Dust dumping structure for dust-collecting bucket

A technology of dust collection bucket and bucket body, which is applied in the direction of suction filter, etc., which can solve the problems affecting customer satisfaction, inconvenient operation, and rising dust, and achieve the effect of preventing dust splashing, improving satisfaction, and simple locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

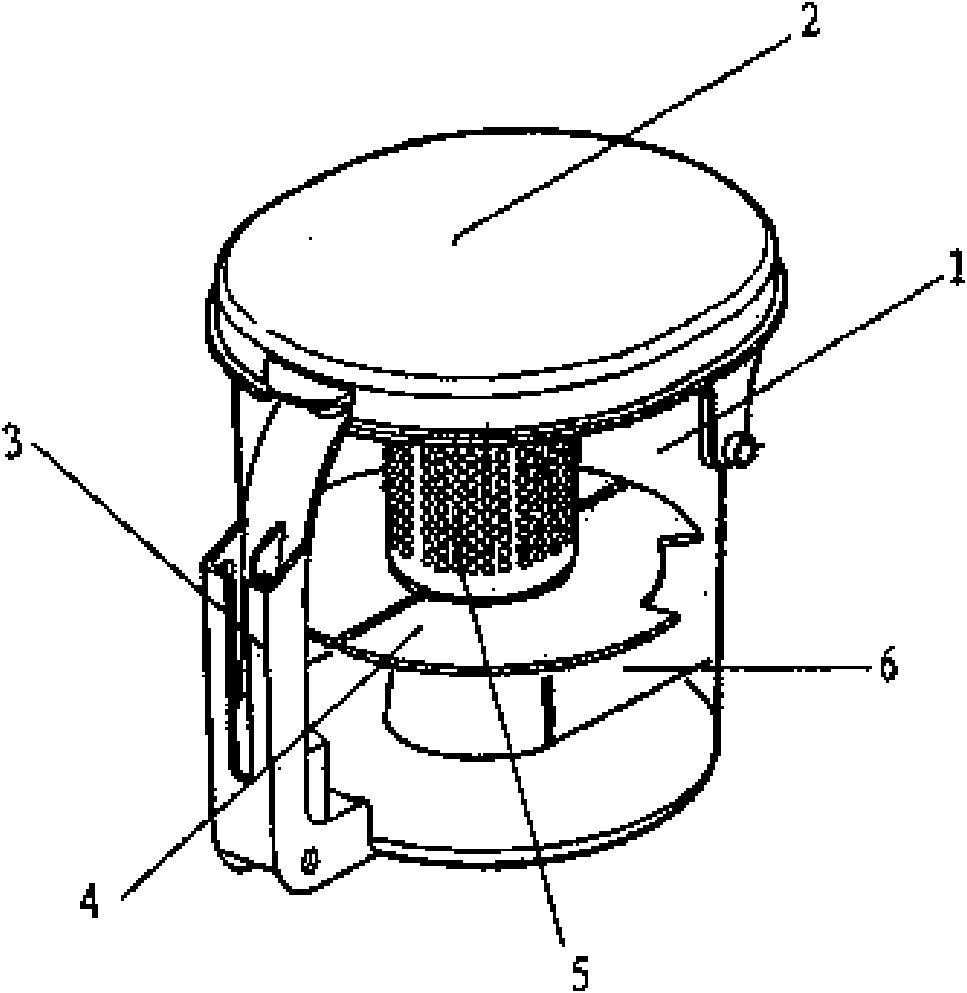

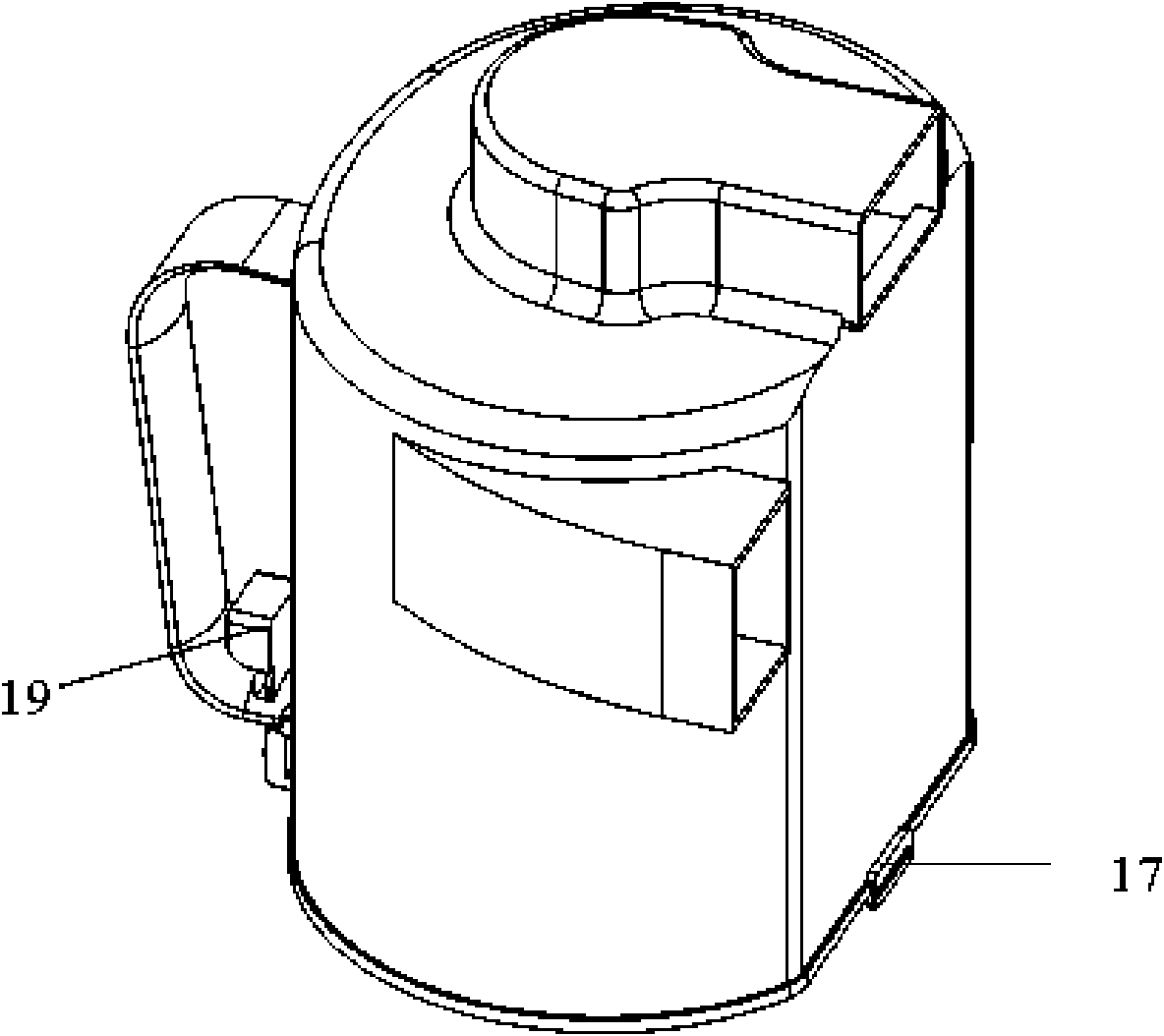

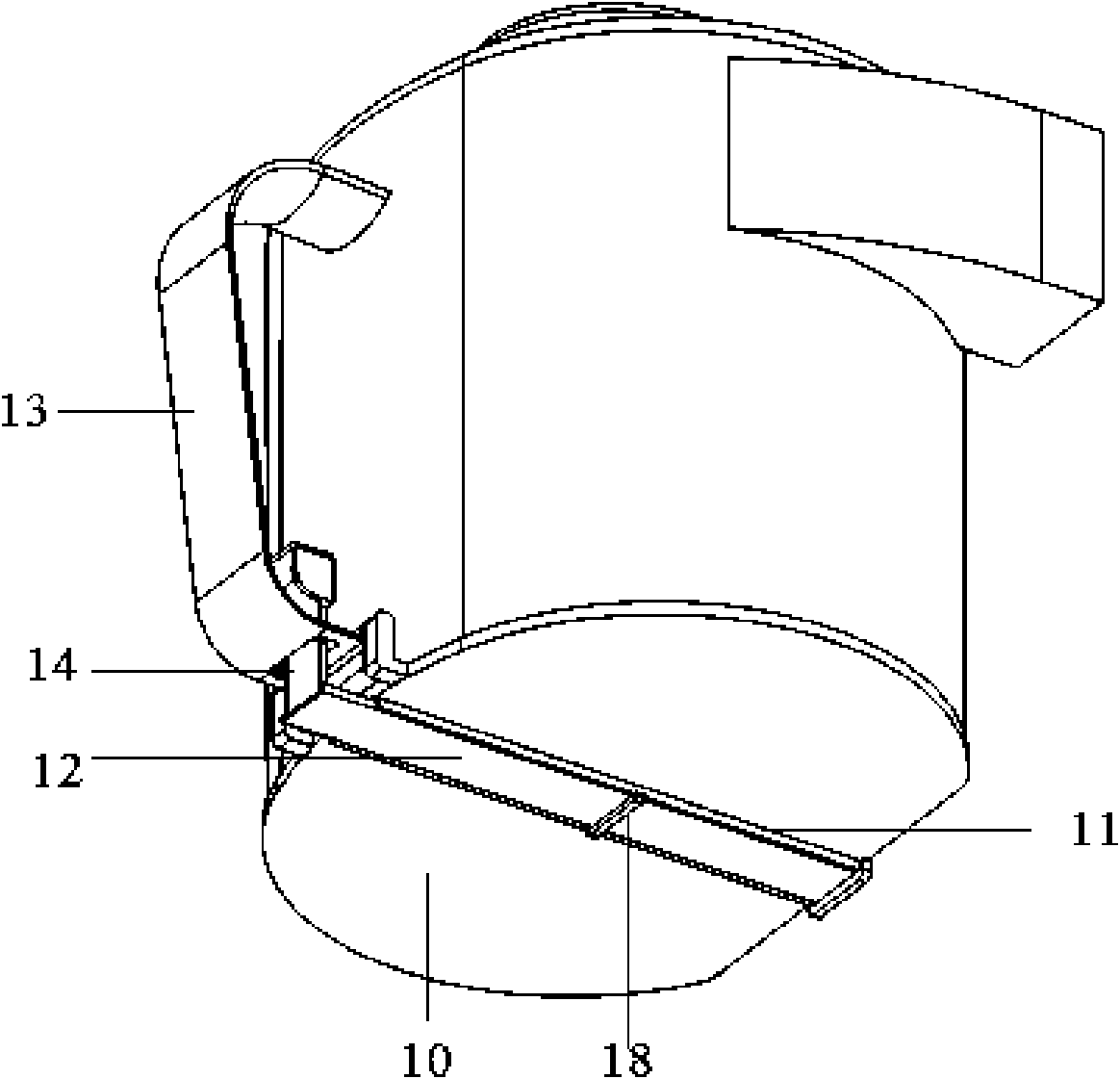

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0030] The working principle of the vacuum cleaner of the present invention is the same as that of the prior art, and the prior art can be referred to, so it will not be described again, and the same symbols as those of the prior art will be used. The differences between the present invention and the prior art will be described below Detailed explanation:

[0031] First, the first embodiment of the present invention will be described in conjunction with FIG. 25. A rectangular through hole is formed through the lower part of the handle 13, and groove slides 15 are formed on the inner side walls of the through hole, through which the brake arm 14 of the button 19 passes. The tongue 16 correspondingly formed on both sides of the brake arm 14 is slidably fixed in the groove slideway 15, and the groove slides to cooperate with the tongue so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com