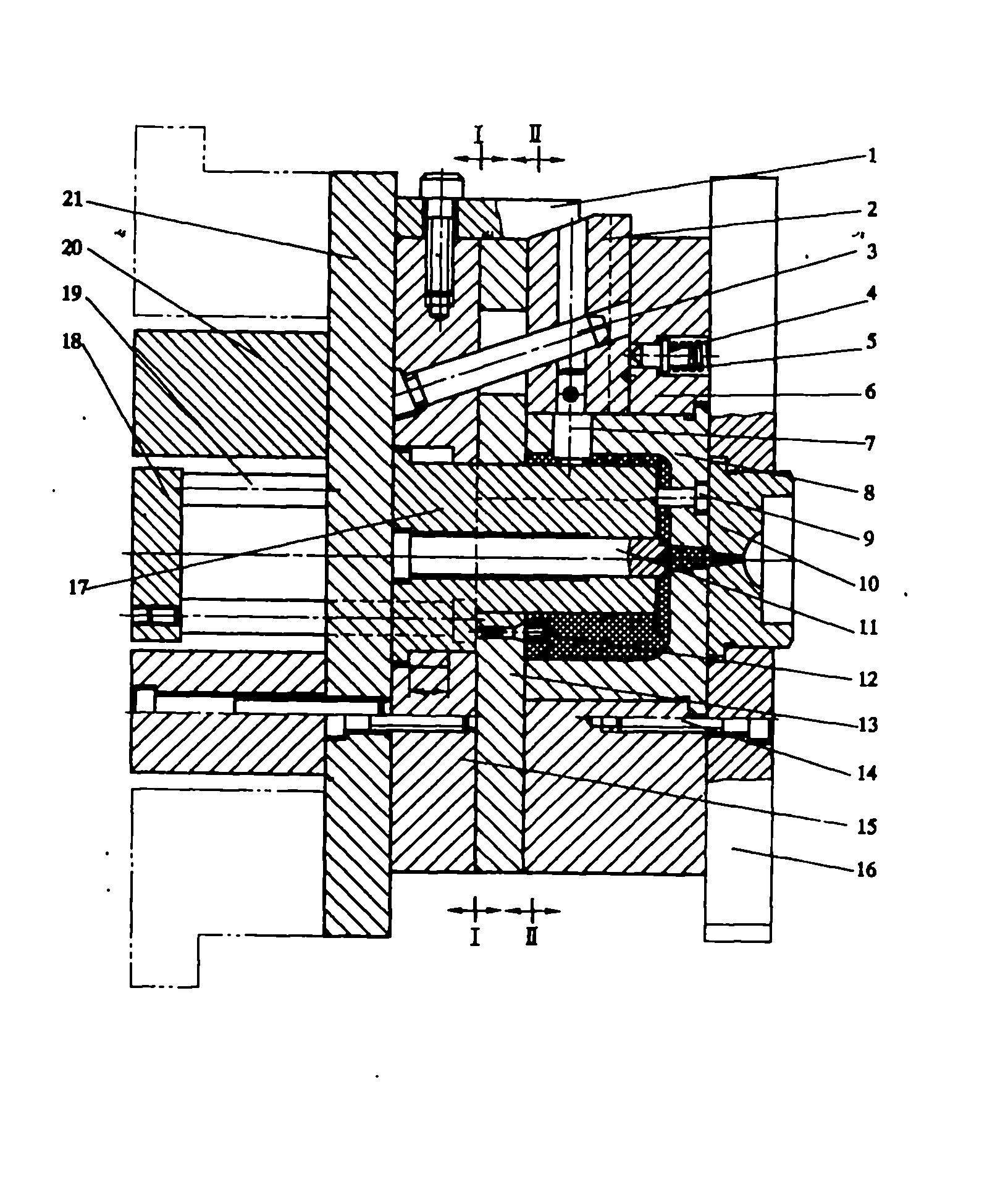

Mechanism with side mold core and sliding seat installed in fixing die and angle pin installed in moving die

A side core and mold mechanism technology, applied in the field of metal die-casting molds and plastic injection molds, can solve problems such as difficult processing and complex mold structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The figure shows a mold mechanism in which the side core and sliding seat are installed on the fixed mold, and the inclined guide post is installed on the movable mold. When opening the mold, the mold is divided by the I-I parting surface. Before the parting distance reaches the H value, the active force of the movable template 15 on the main core 17 is not large, so the main core remains motionless, and the oblique pin pulls the sliding seat 2 to extract the side core 7 . When the movable template 15 touches the shoulder surface of the main mold core 17, the main mold core starts to retreat together with the movable mold. Because the product has a strong wrapping force on the main mold core 17, the product presses the pusher plate 13 and retreats together, so II -II parting surface type. When releasing, the connecting push rod 19 promotes the push piece plate 13, because the insert positioning screw rod 12 is in the push piece plate 13 holes, so the product needs to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com