A kind of carbide-containing austempering ductile iron hammer head and its preparation method and application

A technology of austempering and ductile iron, applied in grain processing and other directions, can solve the problems of high price and unsuitable cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

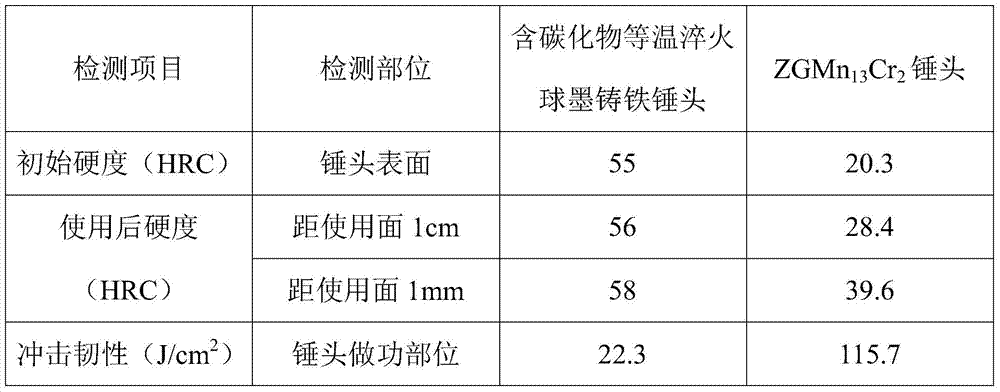

Examples

Embodiment 1

[0030] A carbide-containing austempering ductile iron hammer head proposed by the present invention, its components include: carbon: 3.4%, silicon: 3.0%, manganese: 0.2%, chromium: 0.6%, molybdenum: 0.2%, copper : 0.6%, nickel: 0.3%, phosphorus: ≤0.05%, sulfur: ≤0.03%, and the rest is iron.

Embodiment 2

[0032] A carbide-containing austempering ductile iron hammer head proposed by the present invention, its components include by weight percentage: carbon: 3.8%, silicon: 2.2%, manganese: 0.5%, chromium: 0.4%, molybdenum: 0.3%, copper : 0.4%, nickel: 0.4%, phosphorus: ≤0.05%, sulfur: ≤0.03%, and the rest is iron.

Embodiment 3

[0034] A carbide-containing austempering ductile iron hammer head proposed by the present invention, its components include by weight percentage: carbon: 3.6%, silicon: 2.5%, manganese: 0.45%, chromium: 0.5%, molybdenum: 0.23%, copper : 0.44%, nickel: 0.32%, phosphorus: ≤0.05%, sulfur: ≤0.03%, and the rest is iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com