Conductive fabric, fabric circuit and method for forming the same

A technology of conductive fabrics and fabrics, which is applied in the direction of fabrics, multi-strand fabrics, textiles, and papermaking, and can solve problems such as short circuits and injuries of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

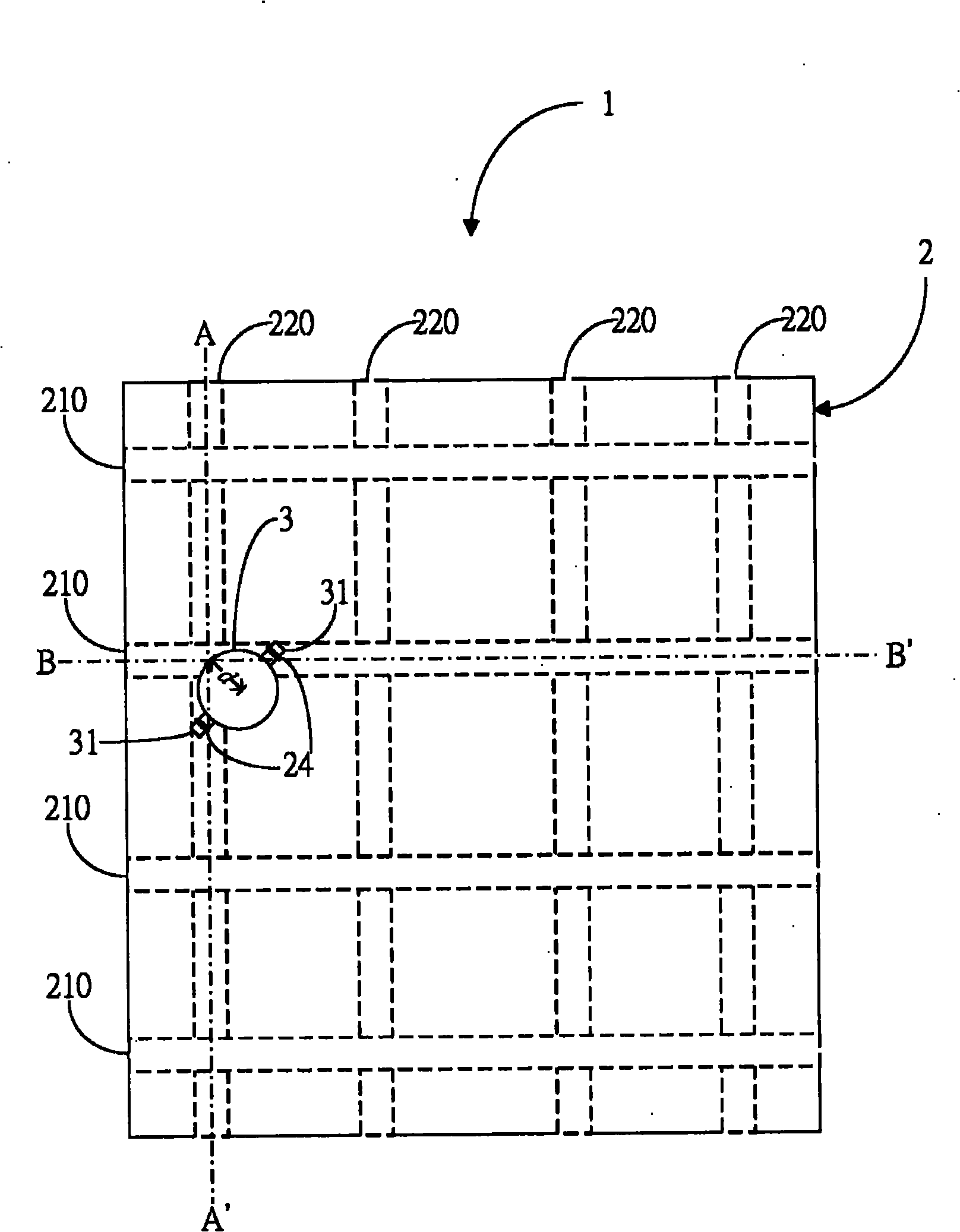

[0022] see Figure 1A , which shows a fabric circuit 1 of a first embodiment of the present invention. The fabric circuit 1 can be integrated into a part of any conventional fabric or cloth to extend the original function of the fabric or cloth. Specifically, the fabric circuit 1 includes a conductive fabric 2 and at least one electronic component 3 attached to the conductive fabric 2 . The conductive fabric 2 of the present invention is basically a fabric capable of electrically connecting any electronic components such as light emitting diodes (LEDs), chips or similar materials.

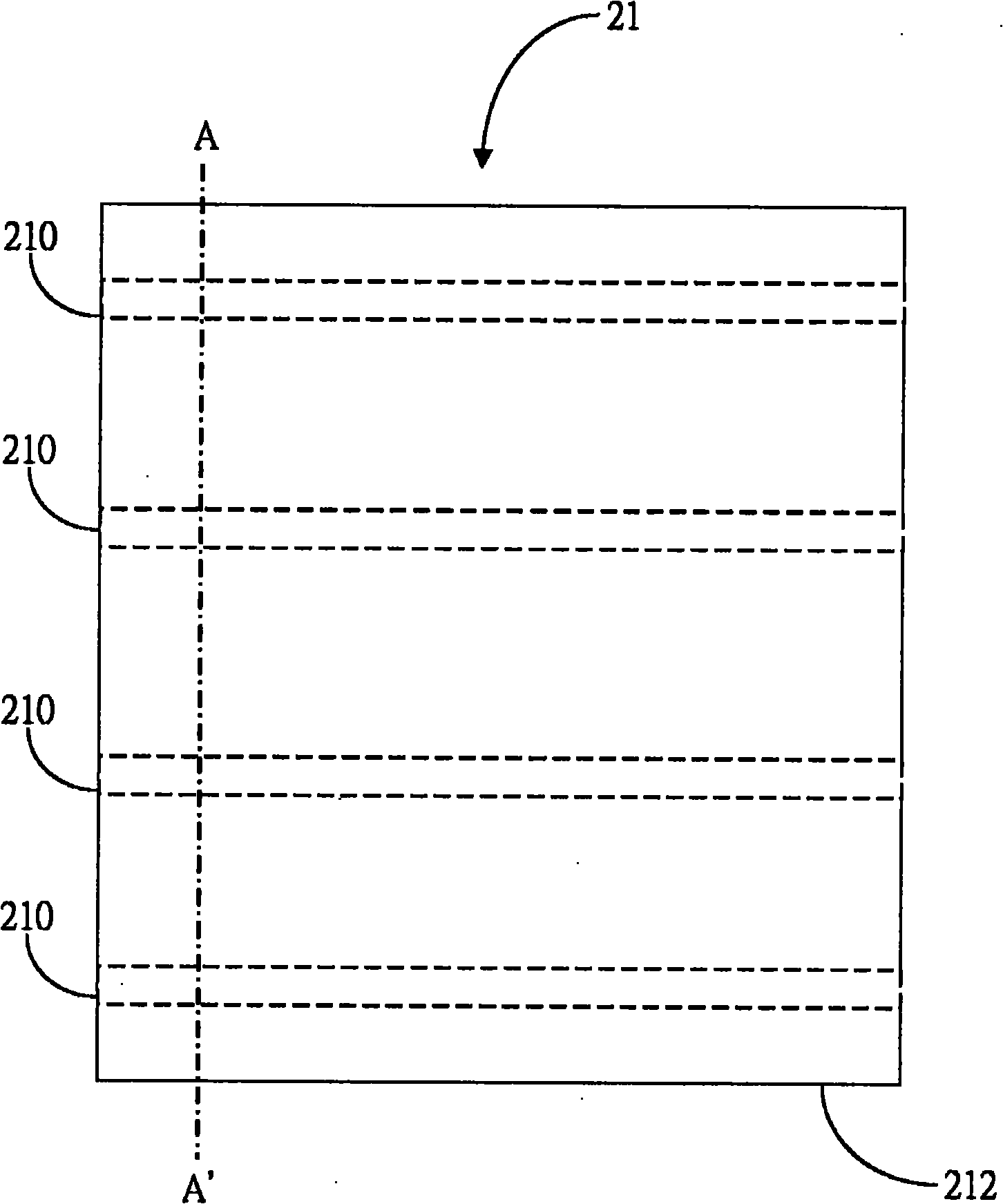

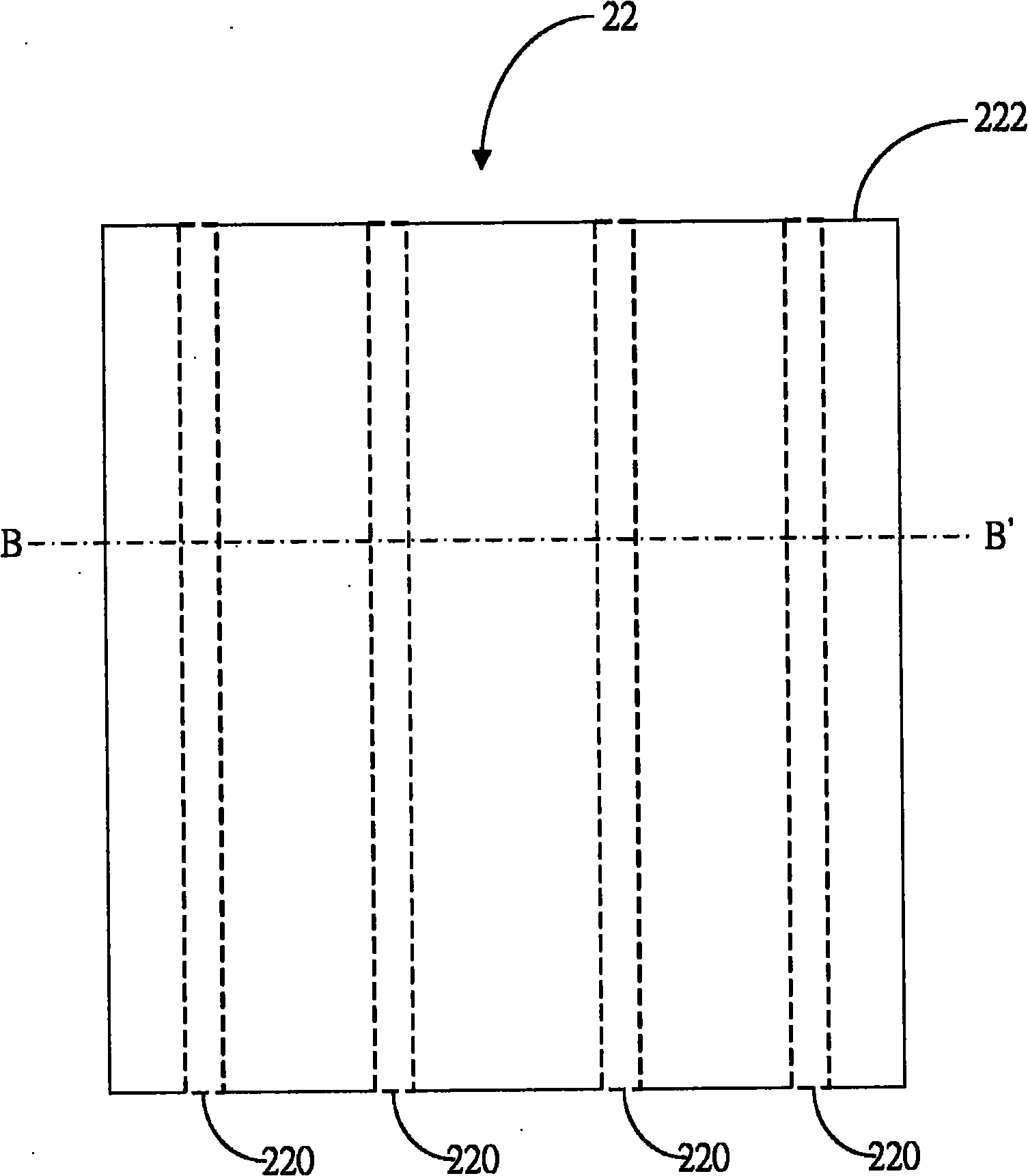

[0023] Then please refer to Figure 1B and Figure 1C . The conductive fabric 2 includes a first layer 21 and a second layer 22 . The first layer 21 has four first conductive threads 210 and a plurality of first non-conductive threads 212 . The first conductive threads 210 are flexible and are woven into the first non-conductive threads 212 . Likewise, the second layer 22 has four second cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com