Method and device for spraying printing ink on circuit board

A technology of spraying device and circuit board, which is applied in the secondary treatment of printed circuit, coating of non-metallic protective layer, etc. Qualification rate, the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

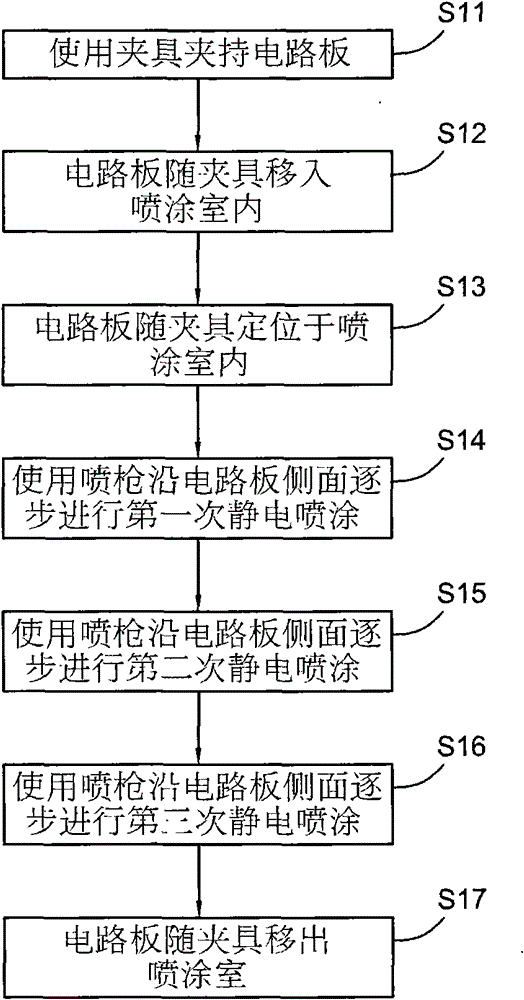

[0041] first look figure 1 Shown, disclose the flow chart of the ink spraying method of circuit board of the present invention, illustrate that the present invention comprises following implementation steps:

[0042] In step S11, use more than one clamp 3 clamping a circuit board 8 in the ink spray chamber 20 (matched figure 2 shown).

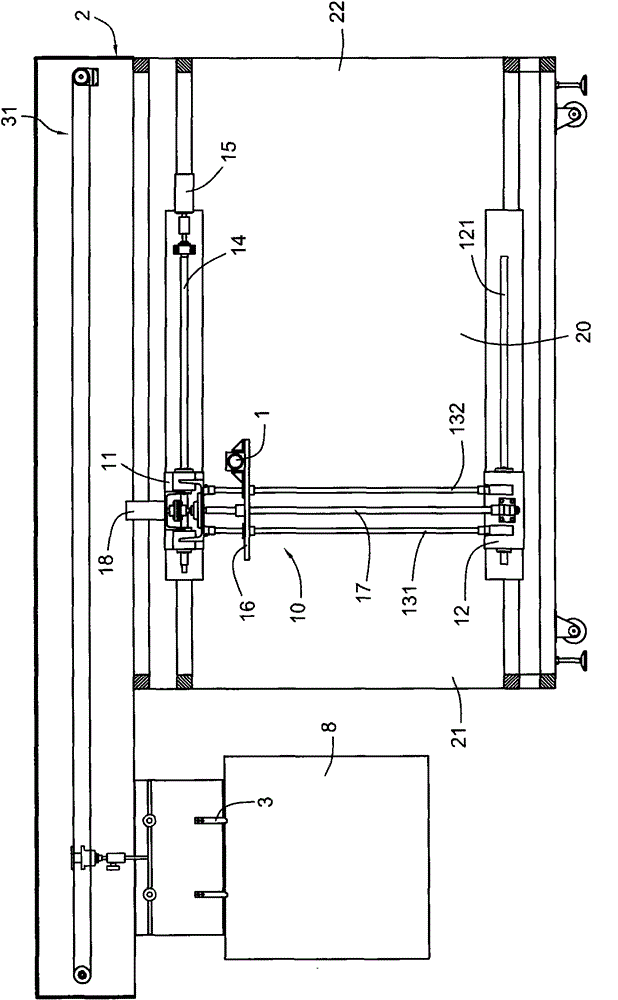

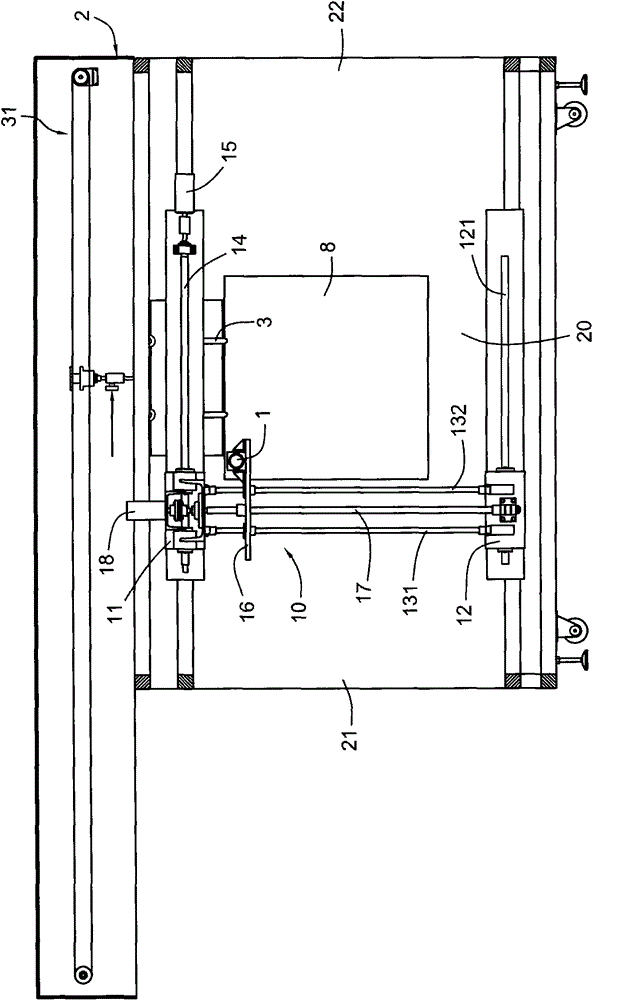

[0043] In step S12, the clamp 3 is moved into the spray booth 20 (with Figure 3 to Figure 5 shown), and the circuit board 8 is moved into the interior of the spray booth 20 with the fixture 3 .

[0044] In step S13, the fixture 3 is positioned in the spray booth 20 (with Figure 3 to Figure 5 As shown), the circuit board 8 is positioned inside the spray booth 20 along with the fixture 3 .

[0045] In step S14, use an ink spray gun 1 that can move more than two axially in the spraying chamber 20, and carry out the first electrostatic spraying step by step along the side of the circuit board 8 (with Figure 8 to Figure 11 As shown), the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com