Arc welding method and arc welding system

An arc welding method and arc welding technology are applied to arc welding equipment, welding equipment, manufacturing tools, etc., and can solve problems such as deterioration of the appearance of the weld bead and occurrence of spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

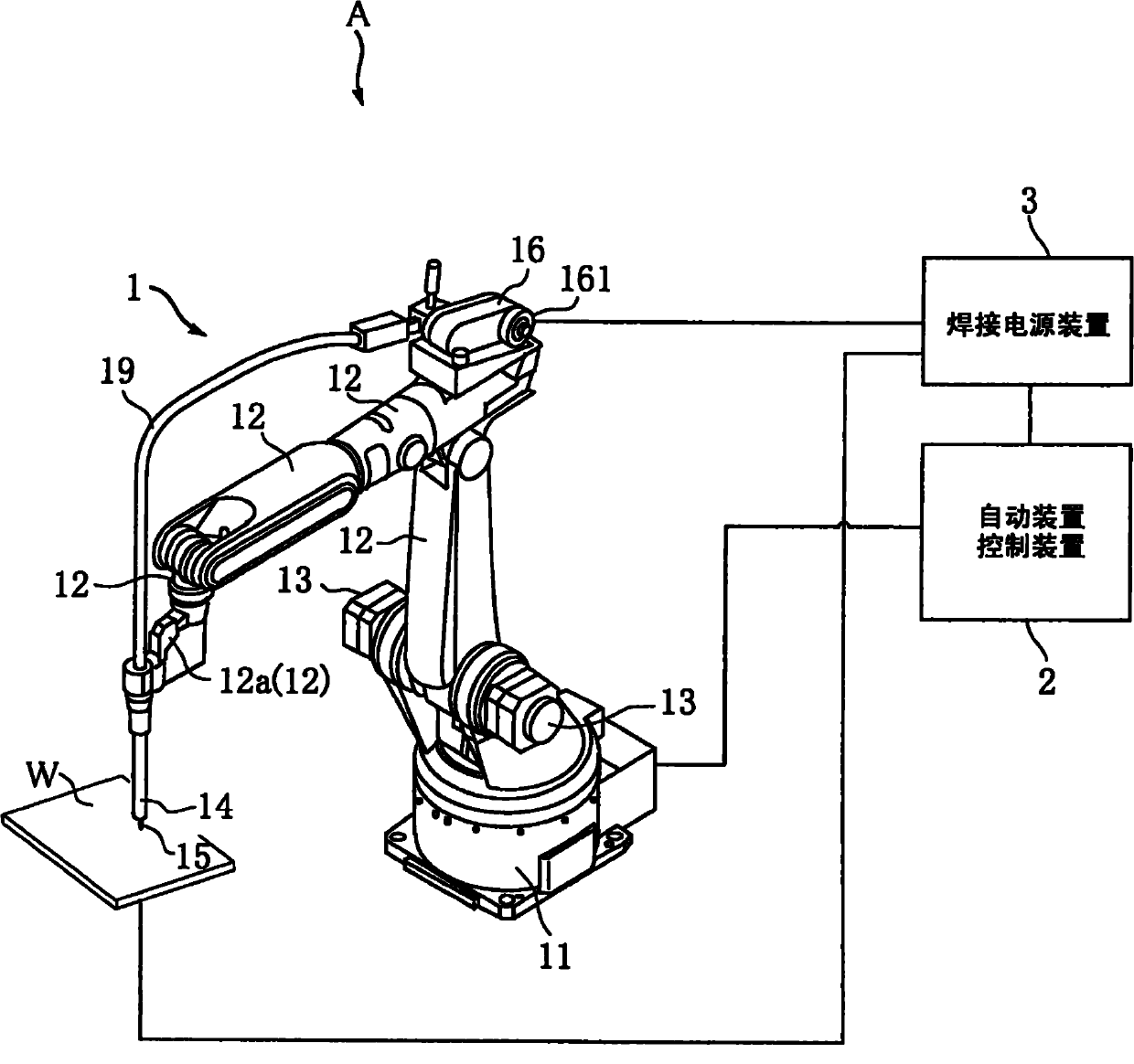

[0094] figure 1 It is a configuration diagram showing an example of the welding system according to the first embodiment of the present invention.

[0095] figure 1 The illustrated welding system A has a welding robot 1 , a robot control device 2 , and a welding power supply device 3 . The welding robot 1 automatically performs arc welding on the welding base material W, for example. The welding robot 1 has a base member 11 , a plurality of arms 12 , a plurality of motors 13 , a welding torch 14 , a welding wire feeder 16 , and a coil guide 19 .

[0096] The base member 11 is fixed at a suitable position such as the ground. Each arm 12 is connected to the base member 11 via a shaft.

[0097] The welding torch 14 is provided at the front end of the arm part 12 a provided at the front end of the welding robot 1 . The welding torch 14 guides a welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com