Refrigeration circulating system and application thereof

A circulating system and condenser technology, which is applied in refrigerators, refrigeration and liquefaction, and irreversible cycle compressors, etc., can solve the problems that the minimum capacity of the compressor cannot be reduced, and the maximum capacity cannot be increased, and achieves a simple and reasonable structure. Low-cost, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

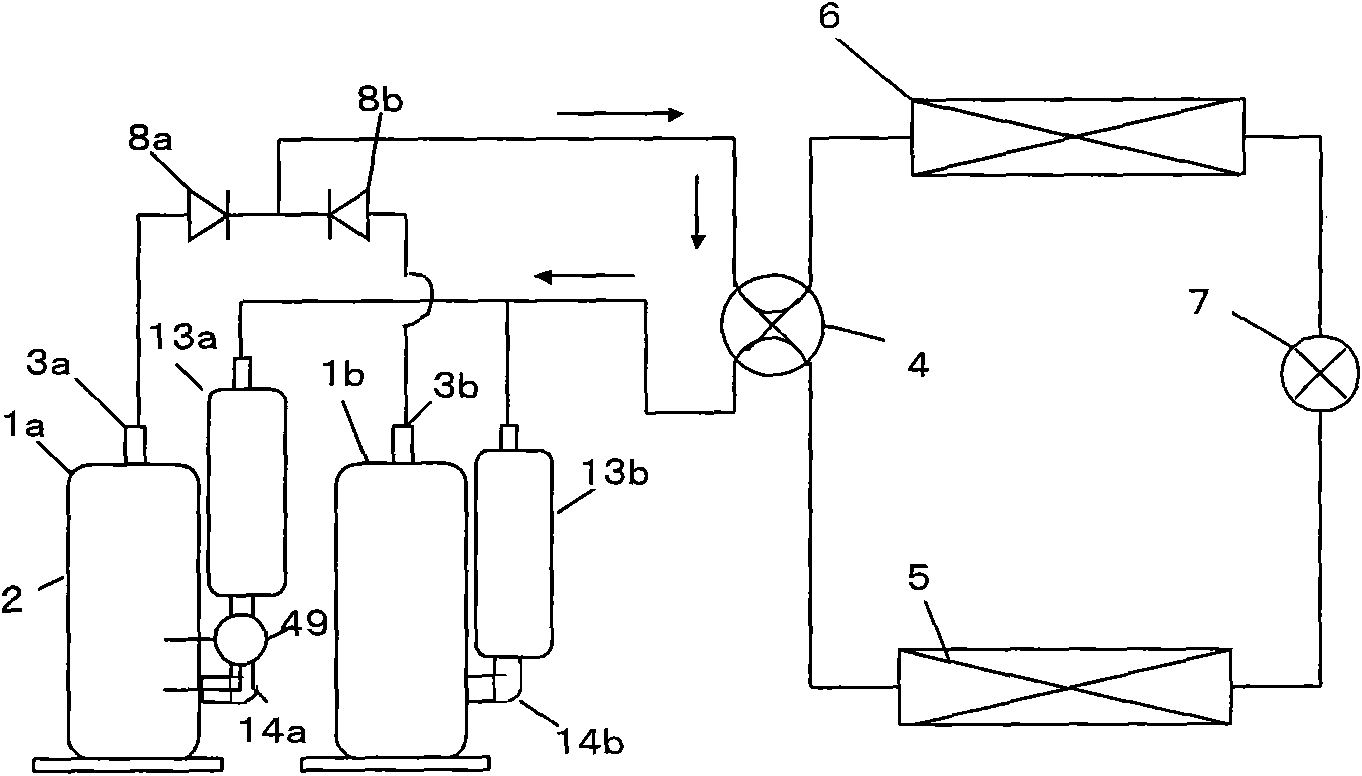

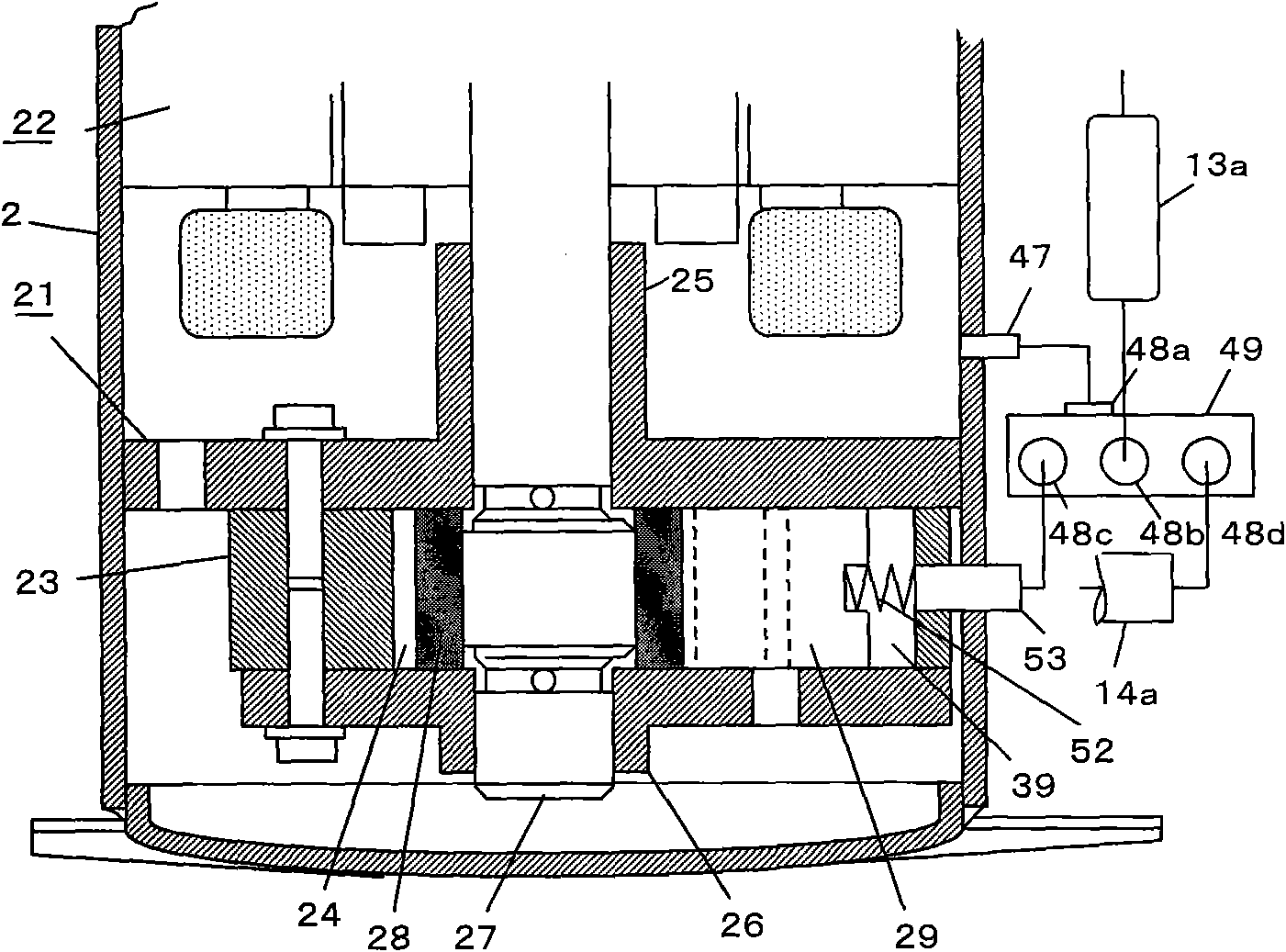

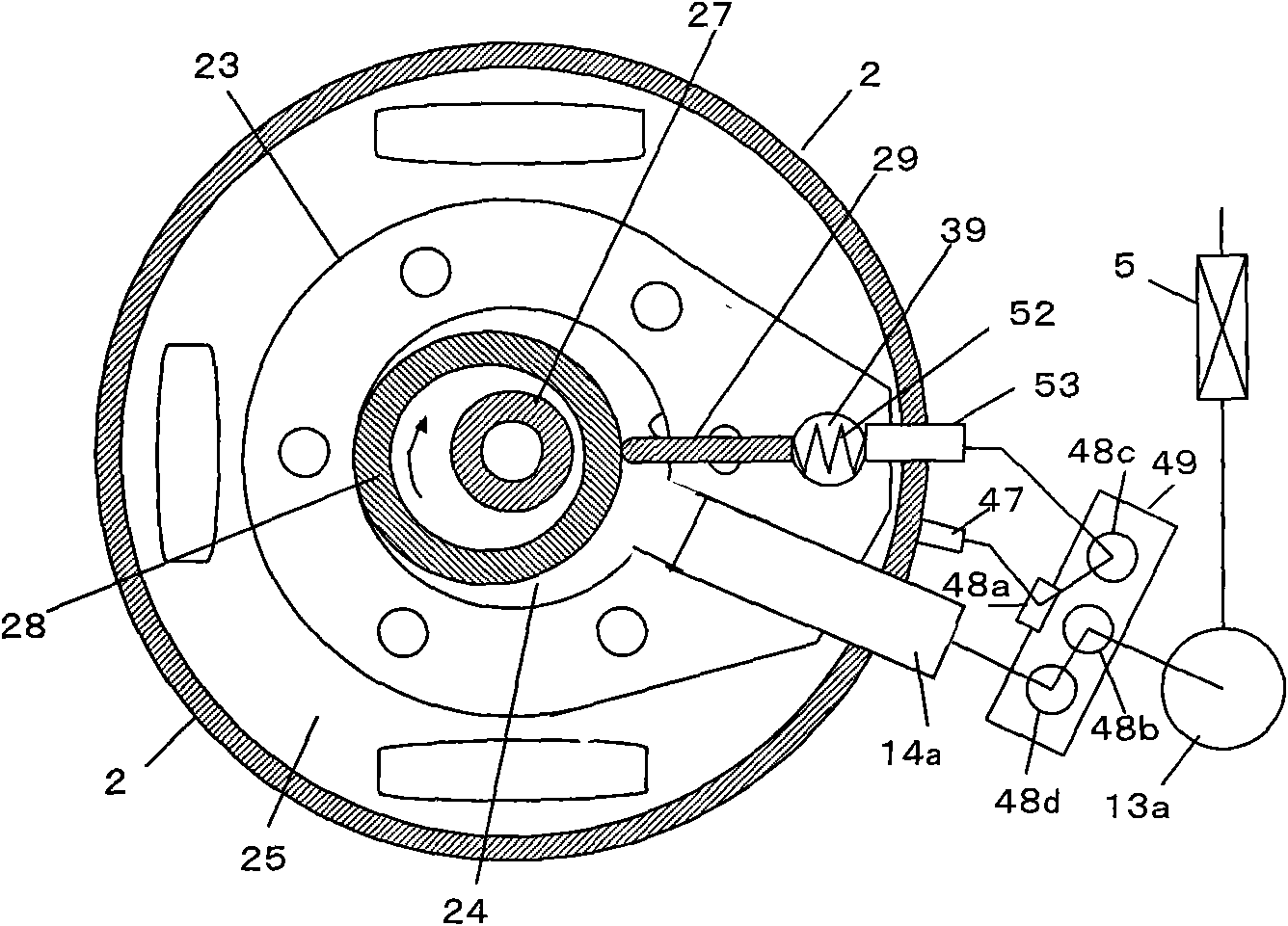

[0031] figure 1 A capacity-controlled single-cylinder type first rotary compressor 1a equipped with a variable cooling capacity through capacity control is shown, and a normal general fixed-capacity second rotary compressor that controls cooling capacity by continuation and stop of operation is shown. 1b refrigeration cycle.

[0032] In cooling mode, when both the first rotary compressor 1a and the second rotary compressor 1b are in operation, the refrigerant gas discharged from the first discharge pipe 3a and the second discharge pipe 3b of the two compressors passes through the The first check valve 8A and the second check valve 8b flow into the four-way switching valve 4, reach the outdoor heat exchanger 6, and become condensed refrigerant. Then, it passes through the expansion valve 7, evaporates in the indoor heat exchanger 5, and reaches the first liquid storage tank 13a and the second liquid storage tank 13b with respective compressors. Thereafter, the first suction p...

no. 2 example

[0059] In the second embodiment of the present invention, a capacity-controlled first rotary compressor and two fixed-capacity second and third rotary compressors without capacity control means are simultaneously mounted on an air conditioner or on the refrigeration system. results, such as Figure 7 As shown, compared with the first embodiment, the maximum value of the cooling capacity can be made larger. Moreover, like the first embodiment, the variable cooling capacity can be changed linearly and freely.

[0060] When the first rotary compressor, the second rotary compressor, and the third rotary compressor are simultaneously operated, this is called an A+B+C mode operation. As described above, by arbitrarily increasing the number of fixed-capacity rotary compressors, the number can be increased in a controllable manner while maintaining the cooling capacity variable means of the first embodiment.

[0061] Next, the gist of the invention will be described.

[0062] A si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com