Cab sliding device of engineering machinery

A technology of construction machinery and sliding devices, which is applied to earth movers/shovels, construction, etc., can solve the problems of difficulty in obtaining flatness, excessive or insufficient bending degree, and labor-intensive assembly, so as to achieve easy disassembly and easy to ensure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

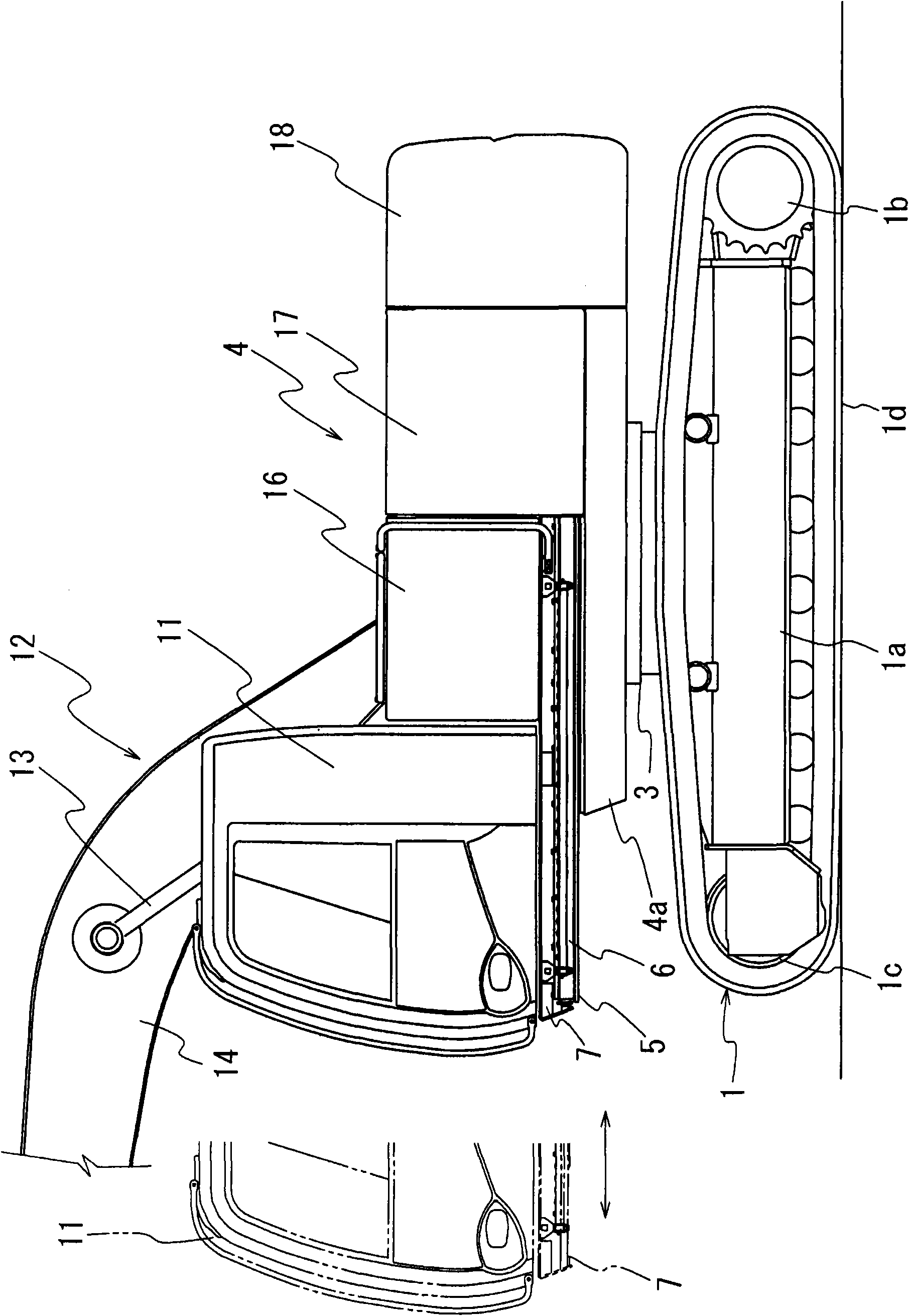

[0092] figure 1 It is a side view showing an example of a construction machine to which the present invention is applied. Attached body symbol 1 represents the undercarriage body, and the structure of this undercarriage body 1 is, has side frame 1a on the left and right side of the undercarriage body frame that swivel device 3 is arranged on the upper part, is installed in the rear portion of this side frame 1a by traveling motor. (not shown) driving wheel 1b driven, driven wheel 1c is installed on the front portion of side frame 1a, and crawler belt 1d is hung on driving wheel 1b and driven wheel 1c. The upper rotating body 4 is rotatably arranged on the running body frame through the rotating device 3 .

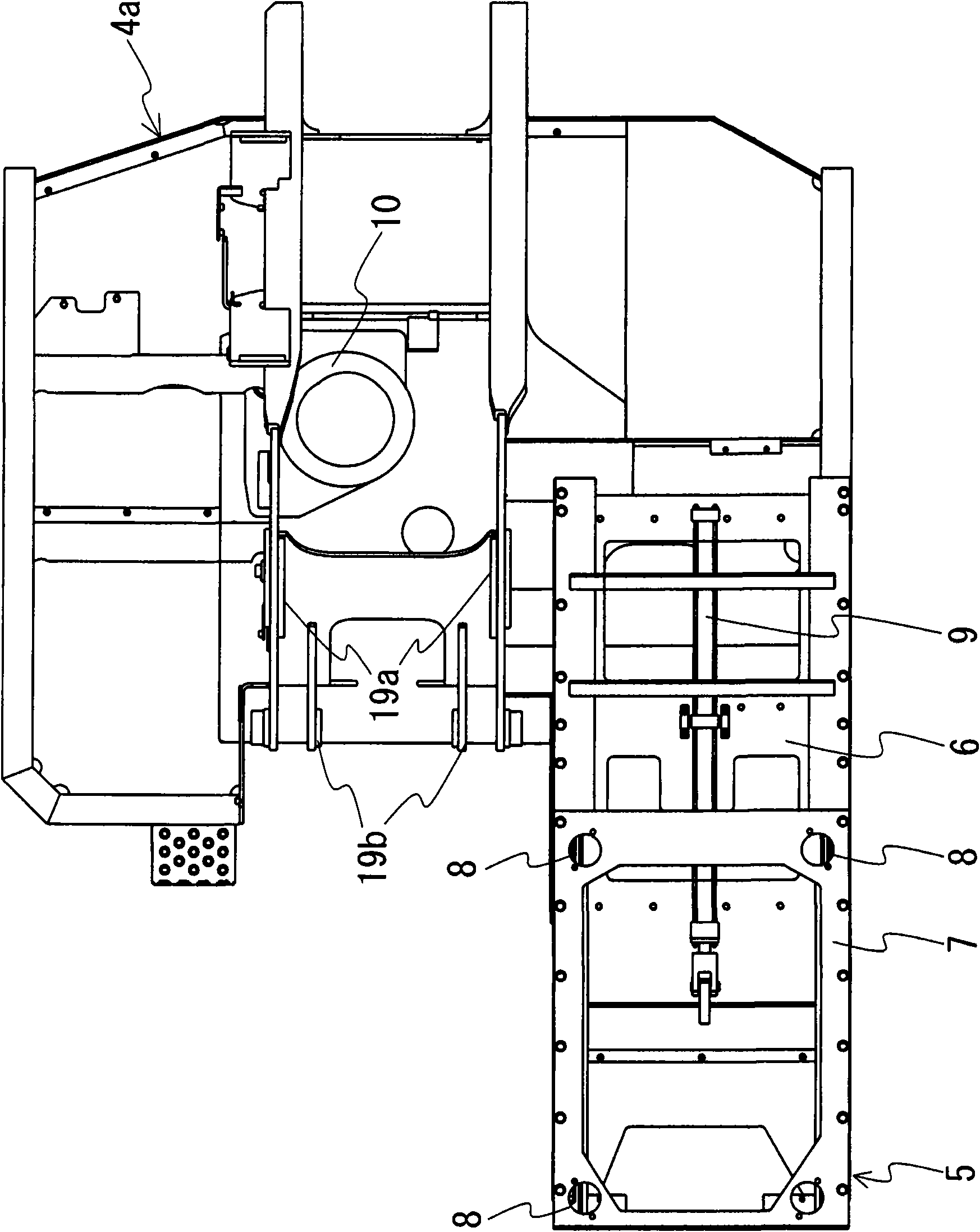

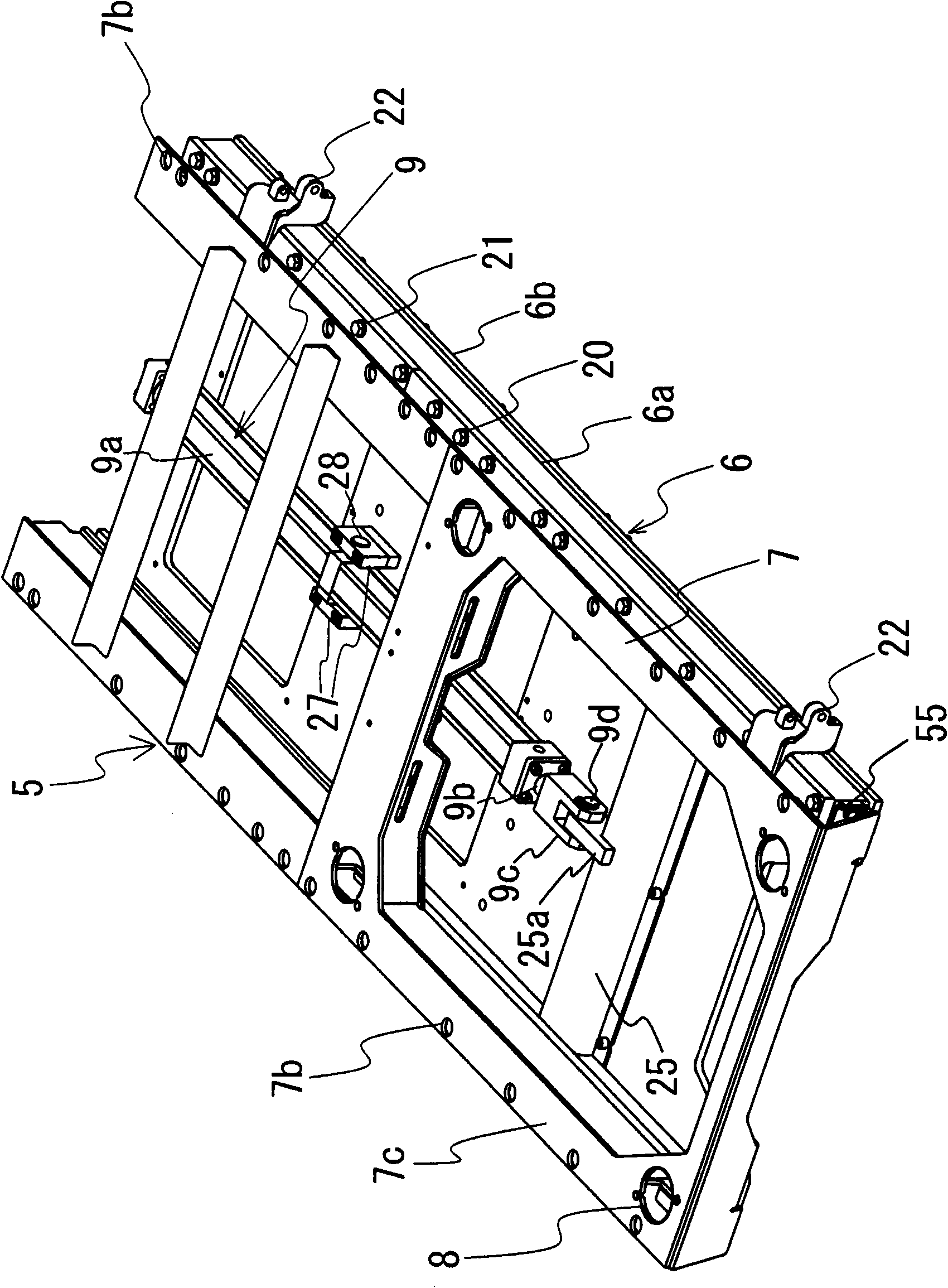

[0093] Such as figure 2 As shown in the plan view of , the revolving frame 4a constituting the upper revolving body 4 is provided with a bed 5 at the front of one side (the left side in the illustrated example). And, this bed 5 is made of the lower bed 6 fixed on the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com