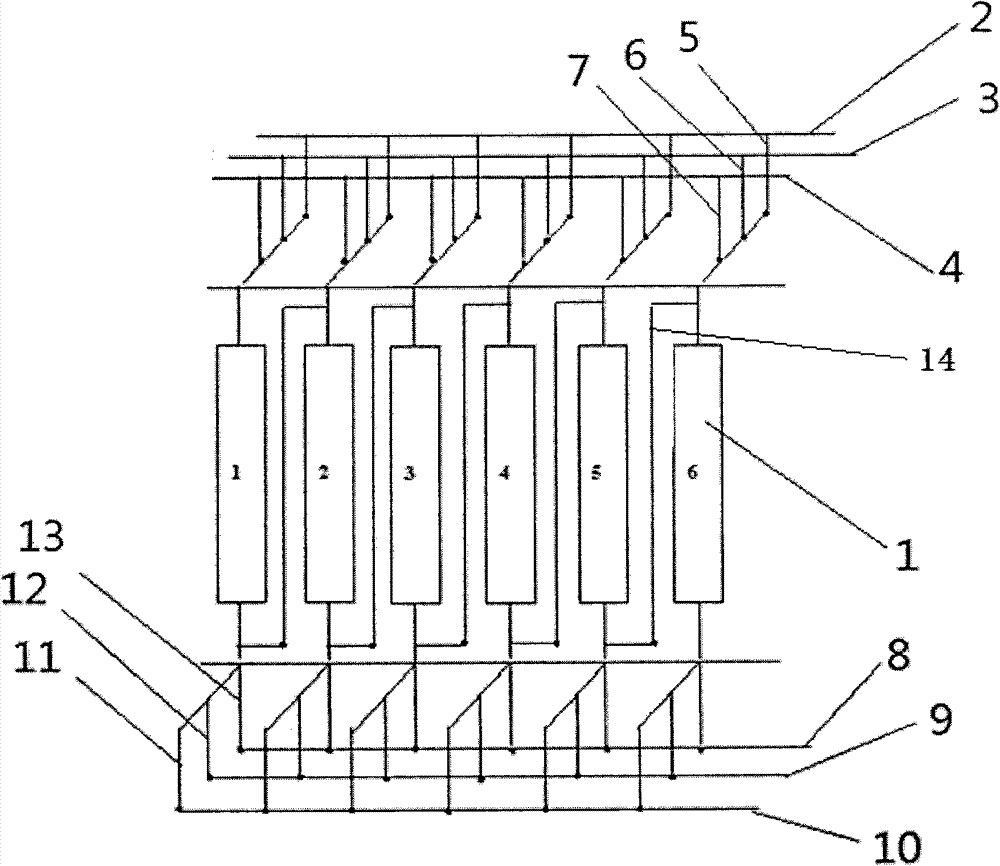

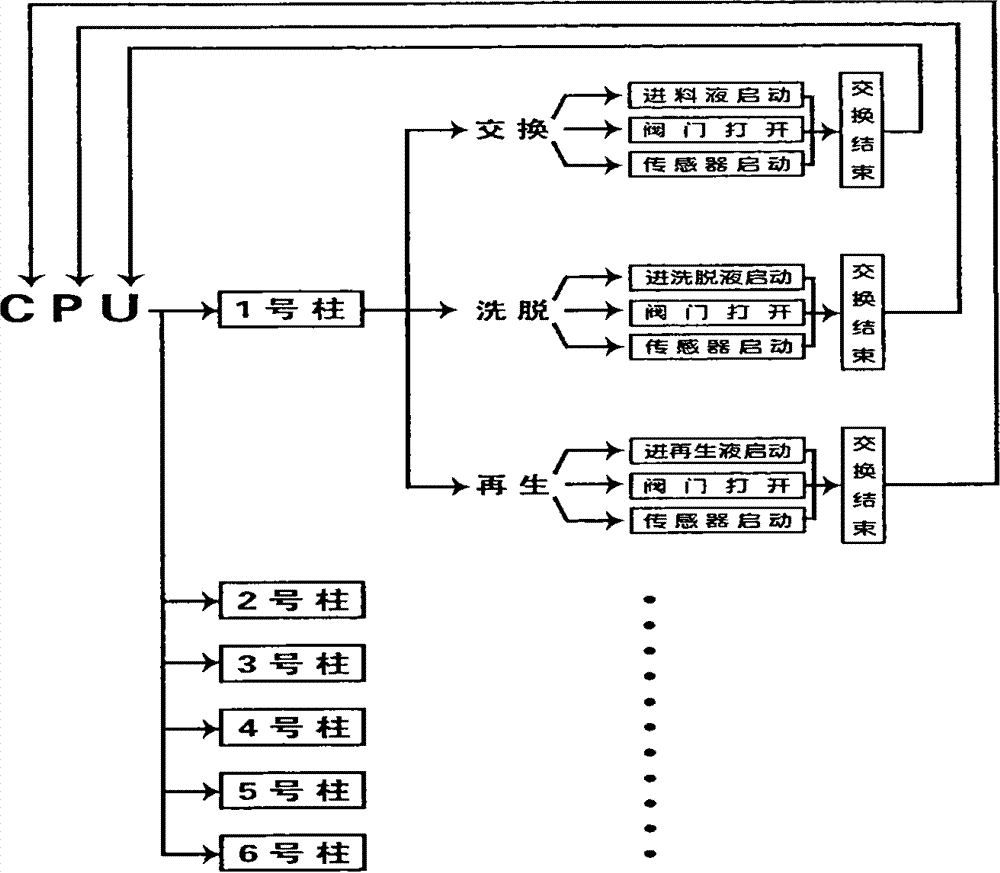

Continuous ion exchange unit for organic acid production

A continuous ion and exchange device technology, applied in ion exchange treatment device, ion exchange, ion exchange column/bed method, etc., can solve the problems of low utilization rate of ion exchange resin, long operation cycle of a single batch, and many equipment, pipelines and valves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is the process of removing cations from lactic acid. Using the method and device of the present invention, the feed liquid to be treated is the feed liquid after the second activated carbon decolorization of lactic acid production, with a concentration of 18%-19%, and a viscosity of 1.05cP-1.10cP. The temperature is 30-40°C, the ion exchange resin is a gel-type strong acid cation exchange resin, using seplite LSI-010 produced by Xi'an Lanxiao Technology Co., Ltd., the exchange time is 2h, and the feed flow rate is controlled at 5-10m 3 / h. The regenerant uses 4-7% hydrochloric acid solution, and the amount of regenerant is 1-3 times the volume of the resin bed. The cation removal rate of the product can reach more than 98%, and the product yield can reach more than 99%.

Embodiment 2

[0037] This embodiment is the process of removing anions from lactic acid. Using the method and device of the present invention, the feed liquid to be treated is the feed liquid after removing cations, with a concentration of 17.5%-18.5%, a viscosity of 1.05cP-1.10cP, and a temperature of 30-40°C. , The ion exchange resin is a macroporous weak base anion exchange resin, using seplite LSI-363 produced by Xi'an Lanxiao Technology Co., Ltd., the exchange time is 3h, and the feed flow rate is 8-12m 3 / h. The regenerant uses 5-7% alkali solution, and the amount of regenerant is 1-3 times the volume of the resin bed. The anion removal rate of the product can reach more than 98%, and the product yield can reach more than 99%.

Embodiment 3

[0039]The present embodiment is the process of removing cations and anions by citric acid. Using the method and device of the present invention, the feed liquid to be treated is 20%-22% citric acid solution, pH: 1-2. The ion exchange resin is a macroporous strong acid cation exchange resin, which is seplite D001 produced by Xi'an Lanxiao Technology Co., Ltd., and converted to H+ type with 4% Hcl before use. The exchange time is 3 hours, and the flow rate is controlled at 8-10m 3 / h.

[0040] In the exchange process of the present invention, the resin can all reach the industrial saturated exchange, and the exchange capacity of the resin can be fully utilized. The exchange regeneration process is carried out continuously, and the exchange regeneration is not carried out in the same bed, the utilization rate of the resin is increased by 30-50%, and the regeneration agent is saved. 50-60%, the discharge of waste liquid is reduced, and the pressure on environmental protection is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com