Method for constructing special shaped deepwater cofferdams on steep rocky riverbeds

A construction method and technology of cofferdam, applied in the direction of infrastructure engineering, construction, etc., to achieve the effect of high construction feasibility and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

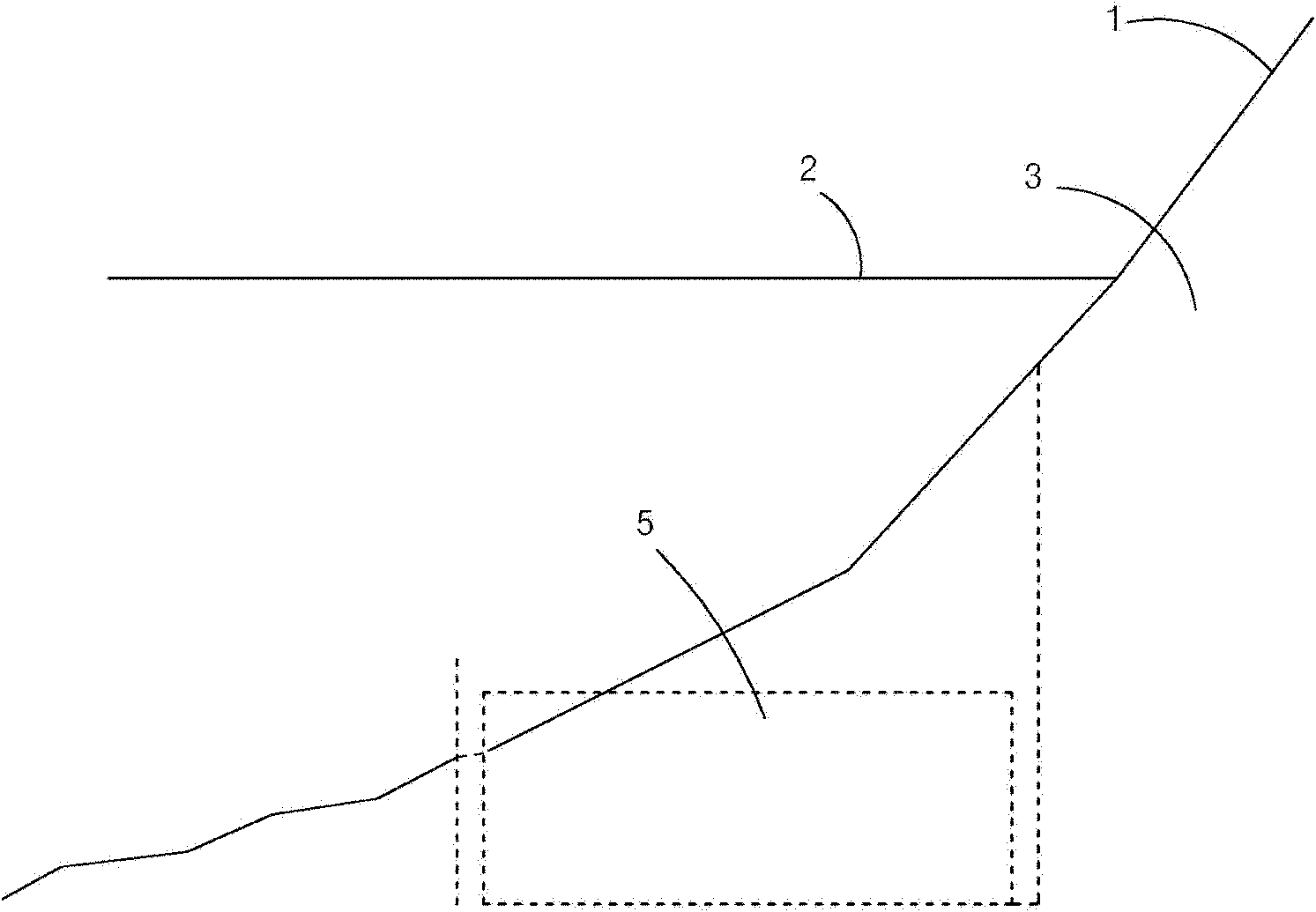

[0022] This example is in figure 1 The environment shown requires the construction of bridge foundations 5, figure 1 Among them, the riverbed below the water level 2 is a rocky riverbed, that is, the rock mass 3. The rock quality of the rock mass 3 is relatively hard, and the rock surface of the riverbed surface 1 has a relatively large slope, so it is not suitable for slotting or other methods to fix the enclosure. Weir wall6.

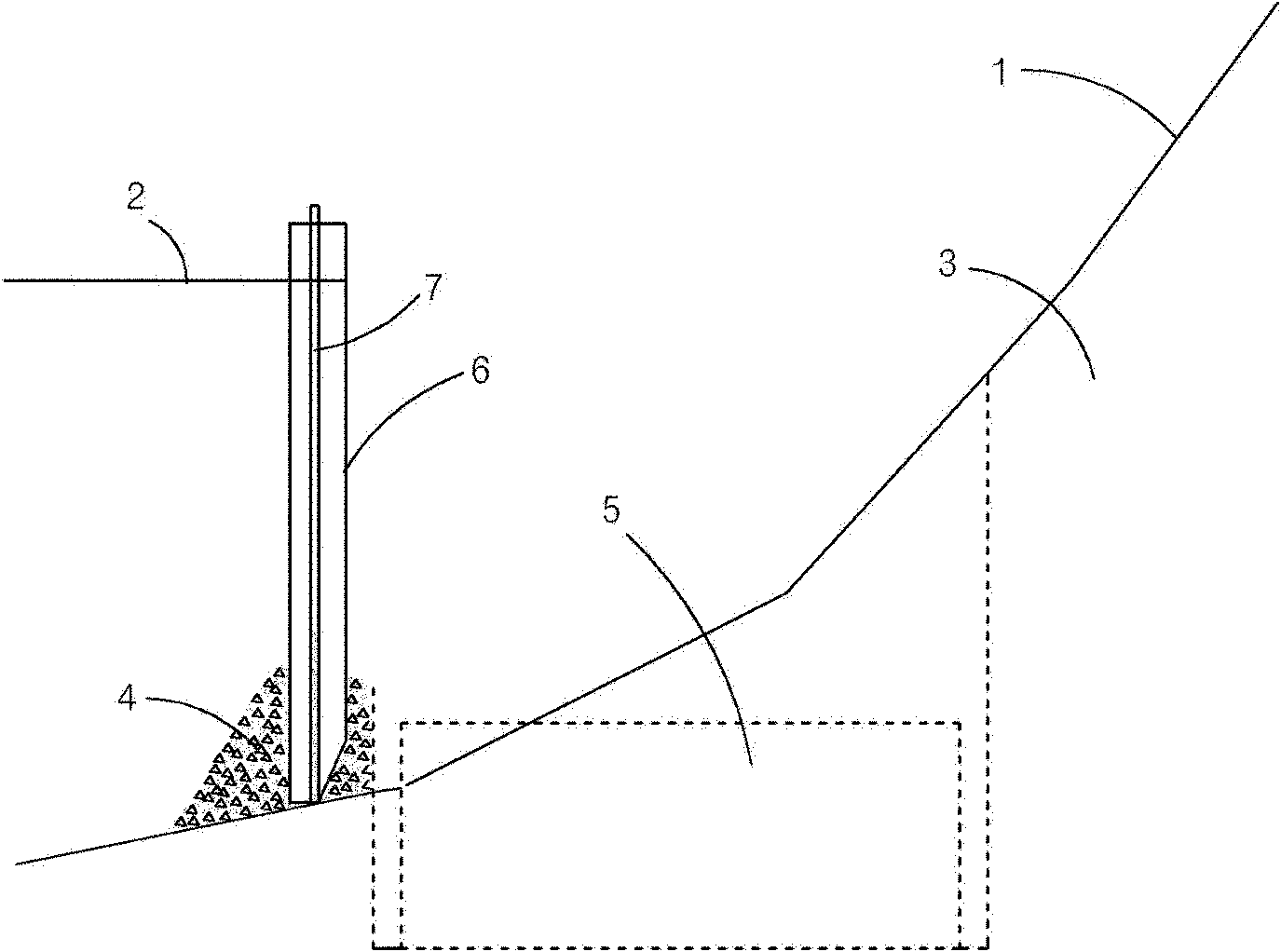

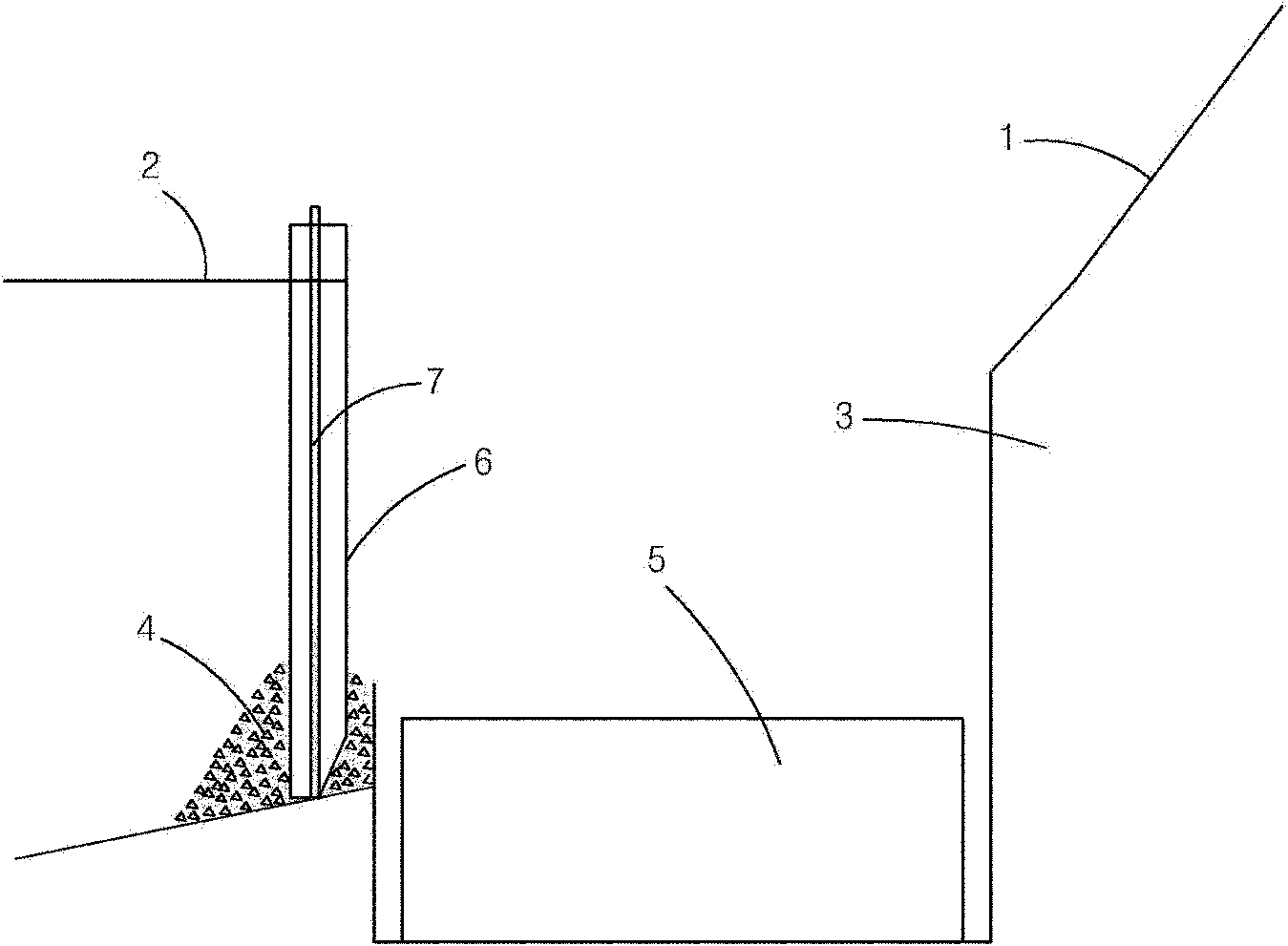

[0023] see figure 2 and image 3 , the cofferdam in the present embodiment is constructed according to the following steps:

[0024] 1. The prefabricated cofferdam wall 6 is provided with grouting pipes 7 vertically and vertically penetrating through the cofferdam wall 6, and the grouting pipes 7 are spaced and evenly arranged in the cofferdam wall 6;

[0025] 2. Sink the cofferdam wall 6 to the river bed, keep the top of the grouting pipe 7 exposed above the water level 2, and use the grouting pipe 7 to flush the river bed with jet water. The fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com