Starting and operating protection system of solar cavity type heat absorber

A protection system and heat absorber technology, applied in lighting and heating equipment, steam boiler components, steam boiler accessories, etc., can solve the problems of superheater burning, water shortage, easily damaged boiling tubes, etc., to speed up the start-up speed , to ensure safety and save the effect of startup time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

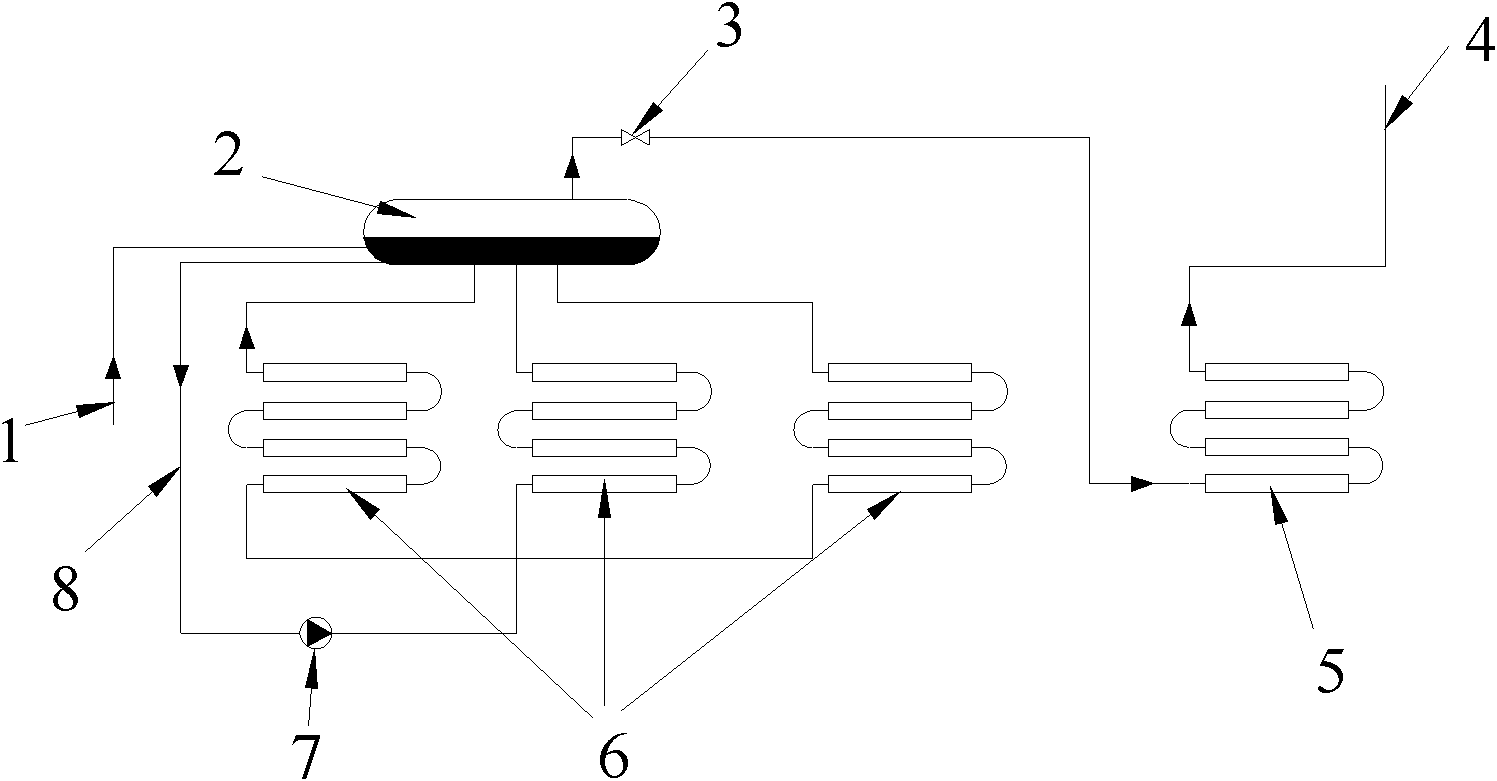

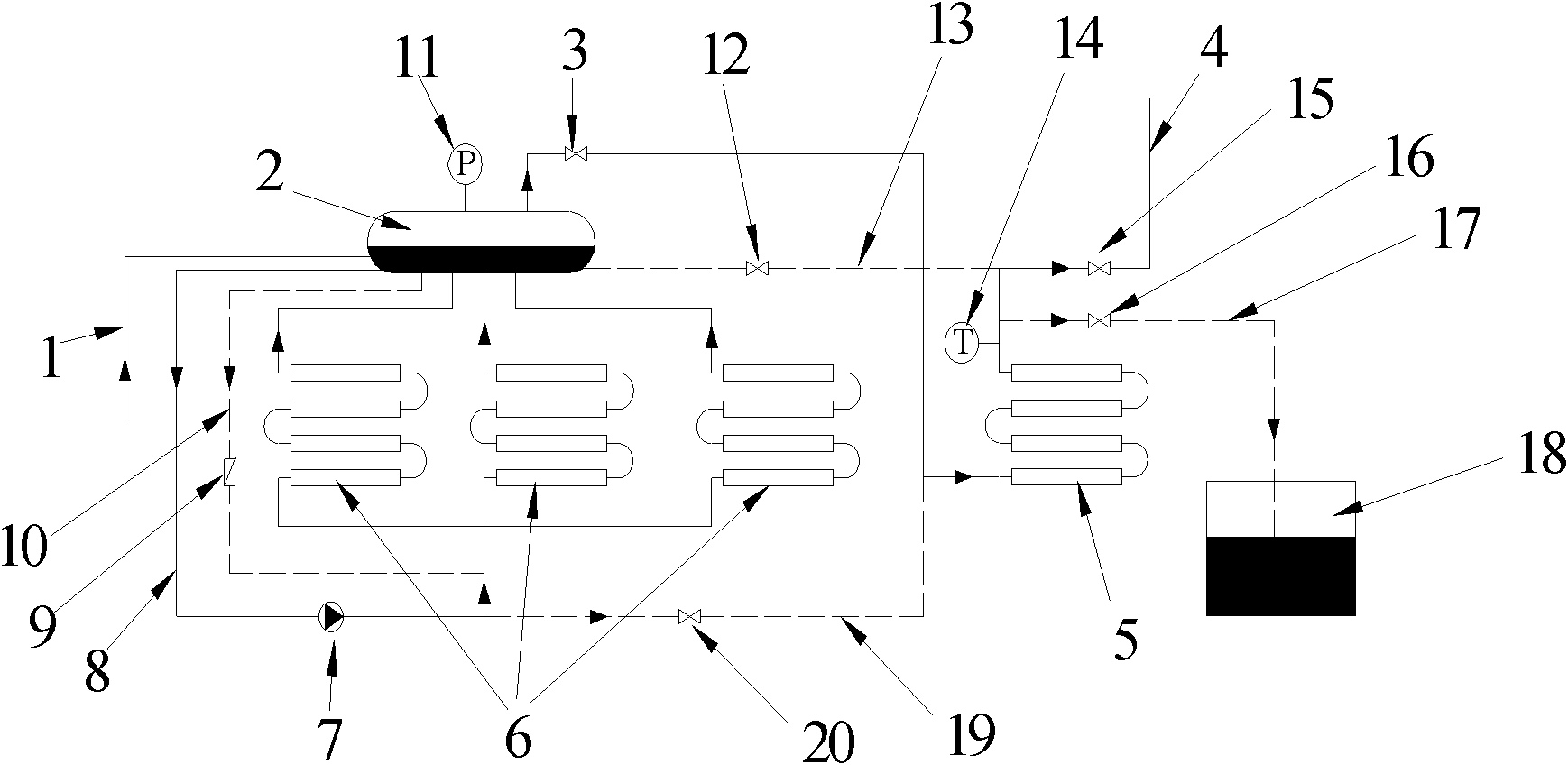

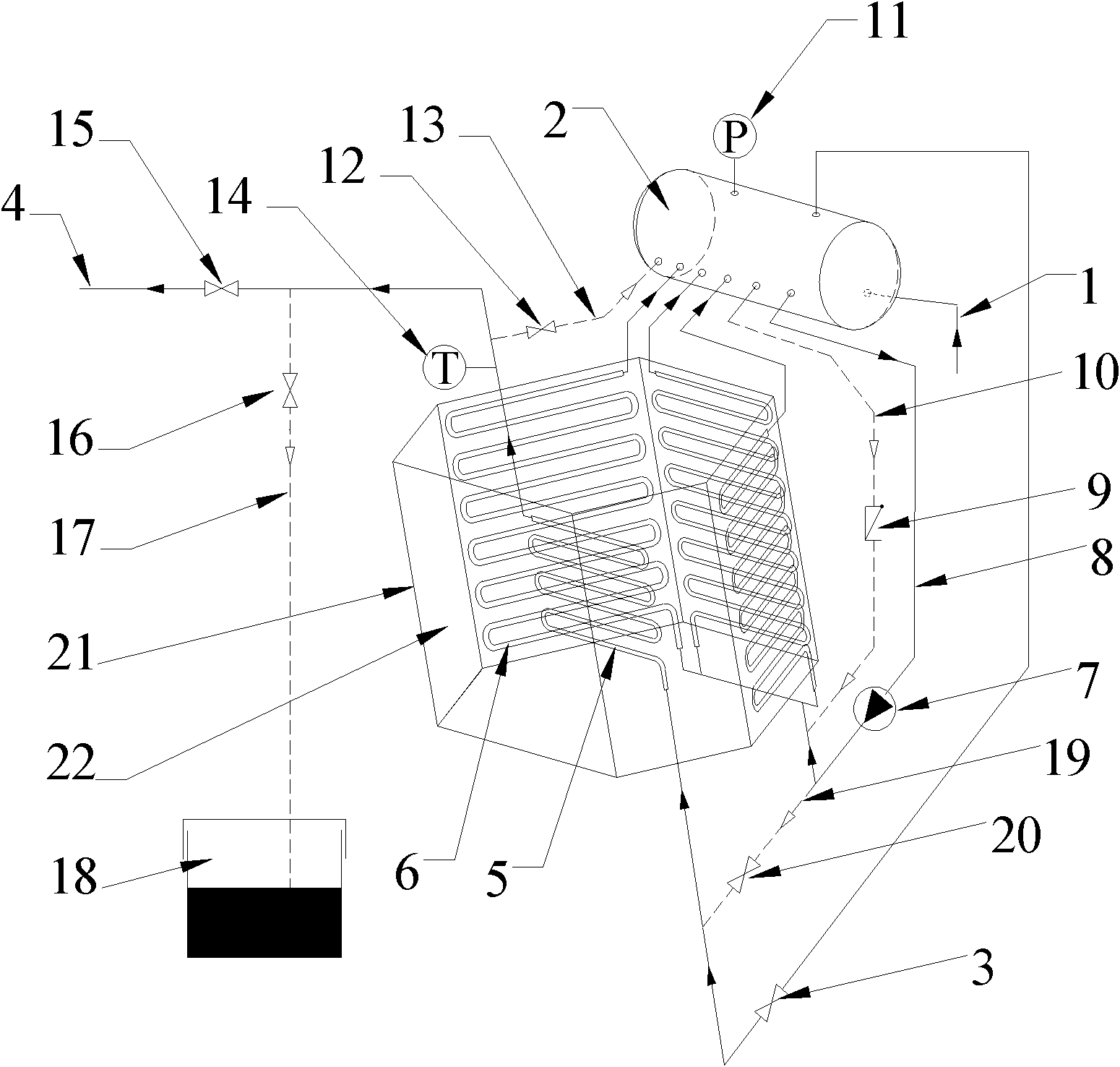

[0019] refer to figure 2 and image 3 , the protection system for the startup and operation of the solar cavity heat absorber of the present invention has two protection structures-the protection structure of the steam-water circulation in the pot of the cavity heat absorber and the protection structure of the superheater of the cavity heat absorber. figure 2 Shown in dotted line.

[0020] Wherein the first protection structure is the protection structure of the vapor-water circulation in the cavity heat absorber pot, which is combined by the downcomer 10 and the check valve 9 . Its specific structure is: a pipeline is connected in parallel next to the high-temperature circulation pump 7 of the steam-water circulation system in the pot of the cavity heat absorber, and the pipeline is directly connected to the drum 2 and the boiling tube 6 of the steam-water circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com