Cutter for machining eccentric groove

A technology of eccentric groove and cutting machine, which is applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment details, etc. It can solve the problems of affecting processing quality, part deformation, and poor versatility, so as to achieve good versatility, ensure processing quality, and process efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

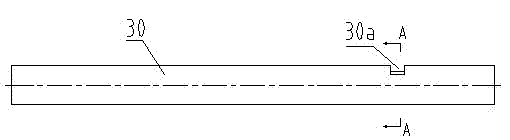

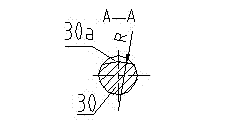

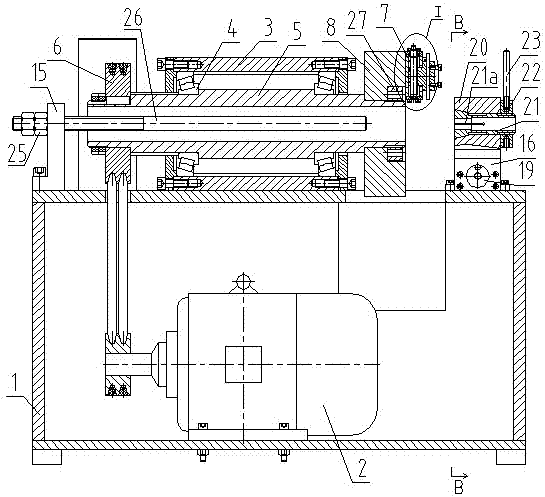

[0015] The present invention will be further described in detail below in conjunction with the drawings.

[0016] Such as Figure 3 to Figure 6 As shown, the cutting machine for processing eccentric grooves includes a machine table 1, a motor 2, a hollow main shaft 5 arranged on the machine table 1 through a bearing seat 3 and a bearing 4, and a pulley 6 connected to the motor 2 and the main shaft 5. 5 is also provided with a tool holding mechanism 7 and a material clamping mechanism on the machine table 1. The tool holding mechanism 7 includes a cutter head 8 fixed to one end of the spindle 5 by a lock nut 27, and is fixed to the end face of the cutter head 8 A square box-shaped mounting seat 9, a screw rod 11 mounted in the mounting seat 9 through bearings 10 at both ends, a sliding seat 12 threadedly connected with the screw rod 11, and axially positioned shoulders are provided at both ends of the screw rod 11, The two shoulders are respectively in contact with the end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com