Suction fan impeller of mower

A technology for exhaust fans and lawn mowers, which is applied in the directions of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as affecting the mowing efficiency of combined lawn mowers and not being suitable for cutting weeds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

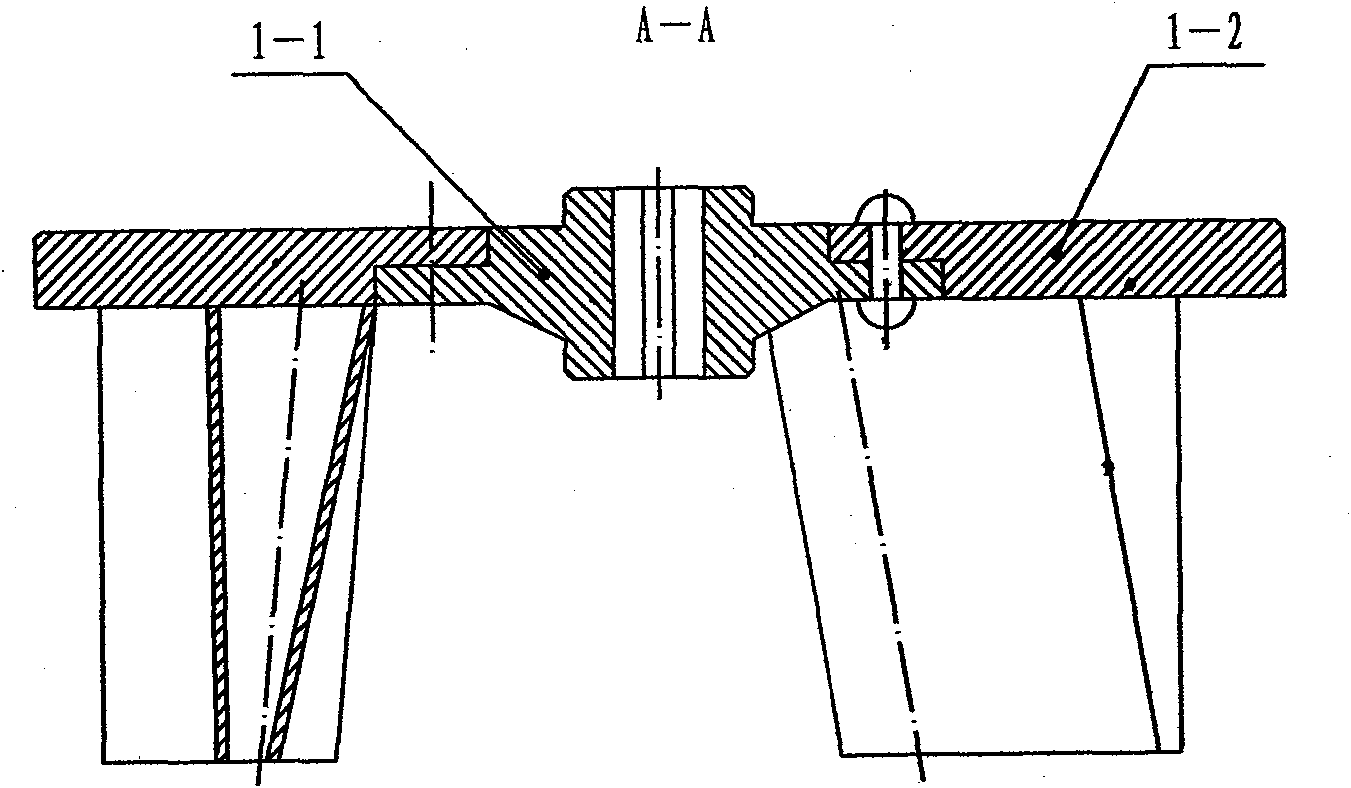

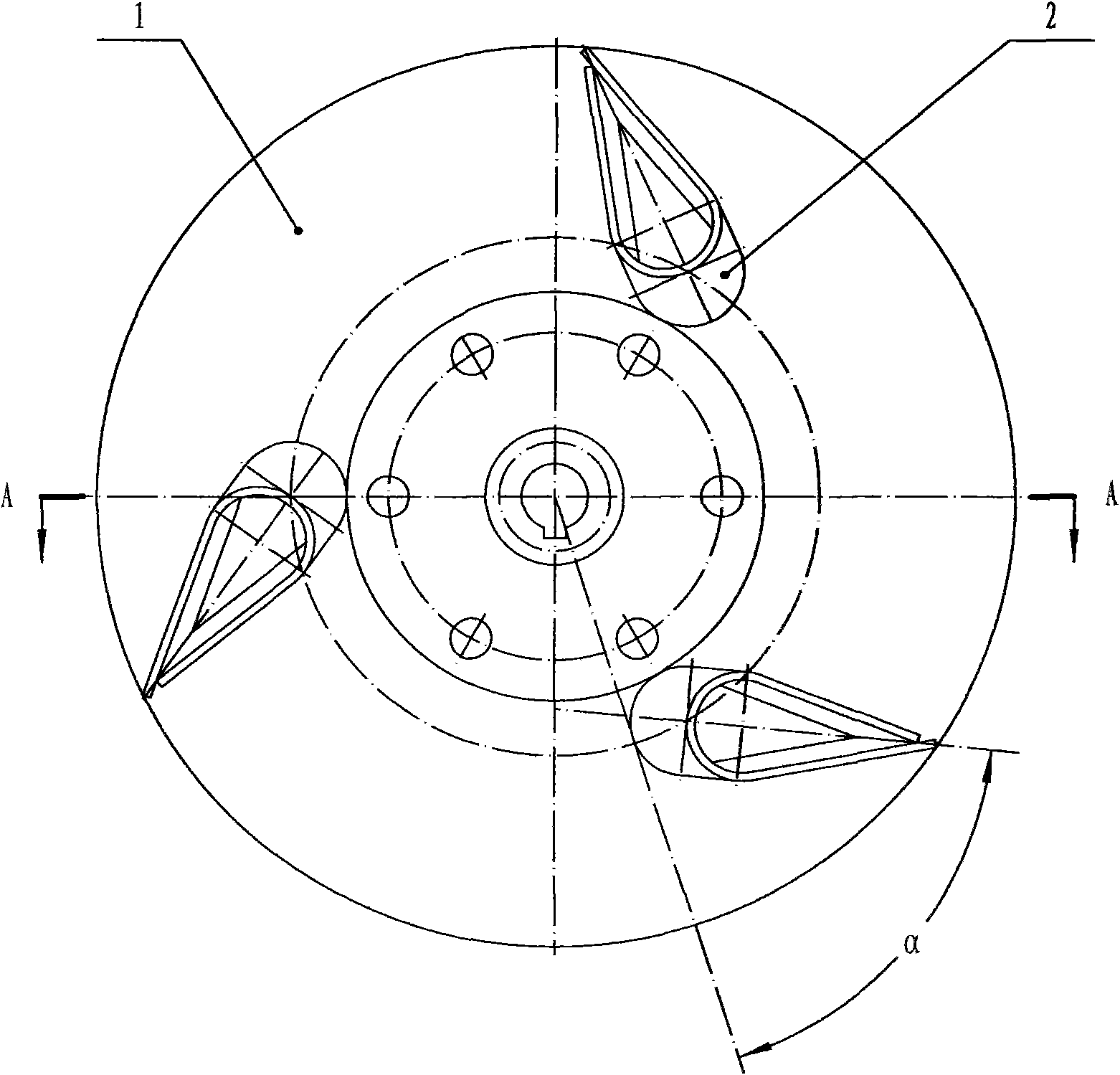

[0019] exist figure 1 , 2 Among them, the exhaust fan impeller of the lawn mower in this embodiment is composed of a disc 1 and a blade 2 connected.

[0020] The wheel disk 1 of this embodiment is composed of a hub 1-1 and a blade disk 1-2. The outer edge of the wheel hub 1-1 is connected with the blade disk 1-2 by rivets to form the wheel disk 1, and the wheel hub 1-1 and the blade disk 1-2 can also be fixedly connected by threaded fasteners. On the blade disk 1-2 of the wheel disk 1, three blades 2 are evenly distributed and welded, the inner end of the blade 2 overlaps the outer end of the hub 1-1, and the center line of the blade 2 is tangent to the inner end of the blade 2. The angle α between the diameters is 60°.

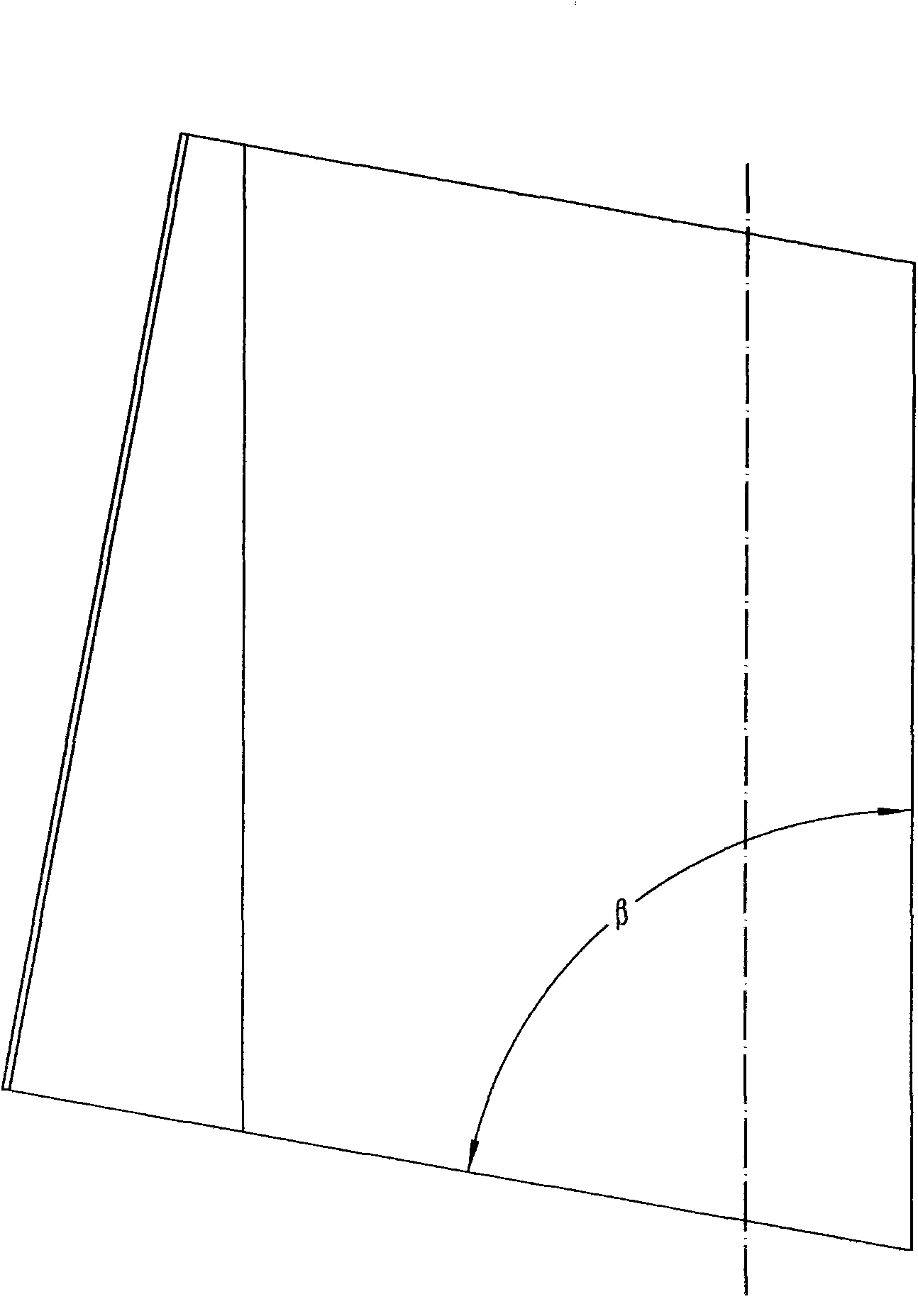

[0021] image 3 , 4 A schematic structural view of the blade 2 of this embodiment is given. exist image 3 , 4 Among them, the blade 2 of this embodiment is made by welding the outer end of the front side and the inner surface of the rear side after a...

Embodiment 2

[0023] In this embodiment, the number of welded blades 2 on the blade disk 1 - 2 of the wheel disk 1 and the included angle α between the center line of the blade 2 and the diameter tangent to the inner end are the same as those in Embodiment 1. The blade 2 of this embodiment is made by welding the outer end of the front side and the inner surface of the rear side after a piece of steel plate is crimped. The angle β is 50°. The rear side of blade 2 is trapezoidal, and the outside edge of trapezoid is perpendicular to base, and the plane where the upper base of trapezoid and the upper base of parallelogram is parallel to the plane where the lower base of trapezoid and the lower base of parallelogram are. The included angle γ between the anteromedial inner surface and the posterior inner inner surface of the blade 2 is 20°. The inner end of the blade 2 is a circular arc surface with a radius R of 15mm that is tangent to the front outer surface and the rear outer surface and is ...

Embodiment 3

[0025] In this embodiment, the number of welded blades 2 on the blade disk 1 - 2 of the wheel disk 1 and the included angle α between the center line of the blade 2 and the diameter tangent to the inner end are the same as those in Embodiment 1. The blade 2 of this embodiment is made by welding the outer end of the front side and the inner surface of the rear side after a piece of steel plate is crimped. The angle β is 80°. The rear side of blade 2 is trapezoidal, and the outside edge of trapezoid is perpendicular to base, and the plane where the upper base of trapezoid and the upper base of parallelogram is parallel to the plane where the lower base of trapezoid and the lower base of parallelogram are. The angle γ between the front inner surface and the rear inner surface of the blade 2 is 45°. The inner end of the blade 2 is a circular arc surface with a radius R of 30mm that is tangent to the front outer surface and the rear outer surface and is connected as a whole. Othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com