High-temperature flue gas cooling equipment

A technology for cooling equipment and high-temperature flue gas, which is used in heat exchange equipment, lighting and heating equipment, damage protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

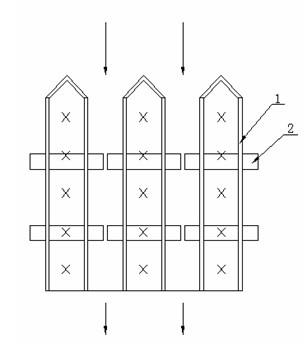

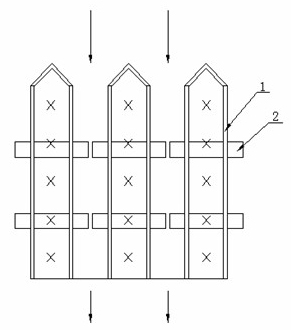

[0010] Such as figure 1 As shown, the high-temperature flue gas cooling equipment described in the present invention is composed of several plate members 1 to form several closed passages for the passage of high-temperature flue gas, and the cooling air is passed between the closed passages to form several heat exchange passage groups. The high-temperature flue gas exchanges heat with the cooling air through the wall of the plate member 1 . Due to the impact of the airflow, the plate member 1 will vibrate, which prevents dust from accumulating on the plate member 1 and ensures the use effect of the cooling device. A cylindrical connector 2 is arranged at a certain distance between the plate members 1 to prevent the plate members 1 from being greatly deformed during use and reducing the capacity of the high-temperature flue gas passage or the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com