Current control method used for high-voltage transducer

A high-voltage inverter and current control technology, which is applied in the four-quadrant motor control, AC motor control, control system, etc., can solve the problems of low-frequency operation torque ripple, high-frequency operation torque mutation, and affecting the mechanical life of the motor, etc. , to achieve stable and accurate detection of current, smooth and stable torque changes, and accurate and reliable detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

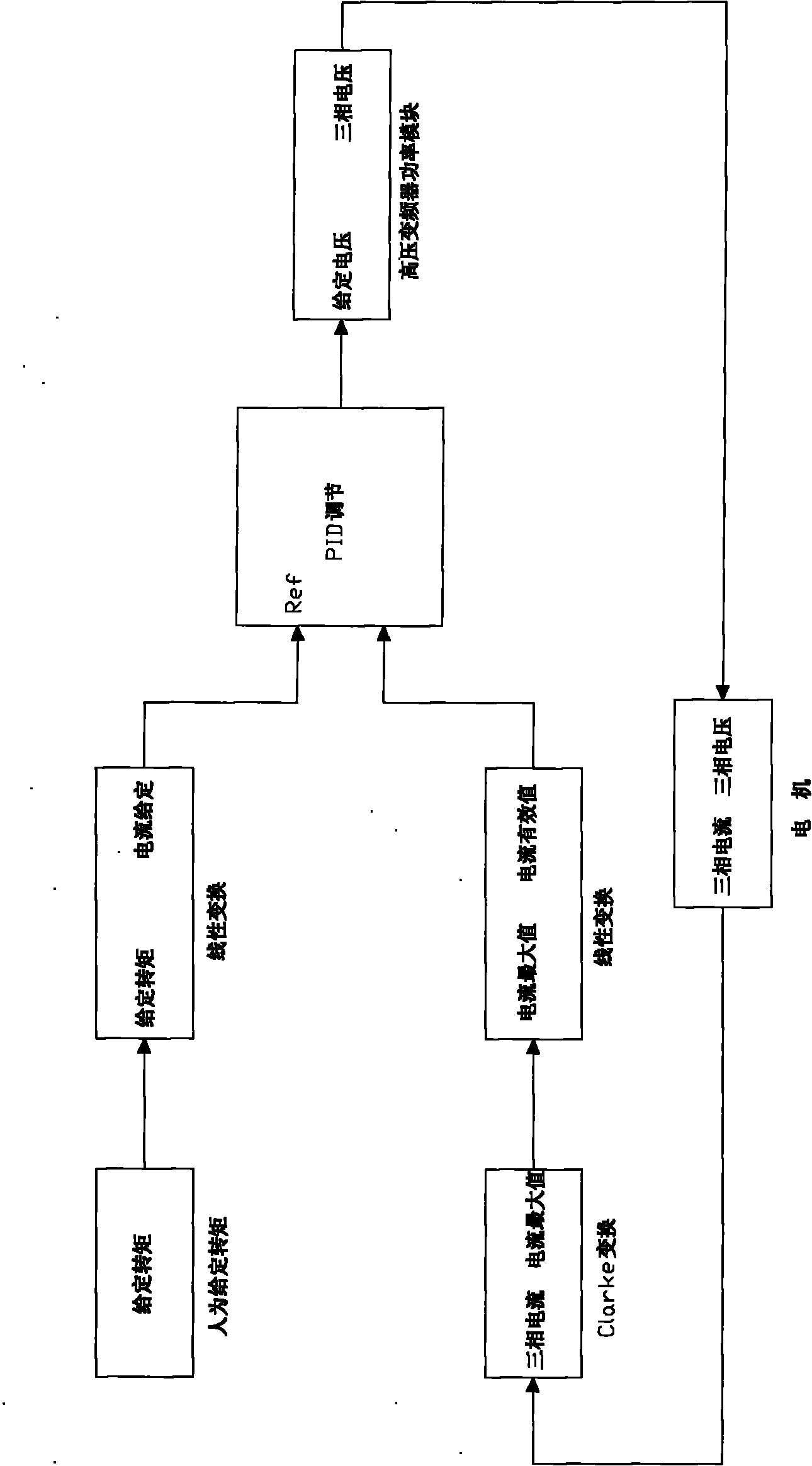

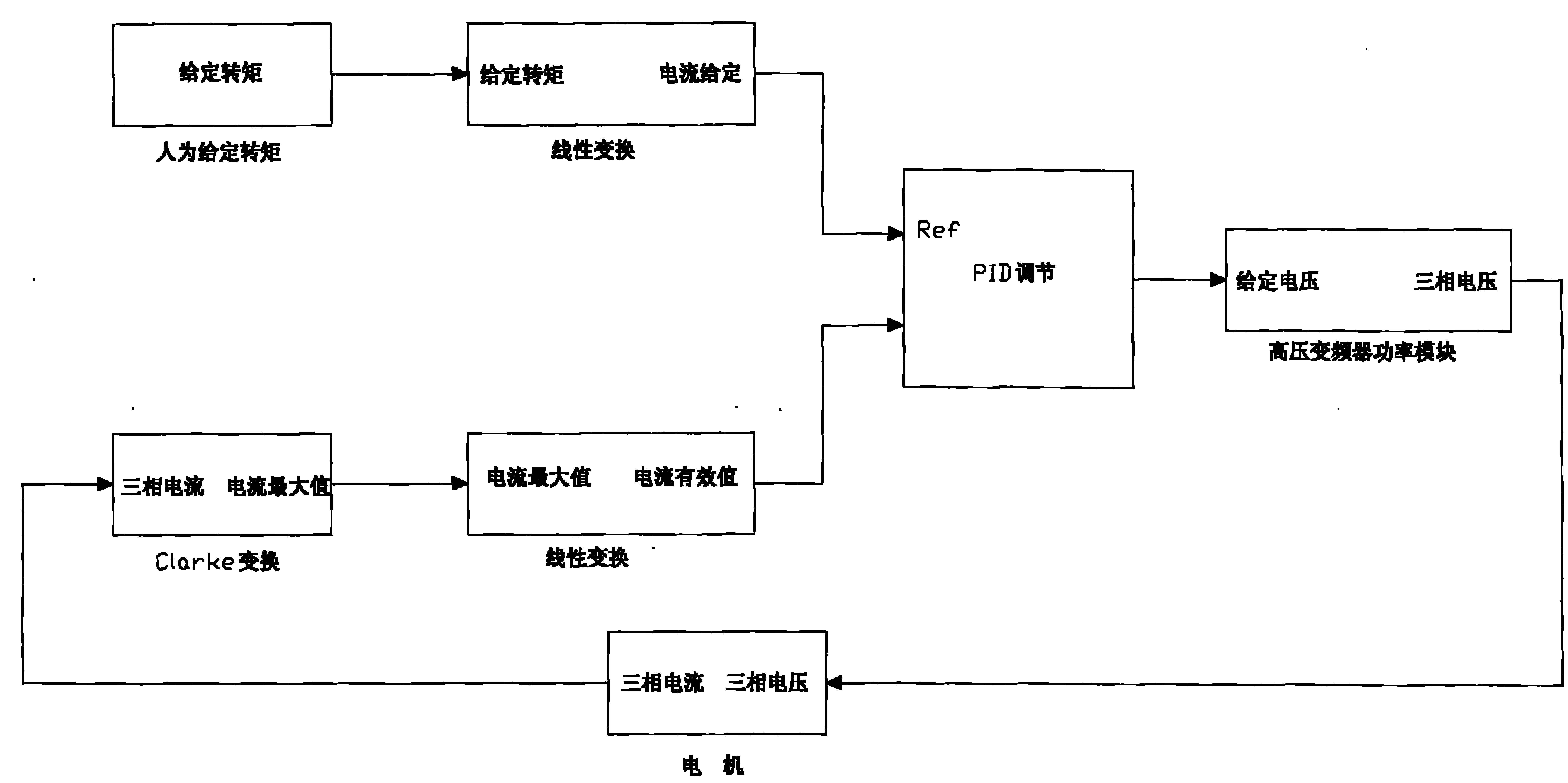

[0039] A current control method for high-voltage frequency converters, which uses the Clarke transformation principle to obtain accurate instantaneous current effective values, and changes the output voltage of the high-voltage frequency converter by changing the PWM working state of the power unit to automatically adjust the output current of the motor , quickly and stably control the motor output torque.

[0040] The method of calculating the instantaneous current RMS value through the principle of Clarke transformation is:

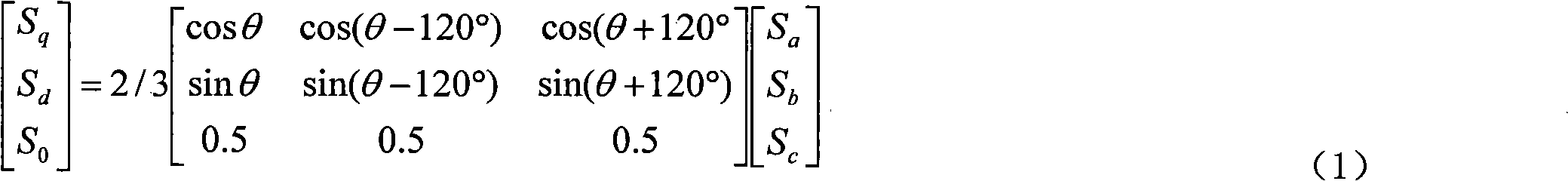

[0041] Let S be the variable to be transformed, then the transformation relationship from three-phase coordinates to two-phase coordinates is established as follows:

[0042]

[0043] Among them, S 0 is the zero-sequence component and can be ignored.

[0044] Let θ=0, then the q-axis and the a-axis coincide; ignoring the zero-sequence component, the formula (1) is simplified as

[0045] S q = ...

Embodiment 2

[0063] The method of calculating the effective value of the instantaneous current by the principle of Clarke transformation in Embodiment 1 can also be used to detect the effective value of the current of the fans and pumps driven by the high-voltage frequency converter.

[0064]In the past, the current RMS detection method is to perform root-mean-square processing on the sampled value of one cycle, and the calculated current RMS will lag behind one cycle, and the real-time performance is poor, and the current control is not ideal.

[0065] The invention adopts the principle of clarke transformation, only needs to obtain the real-time three-phase current from the sensor, can calculate the effective value of the instantaneous current, and realize the instantaneous detection of the current. Therefore, the problems of slow current detection and unsatisfactory current control are solved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com