Electrostatic powder spray gun with built-in ion collector

An ion collector and electrostatic powder technology, applied in the direction of spray discharge device, etc., can solve the problems of easy collision of circuit rods, difficult to clean, inconvenient to clean, etc., and achieve the effects of strong integrity, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

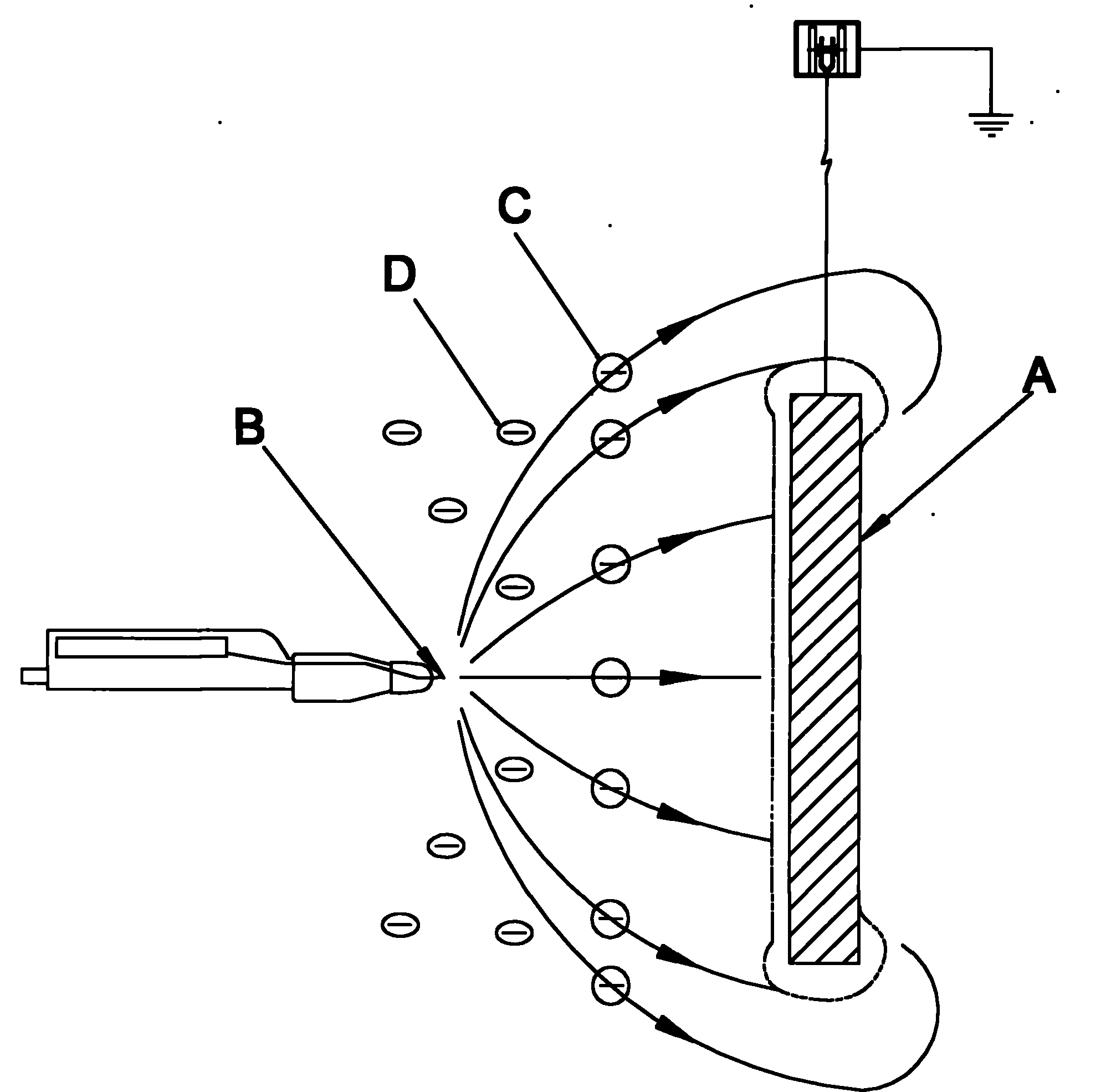

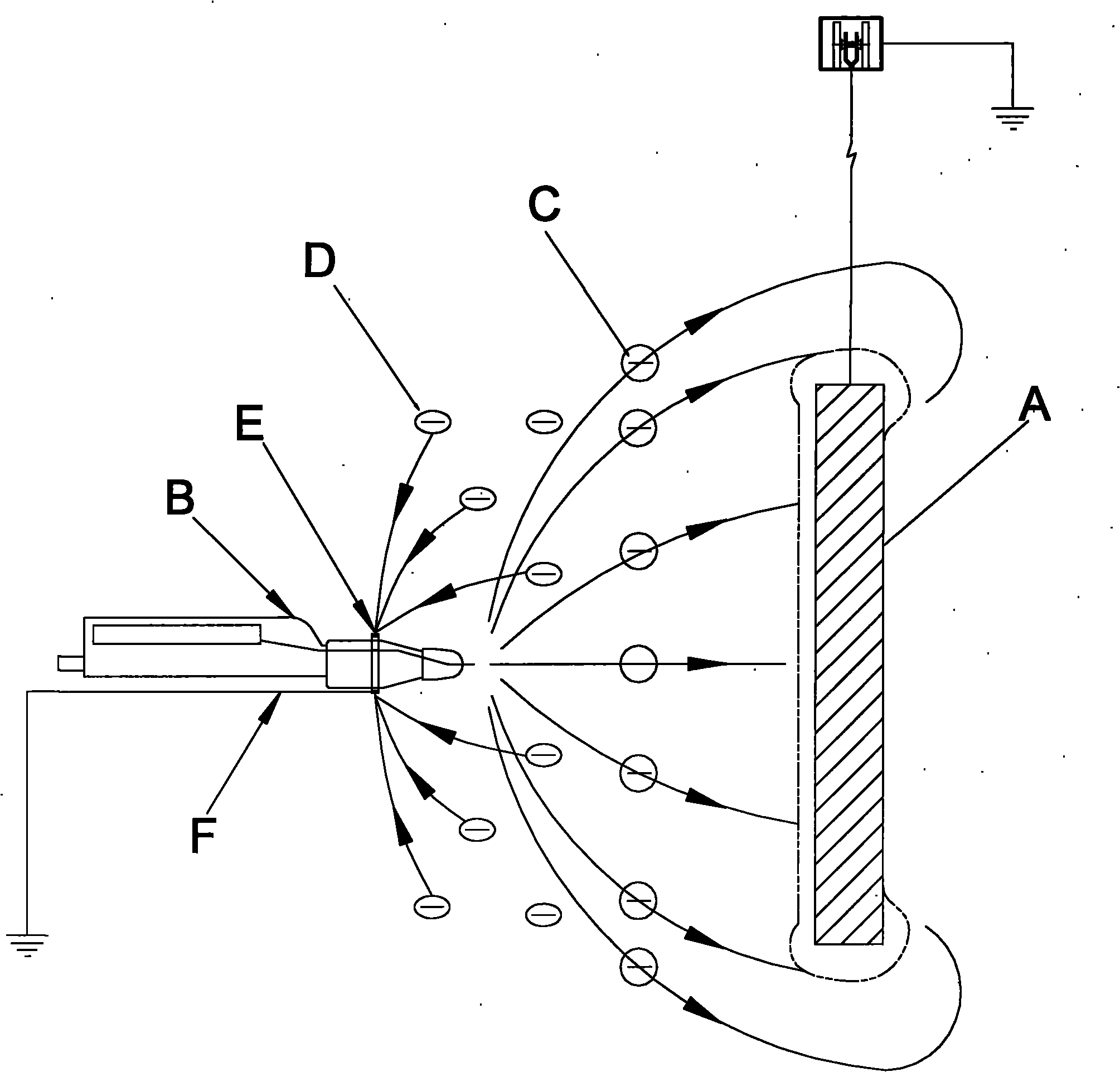

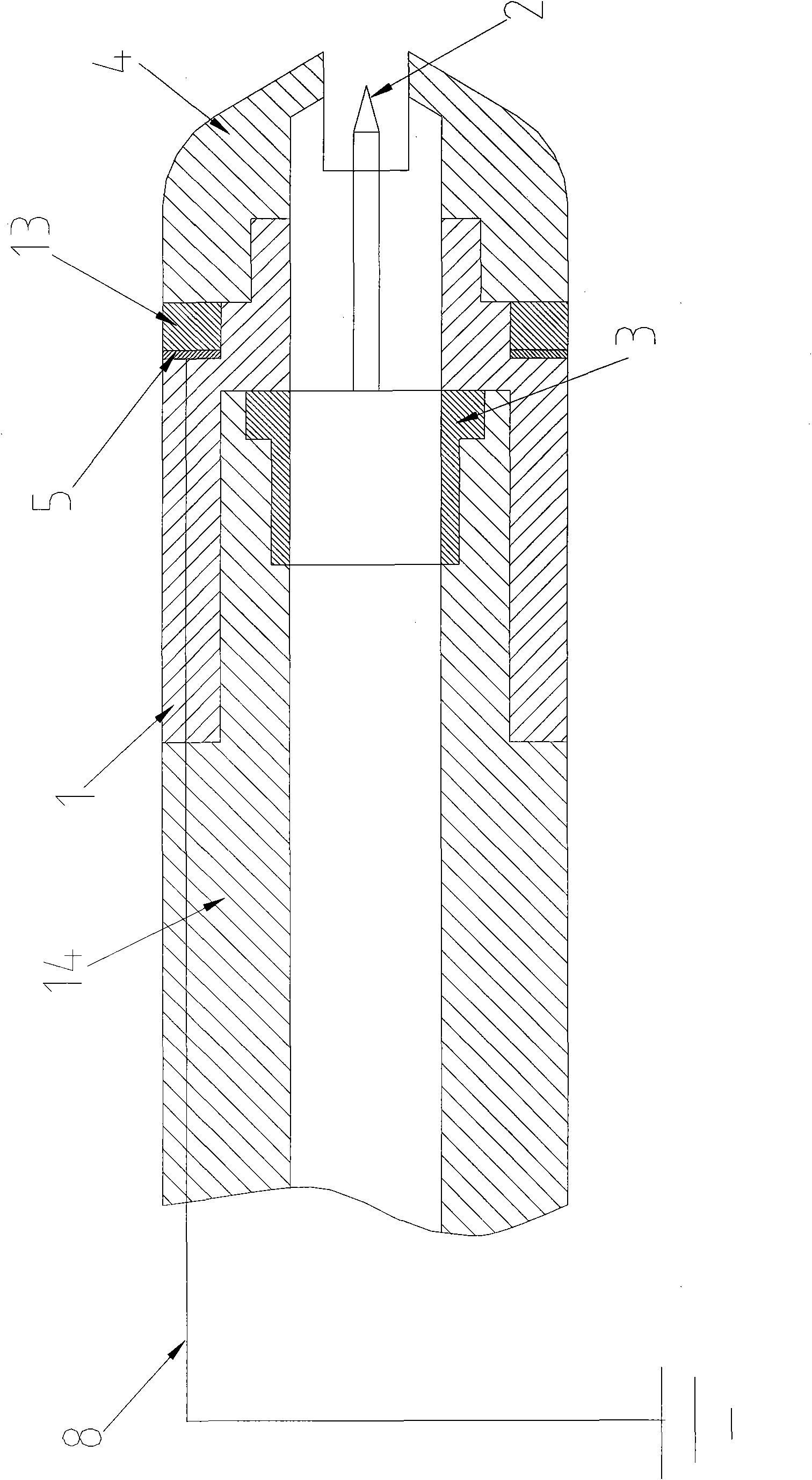

[0030] Example: Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, an electrostatic powder spray gun with a built-in ion collector of the present invention mainly includes an electrostatic spray gun barrel 14, an integrated spray gun locking cap 1, a discharge needle seat 3, a discharge needle 2, and a flat spray guide port 4 and the ion collection ring 5, the ion collection ring 5 is embedded in the front of the integrated spray gun locking cap 1, except the outer edge of the ion collection ring 5 is exposed, the rest of the ion collection ring 5 is embedded in the integrated spray gun locking cap 1 internal. A plurality of toothed electrodes 6 are arranged outside the ion collection ring 5 . The integrated spray gun locking cap 1 of the electrostatic spray gun is provided with a grounding wire channel 7 inside, and the grounding loop lead 8 is passed through the grounding wire channel 7, and one end of the grounding loop lead 8 is electrically connected to the ion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com