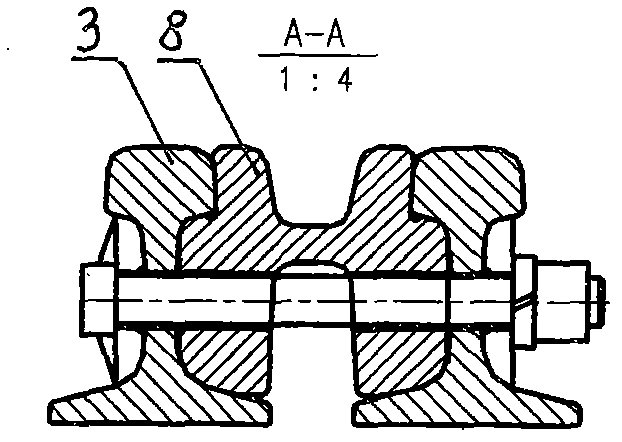

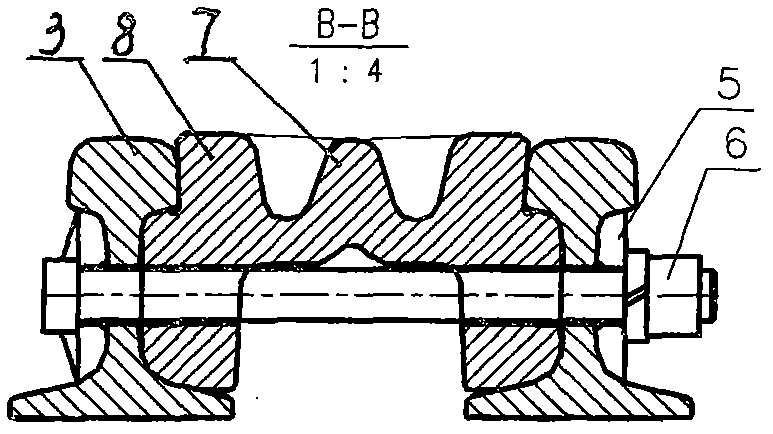

[0023] Attached below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10 describe an embodiment of the present invention in detail.

[0024] An embedded combined high manganese steel frog has a fork center 1 , a heel rail 2 and a wing rail 3 . The fork core 1 is integrally cast with high manganese steel, and the fork core 1 is embedded between two symmetrically arranged wing rails 3 . Flanges 9 are distributed symmetrically and evenly on both sides of the fork center 1. On the one hand, bolt connection holes 10 are formed at the flanges 9; , the bolt connection pair 6 passes through the bolt connection hole 10 through the rail washer 5 to connect and fix the fork 1 and the two wing rails 3 together. The two fork rails 2 are symmetrically arranged on both sides of the tail of the fork center 1, and are located between the two wing rails 3. The bolt connection pair 6 passes through the bolt connection hole 10 and connects the two wing rails through the rail washer 5 and the spacer iron 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com