Beverage bottle recycling machine

A beverage bottle and recycling machine technology, applied in the field of machine devices, can solve the problems of pollution on the outer packaging surface, multiple energy sources, and inability to carry out recycling and sorting work, and achieve the effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

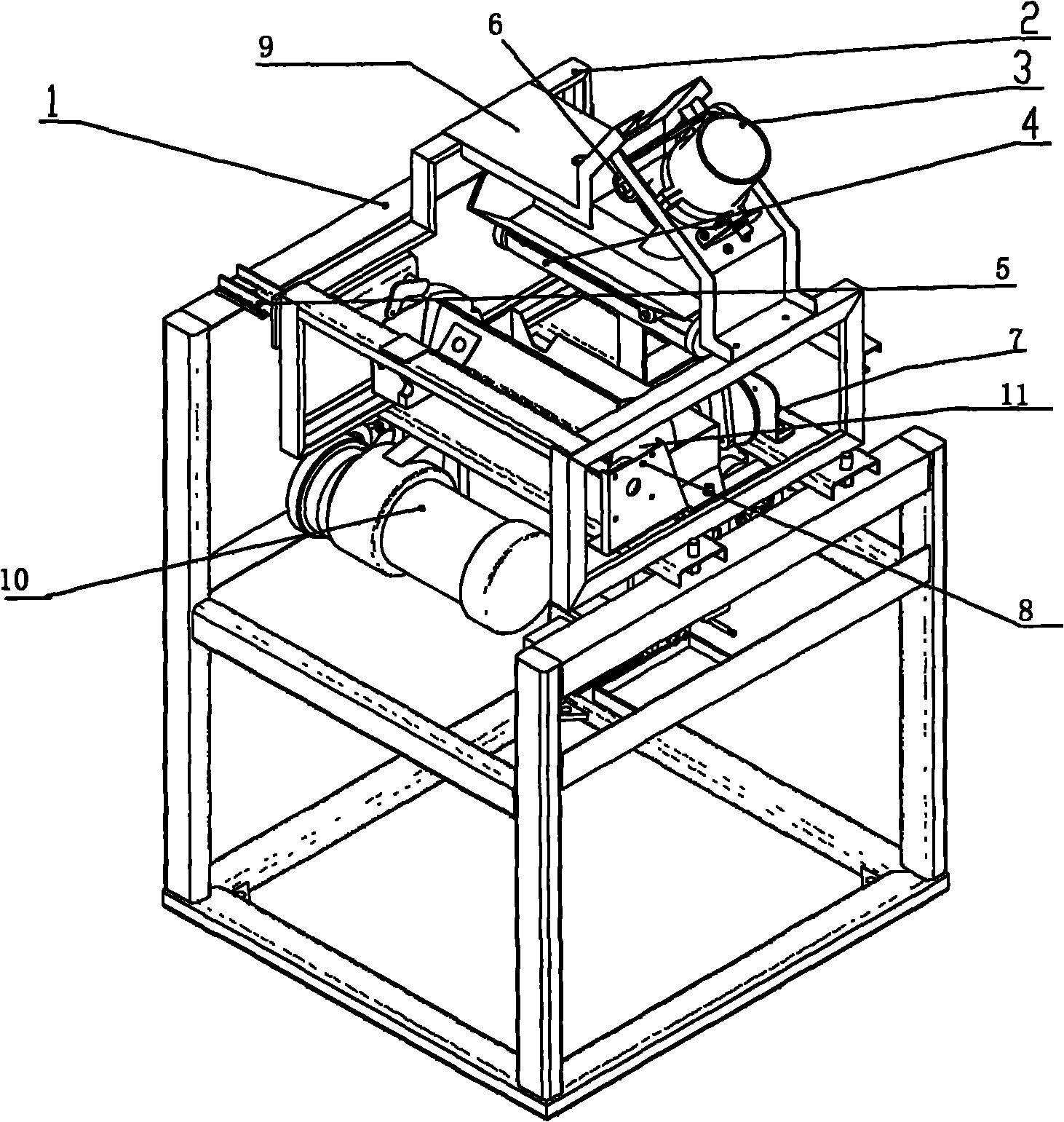

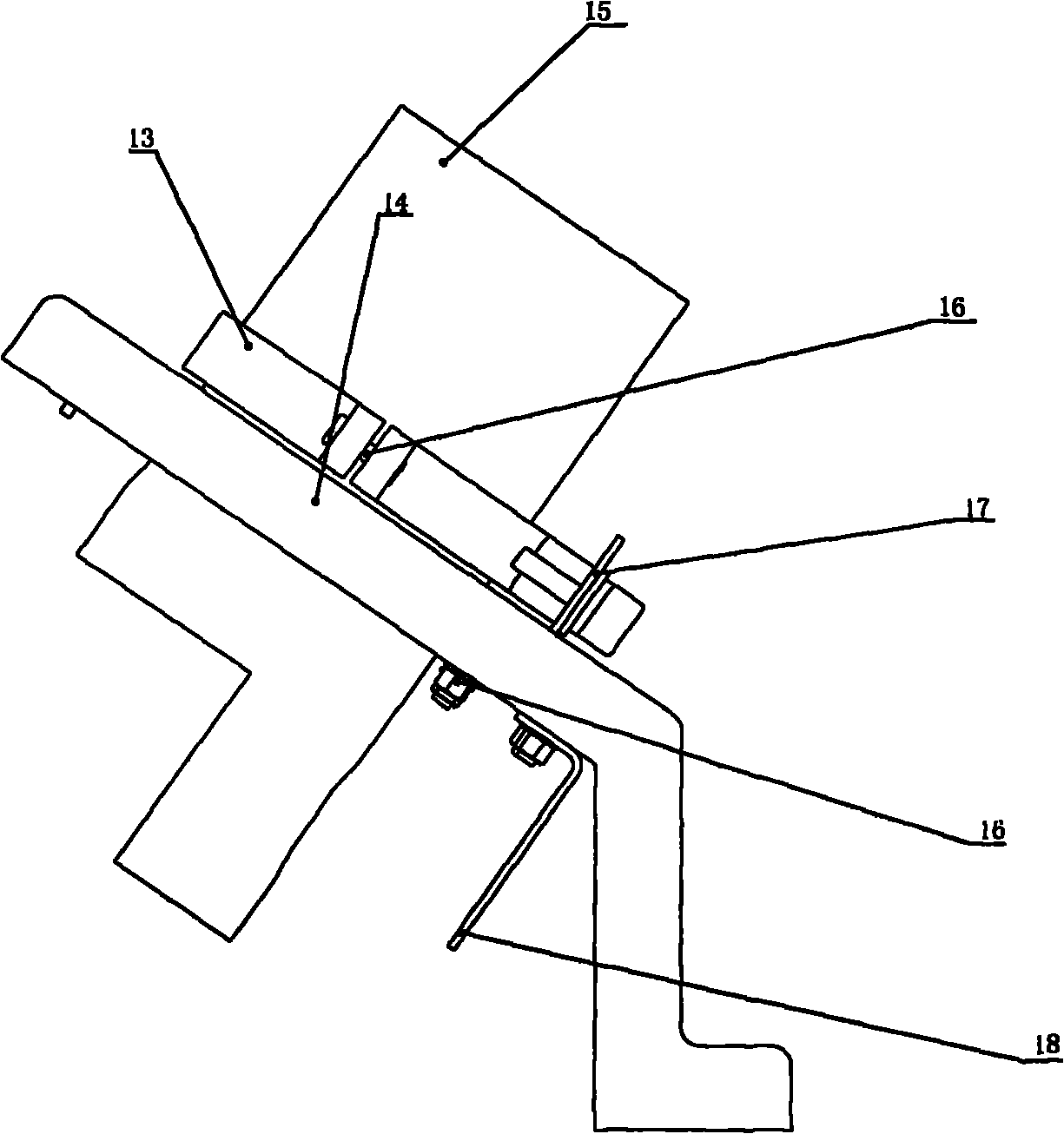

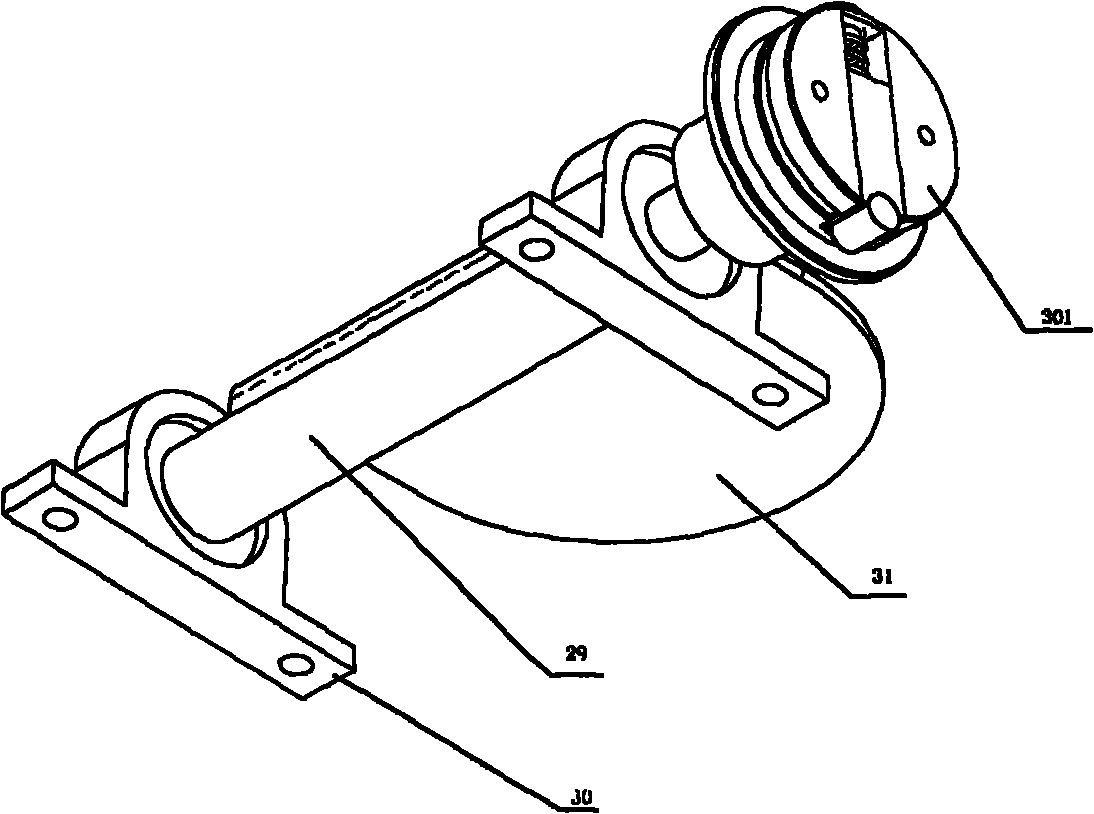

[0026] as the picture shows, Figure 1-7 It is one of the preferred modes of the embodiment of the present invention.

[0027] In the figure, beverage bottles and cans enter from the feed passage 15 and reach the bottom of the feed passage 15. There is a baffle plate 31 of the feed shaft assembly 6 at the bottom of the feed passage 15 to block the beverage bottles and cans. The metal detector on the side Identify the beverage bottles and cans. When the number of beverage bottles and cans collected by the collection box does not reach the set limit, the feed motor drives the feed limit shaft 29 welded to the material retaining plate 31 to rotate, and the material retaining plate rotates downward , leave a gap, the beverage bottle can falls in the material receiving box a28, and the gravity sensor at the bottom of the material receiving box a28 carries out the gravity judgment to the beverage bottle can. In gravity discrimination, the present invention has preferred example as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com