Pulsed arc welding method of carbon oxide

A carbon dioxide, pulsed arc technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem of more sputtering, and achieve the effect of improving the appearance of the weld bead, suppressing sputtering, and reducing the occurrence of sputtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

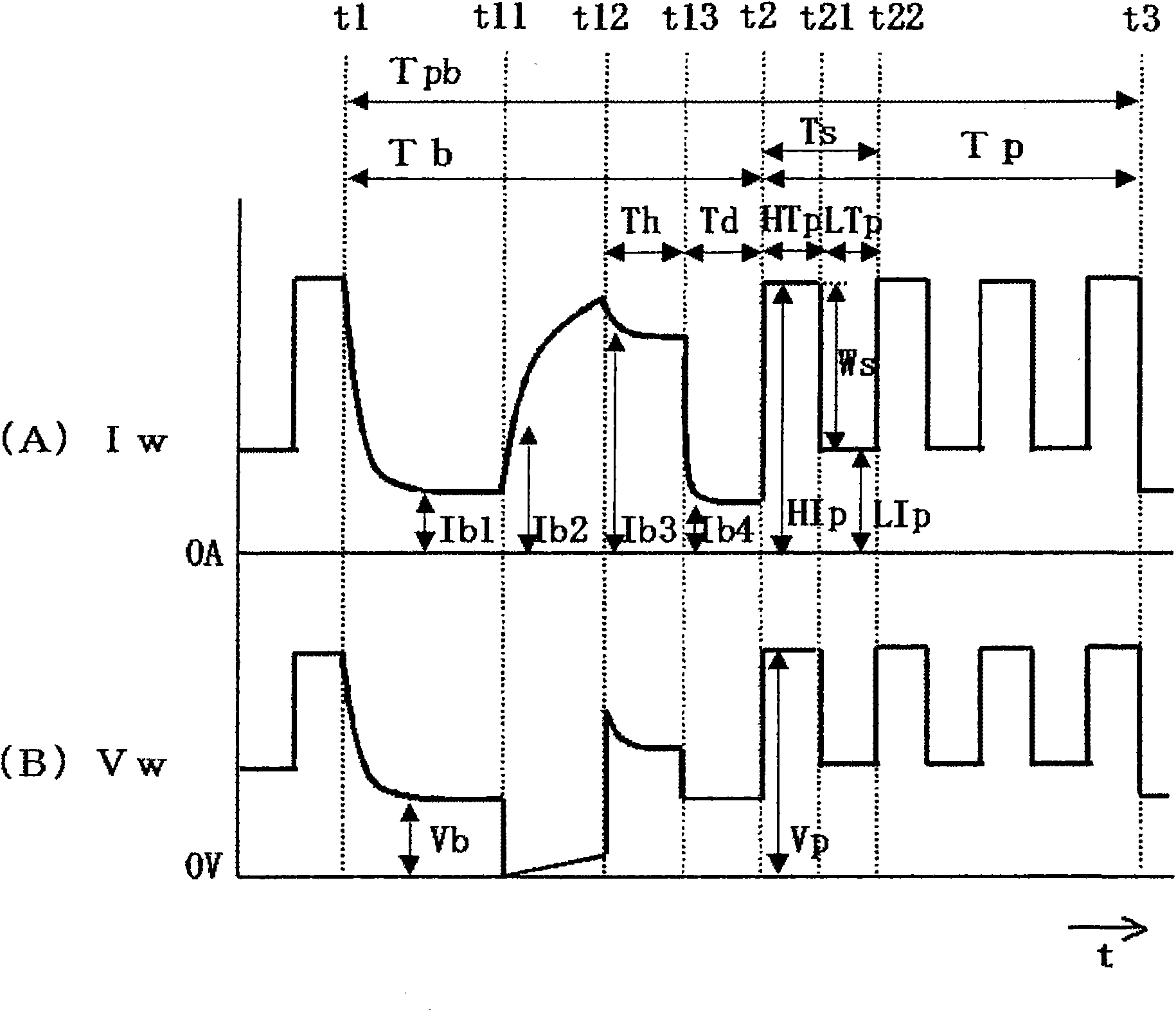

[0037] figure 1 It is a current-voltage waveform diagram showing the carbon dioxide pulse arc welding method according to the embodiment of the present invention. The graph (A) shows the temporal change of the welding current Iw, and the graph (B) shows the temporal change of the welding voltage Vw. This figure shows the case of a carbon dioxide pulse arc welding method using a shielding gas mainly composed of carbon dioxide. Hereinafter, description will be made with reference to this figure.

[0038] In the carbon dioxide pulse arc welding method according to the embodiment of the present invention, the pulse period Tpb at times t1 to t3 is formed of two periods. The first period is the base period Tb from time t1 to t2, and the second period is the peak period Tp from time t2 to t3. Therefore, welding is repeated with the base period Tb and the peak period Tp as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com