Self-circulation anaerobic reactor

An anaerobic reactor and container technology, applied in anaerobic digestion treatment and other directions, can solve problems such as unfavorable gas mixing with influent water, inability to generate internal circulation, and reactor flocculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

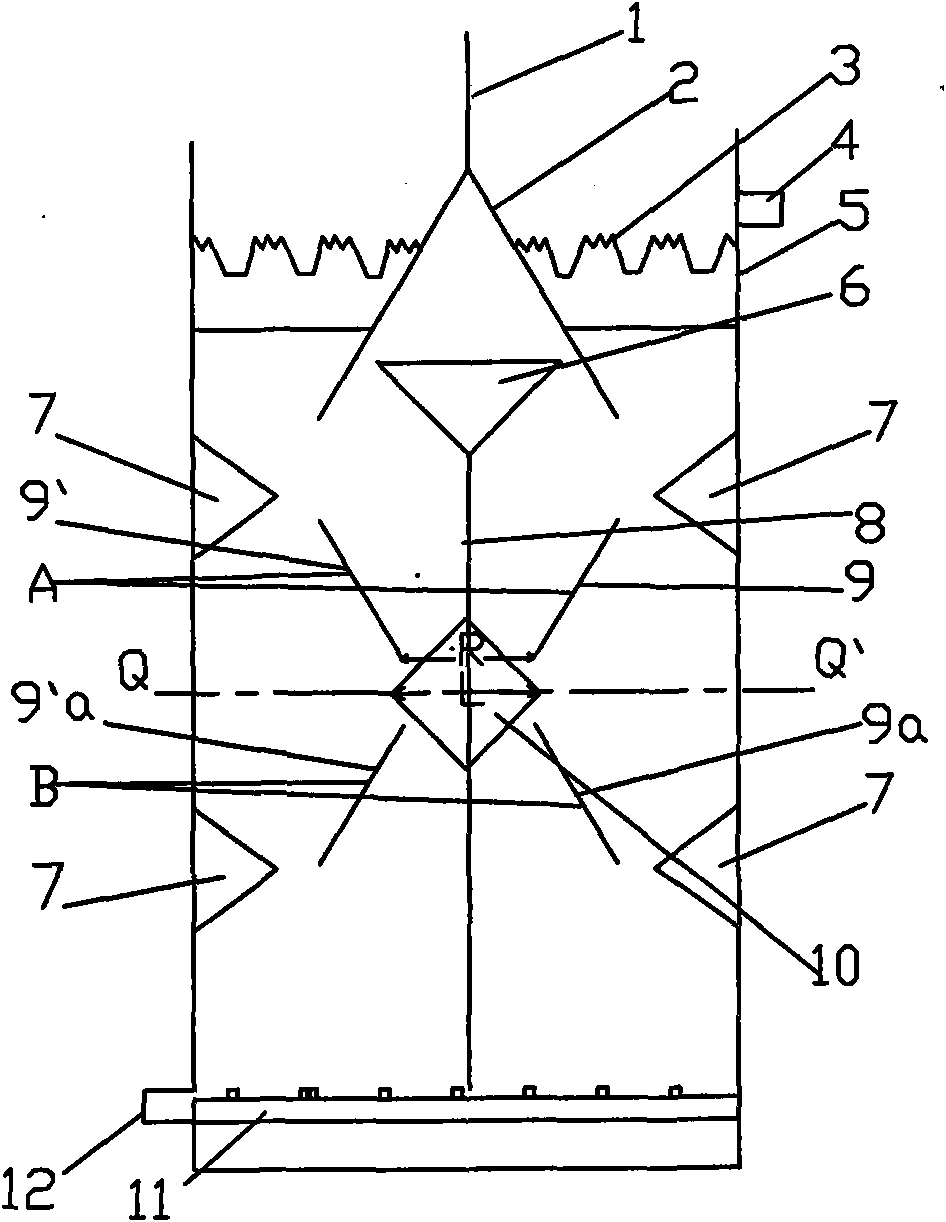

[0014] Embodiment 1: This self-circulating anaerobic reactor comprises a container 5, a water inlet pipe 12 communicating with the bottom of the container 5, a water distribution system 11 located at the bottom of the container 5 and connected with the water inlet pipe 12, and an overflow is provided on the top of the container 5. Flow weir 3, water outlet pipe 4 and a gas collection hood 2, the gas collection hood 2 is connected with the gas outlet pipe 1, the gas collection hood 2 is composed of two boards, the tops of the two boards intersect, and the angle between them is 45° There is a reflux funnel 6 and two layers of baffles on the bottom of the gas collection hood 2, and each layer of baffles has two plates that are installed obliquely in the container 5 but do not intersect. The vertical line in the middle is symmetrical; in this embodiment, the first layer of baffles A is composed of a plate 9 and a plate 9', and the plate 9 and the plate 9' are installed obliquely in...

Embodiment 2

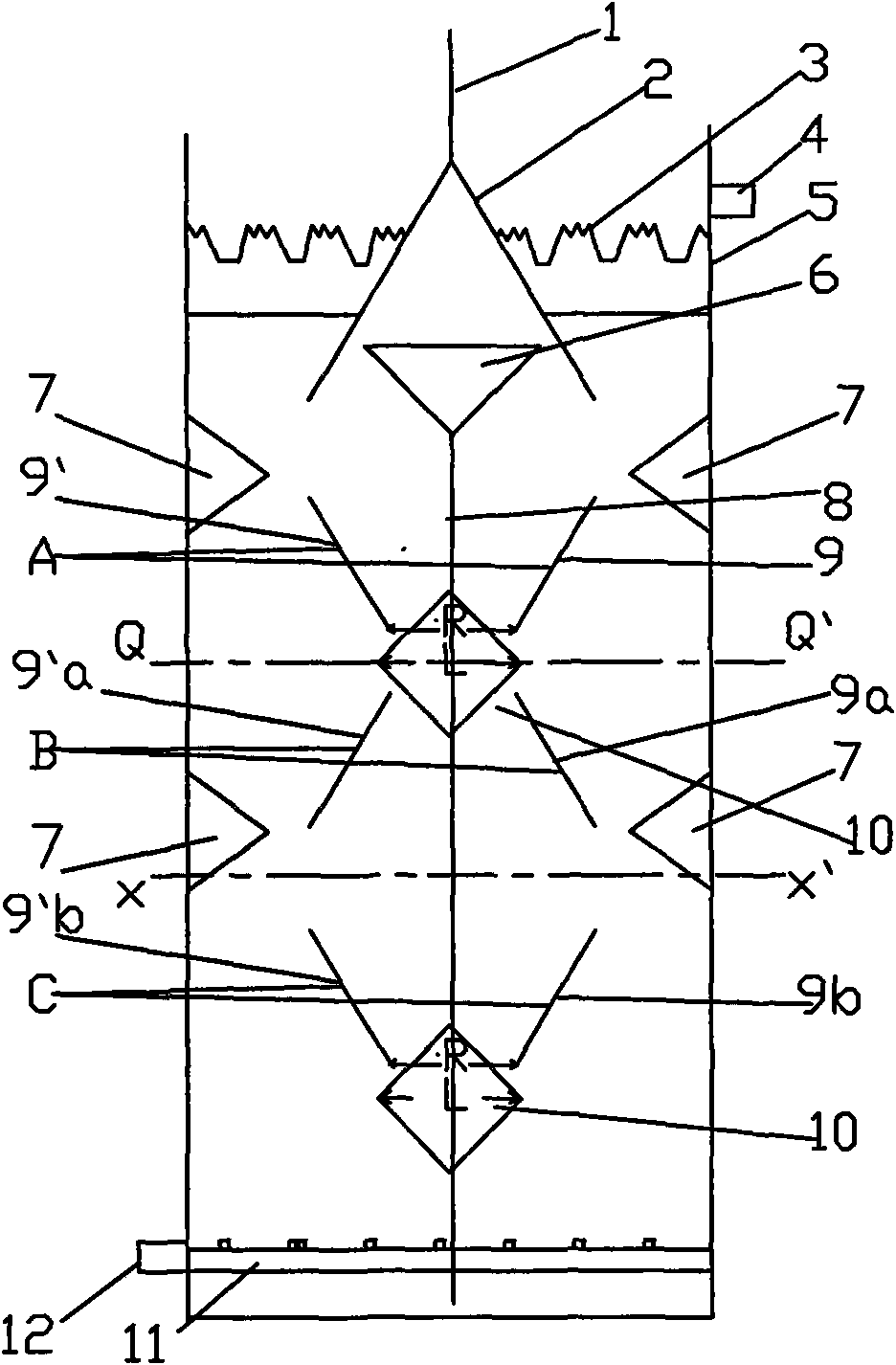

[0015] Embodiment 2: There are three layers of baffles on the lower side of the gas collecting hood 2 in this embodiment, the third layer of baffles C is made up of plate 9b and plate 9'b, the third layer of baffles C is connected with the second layer of baffles The baffle B is symmetrical with the horizontal line XX' in the middle of them, and the plate 9b and the plate 9'b in the third baffle C become an inverted "eight" shape; There is a shunt 10 . Other structures are the same as in Embodiment 1. The return pipe 8 communicated with the return funnel 6 passes through the gap in the middle of the three-layer baffle, and its outlet is located at the bottom of the container 5 . In addition to selecting 2-3 layers of baffles for use in the bottom of the gas collecting hood 2, 4 or 5 layers of baffles can also be selected according to the depth of the container in the self-circulating anaerobic reactor. If it is 4 layers of baffles, then the fourth layer of baffles and the th...

Embodiment 3

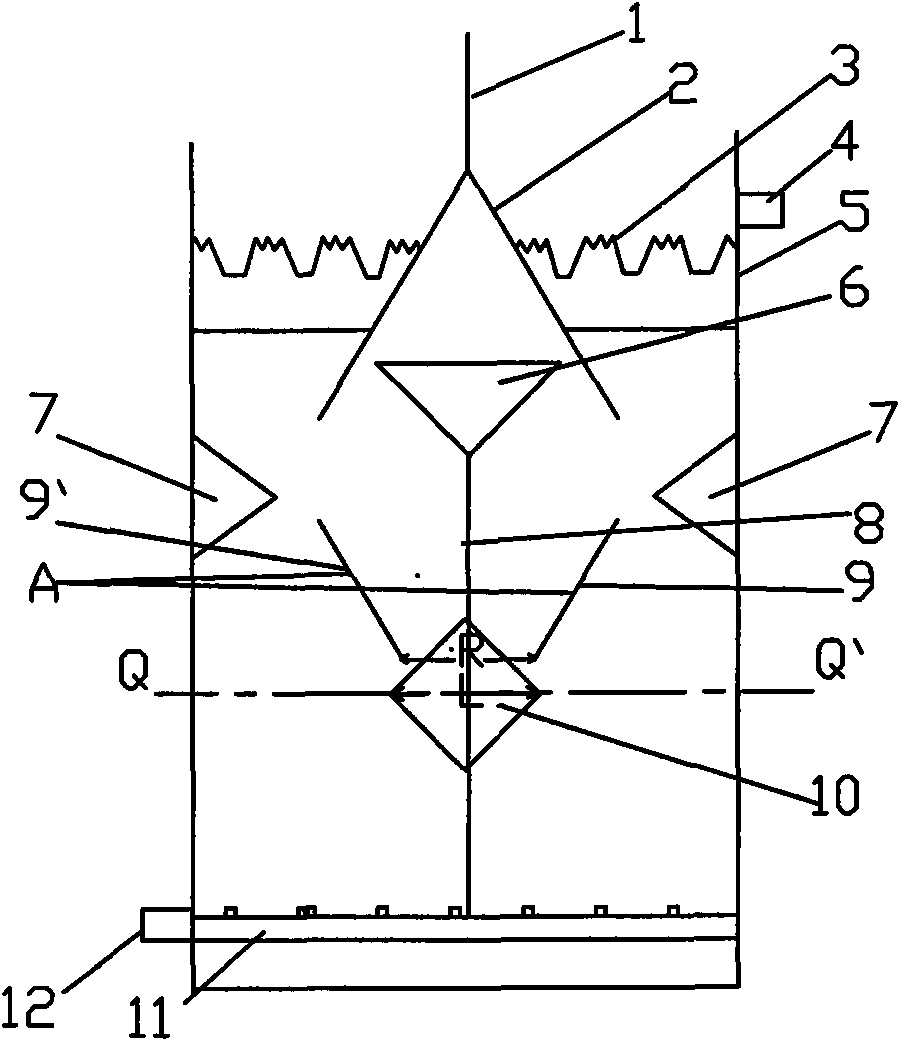

[0016] Embodiment 3: a gas collection hood 2 is arranged in the present embodiment, and a return funnel 6 and a deck of baffles are arranged below the gas collection hood 2. This baffle is made up of a plate 9 and a plate 9', and the plate 9 and The plates 9' are installed obliquely in the container 5, but these two plates do not intersect, and the angle formed by their extension lines is 45 °, and the plates 9 and 9' are symmetrical with the vertical line in the middle of them; and, the two plates The horizontal distance between the plates is closer to the end of the gas collecting hood than the end of the long horizontal distance between the two plates, forming an inverted "eight" shape; Distributor plate 7 is placed on the container inner wall, and the structure and installation position of water inlet pipe 12, water distribution system 11, overflow weir 3, water outlet pipe 4, gas collecting hood 2, return flow funnel 6 and return pipe among the present embodiment are all c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com