Refrigerator

A technology for refrigerators and heat-insulated boxes, which is applied in the field of blower refrigerators, which can solve the problems of reducing the rigidity of side panels, increasing the space occupied by refrigerators, and deteriorating appearance, so as to improve heat dissipation performance and realize the effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

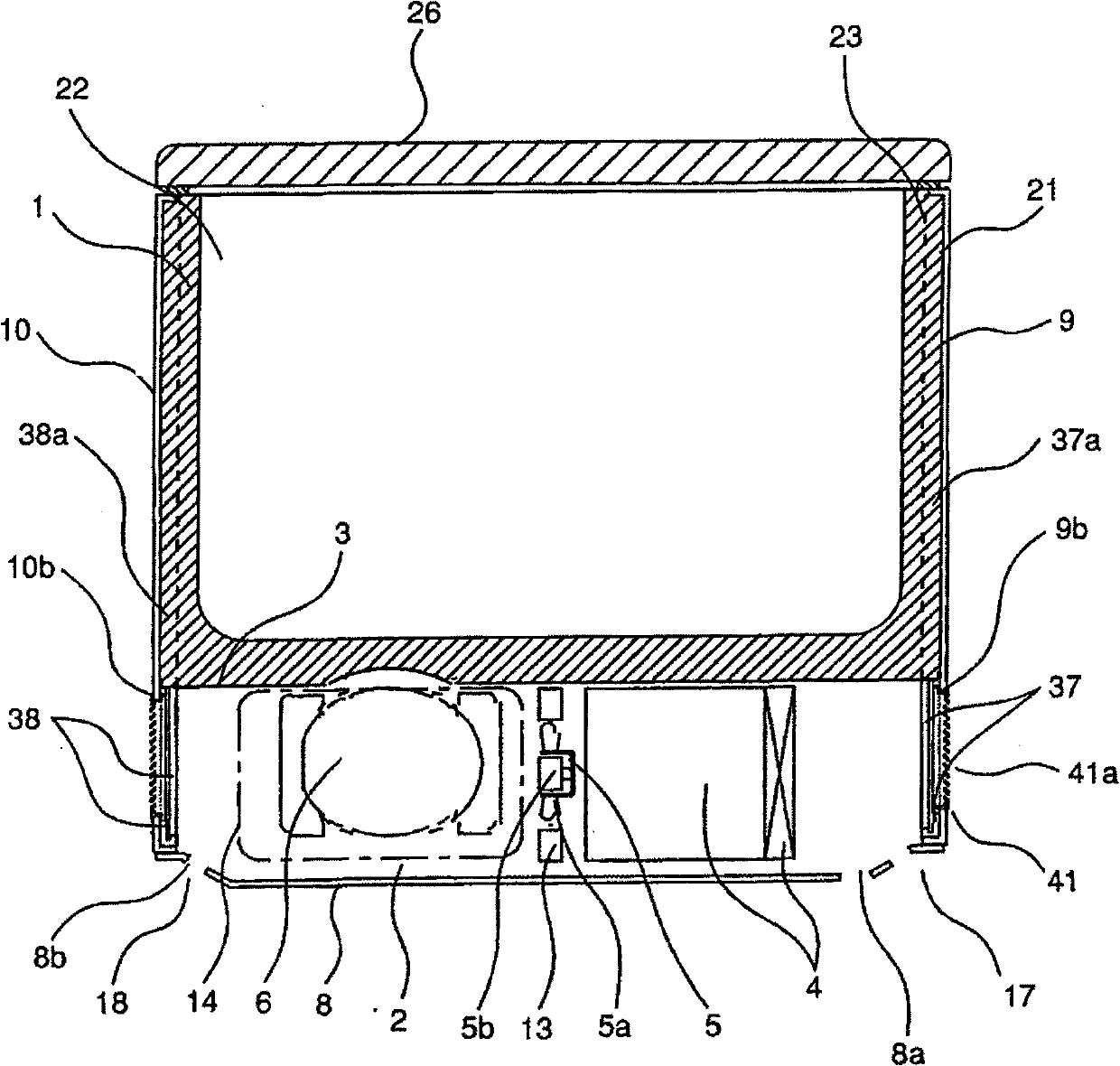

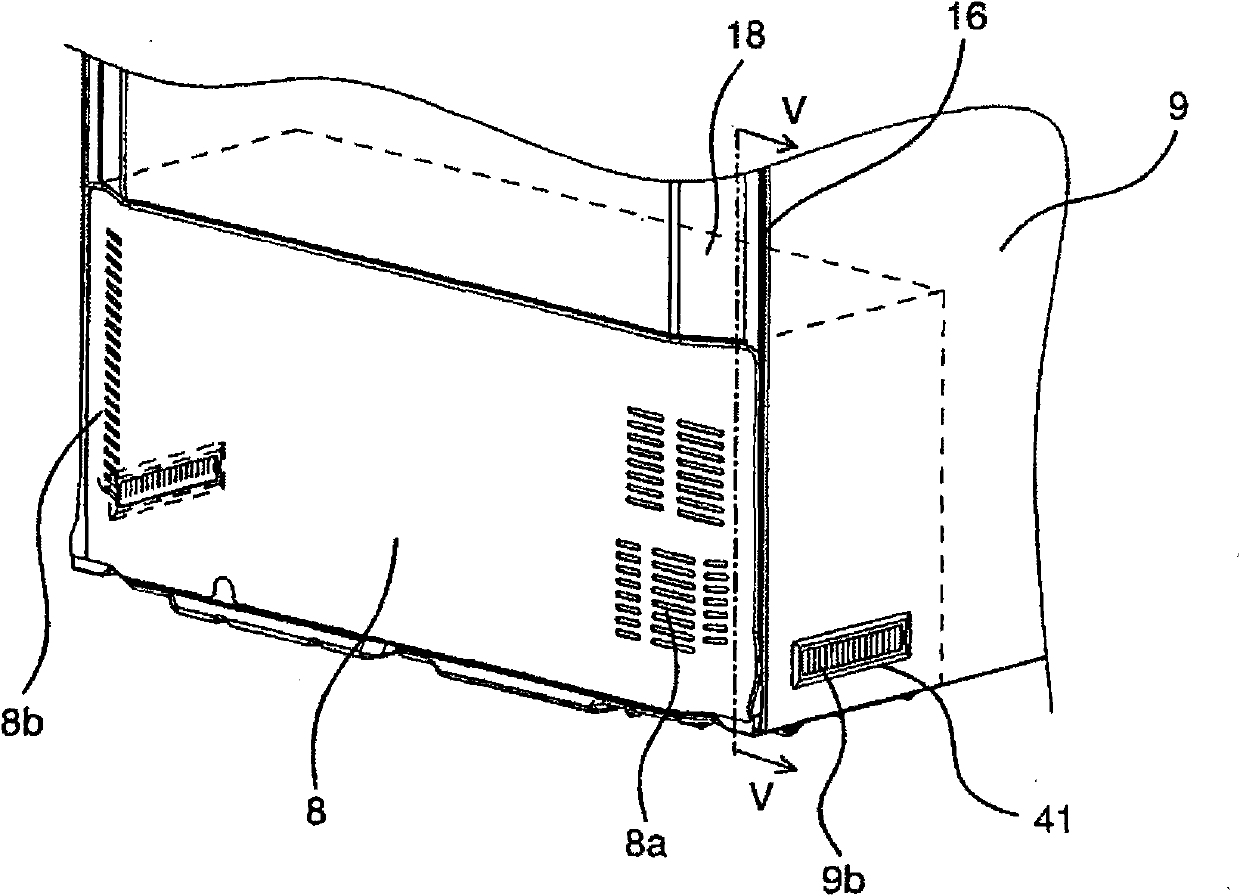

[0027] Embodiments of the present invention will be described below using the drawings.

[0028] First, refer to Figure 1 to Figure 6 The overall structure and operation including air flow of this embodiment will be described. Figure 7 and Figure 8 The arrows in indicate the flow of air, Figure 4 The arrows at indicate the flow of refrigerant.

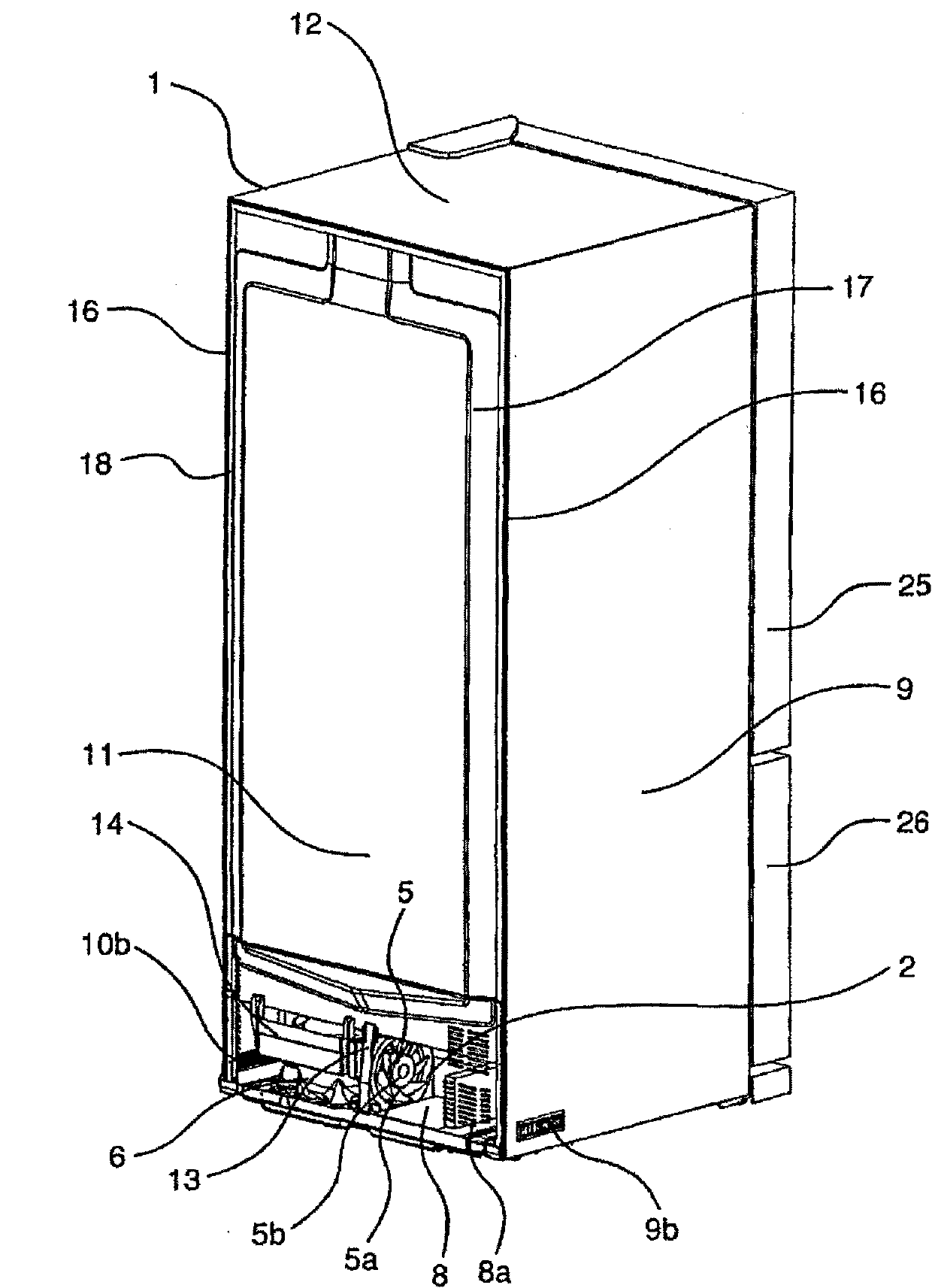

[0029] Such as figure 1 and figure 2 As shown, the main body 1 of the refrigerator includes: an outer case 21 formed of a top plate 12 forming an outer surface, side panels 9, 10, a back panel 11, a main body bottom plate 3, etc.; an inner case 23 forming a storage room 22; Heat insulating materials 24 such as heat insulating polyurethane foam filled between the inner boxes 23 . The outer case 21 is made of a metal plate such as a steel plate, and the inner case 23 is made of a synthetic resin such as ABS resin. A plurality of doors 25 and 26 for opening and closing a plurality of storage compartments 22 are provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com