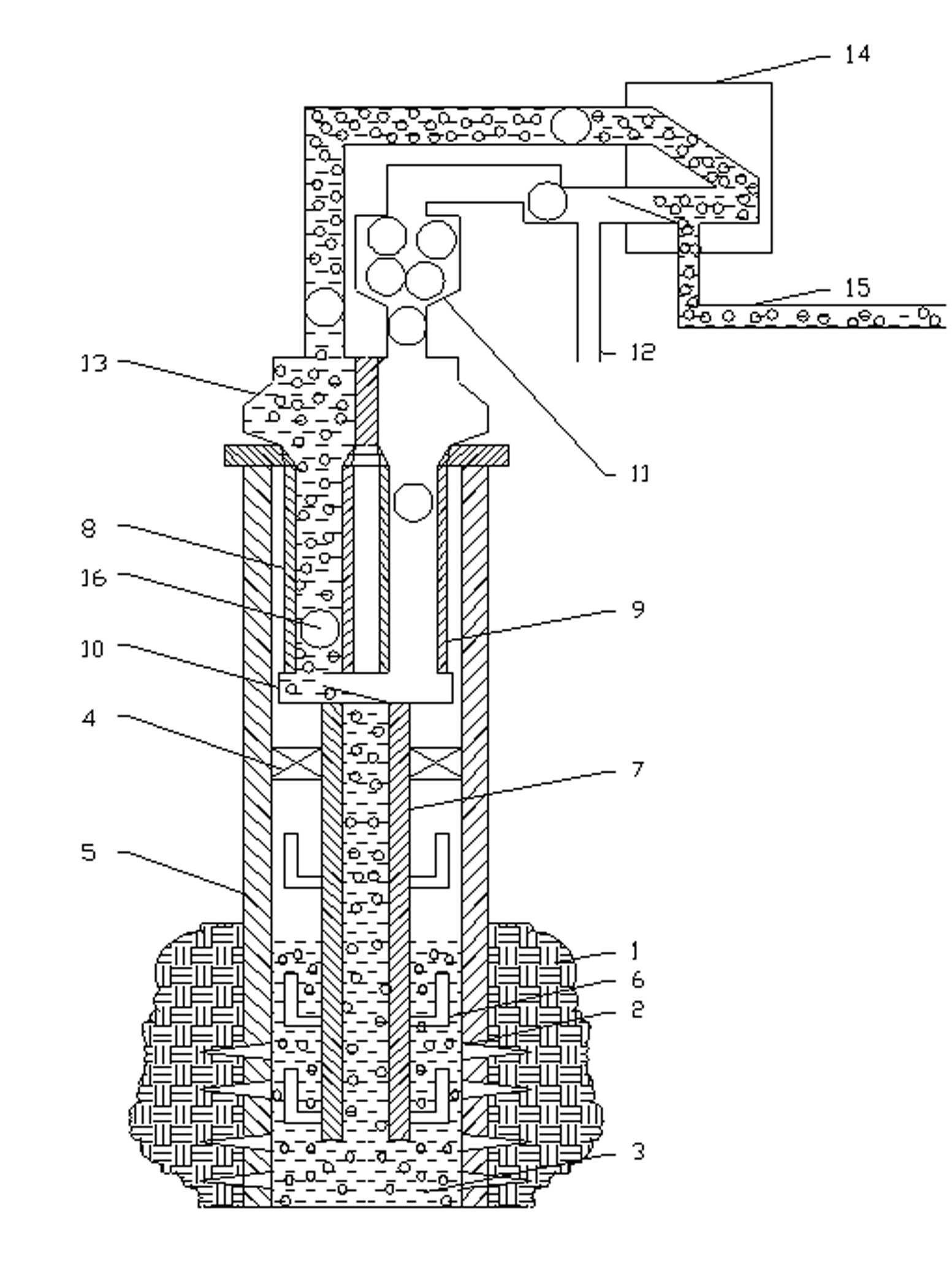

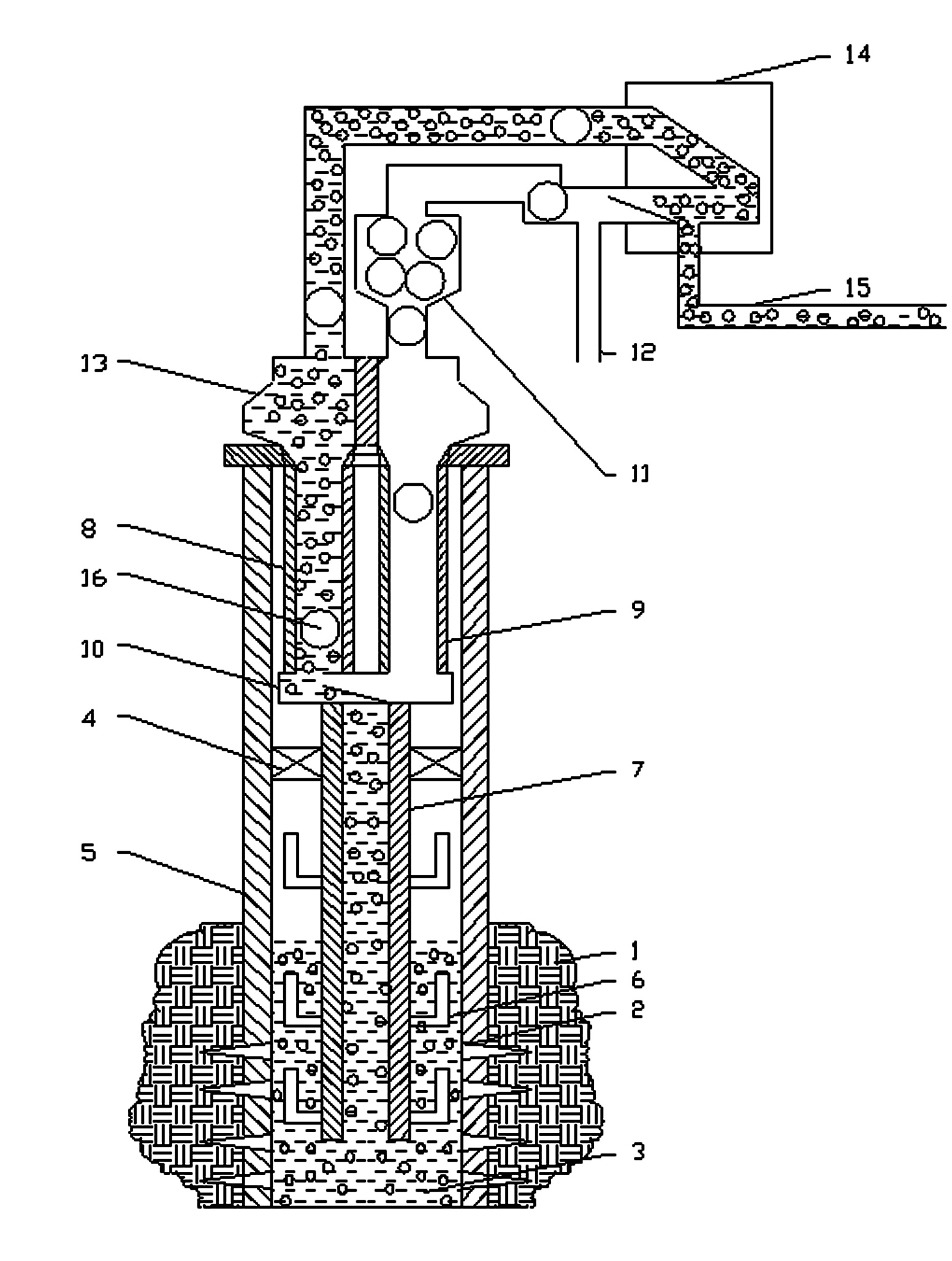

Gas lift method of combined ball plug for drainage and gas production of oil and gas well

A combined, ball-plug technology, applied in the production of fluids, earth-moving, wellbore/well components, etc., can solve the problems of limited running depth, poor economy, poor adaptability, and low system reliability, and achieve the structural principle. Simple, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] Bottomhole fluid accumulation occurs at the bottom of the gas well. Assuming that the main components of the liquid are water and oil, the density of the liquid is 800kg / m 3 , the acceleration due to gravity is 10m 2 / s, the rated working pressure of the ground compressor is 35Mpa, and the energy consumed by the damping force accounts for 20% of the output power. The specified rated working pressure is the maximum pressure required for the system to start. Theoretically the maximum descent depth is:

[0016] h 1 = P n x η / ρg =35×10 6 ×0.8 / 800 / 10=3500(m)

[0017] After applying the combined ball plug gas lift method, an independent chamber is formed between the bottom gas lift valve and the packer. As the gas pressure in the chamber increases, the gas lift valve is opened successively, and the gas enters the tubing, reducing the The density of the mixed liquid. Suppose the density of the liquid after mixing is 650kg / m 3 , keeping other parameters unchanged, for...

example 2

[0021] Bottomhole fluid accumulation occurs at the bottom of the gas well. Assuming that the main components of the liquid are water and oil, the density of the liquid is 800kg / m 3 , the acceleration due to gravity is 10m 2 / s, the energy consumed by the damping force accounts for 20% of the output power, and the dynamic liquid level of the effusion is 3000m, which requires the ball plug gas lift to be lowered at least at a depth of 3500m. For conventional ball plug gas lift, it is necessary to start the system The required pressure is at least:

[0022] P n1 = ρgh / η =800×10×3500 / 0.8=35(Mpa)

[0023] After applying the combined ball plug gas lift method, the gas enters the oil pipe through the gas lift valve to reduce the density of the mixed liquid, assuming that the density of the mixed liquid is 650kg / m 3 . The plunge depth of the ball plug air lift is required to be at least 3500m. For the combined ball plug air lift, the pressure required to start the system is at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com