Manganese-steel-based multiphase particle reinforced cermet surface composite material, casting and manufacturing method thereof

A surface composite material and particle-reinforced technology, which is applied in the direction of metal processing equipment, transportation and packaging, and improvement of process efficiency, to achieve high toughness, increased density, and improved support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

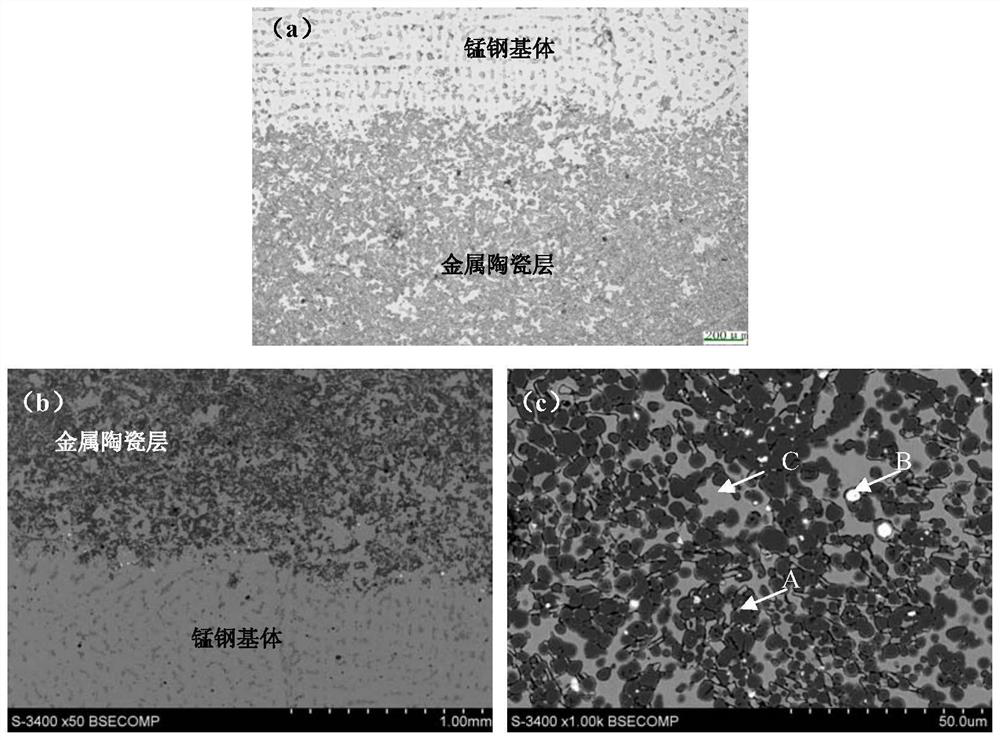

Embodiment 1

[0121] The invention provides a manganese-steel-based titanium carbide / tungsten carbide multiphase particle-reinforced cermet surface composite material, which is composed of a high-toughness austenitic manganese steel matrix material and a particle-reinforced cermet surface composite material, wherein the particle-reinforced cermet Surface composite materials are in-situ synthesis of TiC, WC, Al 2 O 3 TiC, WC, (Ti, W) and alloy carbides, borides and other complex particles reinforced manganese steel-based surface wear-resistant composite materials.

[0122] The further optimized technical solution of this embodiment is that the manganese steel-based titanium carbide / tungsten carbide composite particle reinforced cermet surface composite material contains titanium metal powder, metal tungsten powder, colloidal graphite powder, ferrochromium alloy powder, molybdenum metal powder in the main raw materials. The iron alloy powder, boron alloy powder and rare earth are characteri...

Embodiment 2

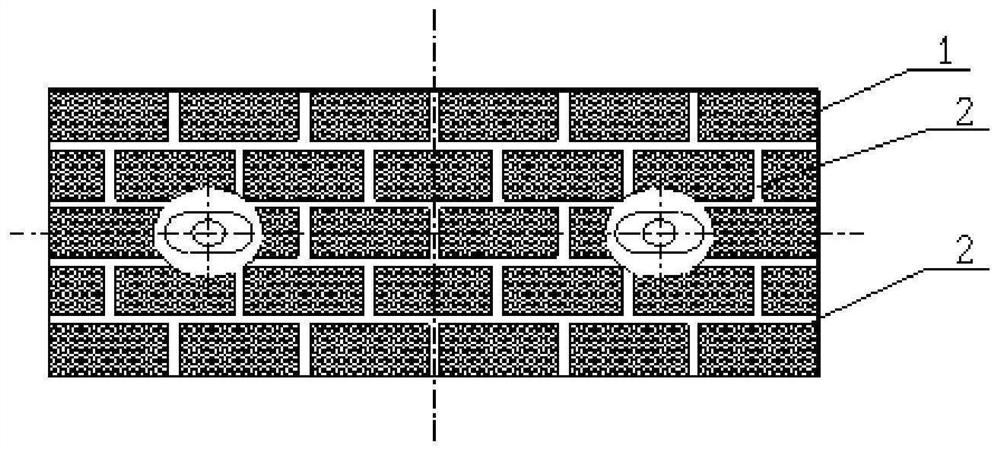

[0143]A manganese steel-based multiphase particle-reinforced cermet surface composite material, similar to Example 1, except that 1200g of titanium metal powder with a particle size of 30-45μm, 150g of tungsten metal powder of 18-23μm, 13- 18μm colloidal graphite powder 310g, 75μm high carbon ferrochromium powder 200g, 23μm 60 molybdenum iron alloy powder 50g, 75μm 20 low carbon boron iron alloy powder 40g and 100μm rare earth ferrosilicon alloy powder 50g, mixed in a V-type mixer 6h, then add about 400g of 2% sodium carboxymethylcellulose (CMC) aqueous solution, and stir in a mixer for 1.0h to make alloy powder. Add the evenly mixed alloy powder into the mold and press it into a prefabricated block with a pressing force of 10 MPa, dry it in a constant temperature blast drying oven for 4 hours at a temperature of 120 °C, and fix the dried prefabricated block with an organic adhesive. In the groove of the ball mill liner foam white mold model. Then, hang a magnesia powder coat...

Embodiment 3

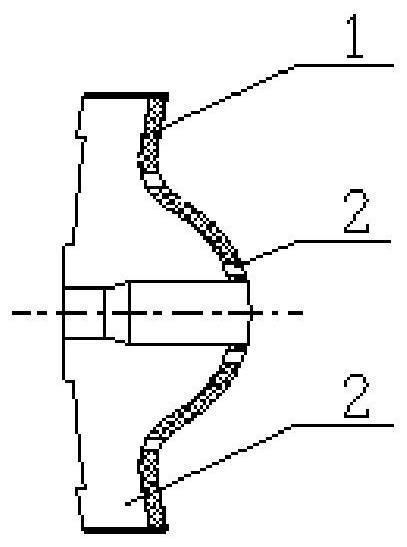

[0148] A manganese steel-based multiphase particle reinforced cermet surface composite material, similar to Example 1, except that 600g of titanium metal powder with a particle size of 20-45μm, 75g of 20-45μm metal tungsten powder, 13- 155g of 18μm colloidal graphite powder, 100g of 75μm high-carbon ferrochromium powder, 30g of 18μm 55-molybdenum-iron alloy powder, 20g of 20μm borax powder and 75μm rare earth silicon-magnesium alloy powder 20g, mixed in a V-type mixer for 2 hours, and then Add about 200 g of 3% sodium carboxymethyl cellulose (CMC) aqueous solution, and stir in a mixer for 1.0 h to make alloy powder. Add the evenly mixed alloy powder into the mold and press it into a prefabricated block with a pressing force of 6MPa, dry it in a constant temperature blast drying oven for 3 hours at a temperature of 80 °C, and fix the dried prefabricated block with an organic adhesive. Wear-resistant surface on a foam white mold model of a pile driver bucket tooth. Then, hang a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com