Reverse-flow type cooling vibrating screen

A technology of countercurrent cooling and vibrating screen, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of high manufacturing and use costs, no reasonable combination, complex structure, etc., and achieve low manufacturing and use costs, simple and reliable structure , the effect of a reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

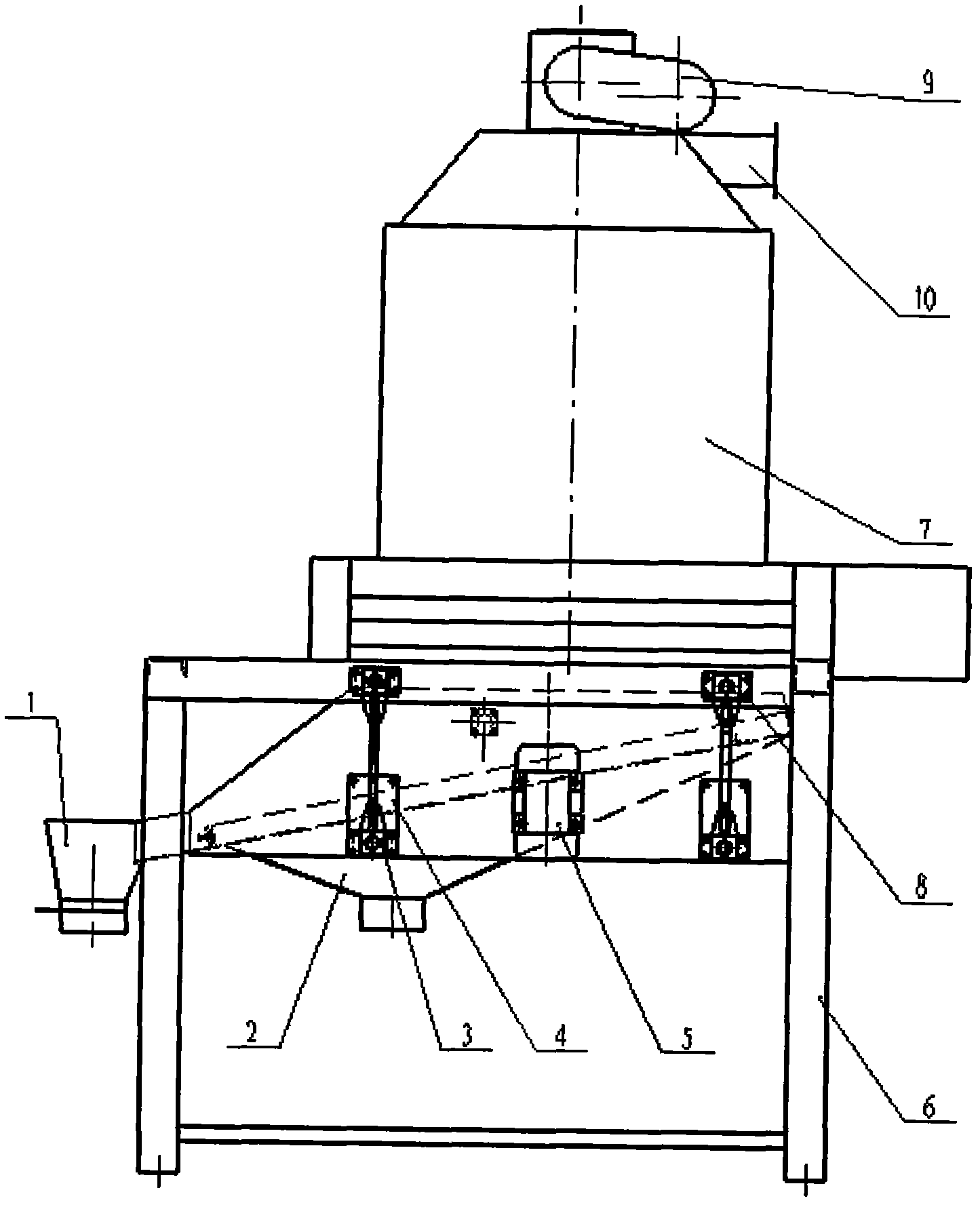

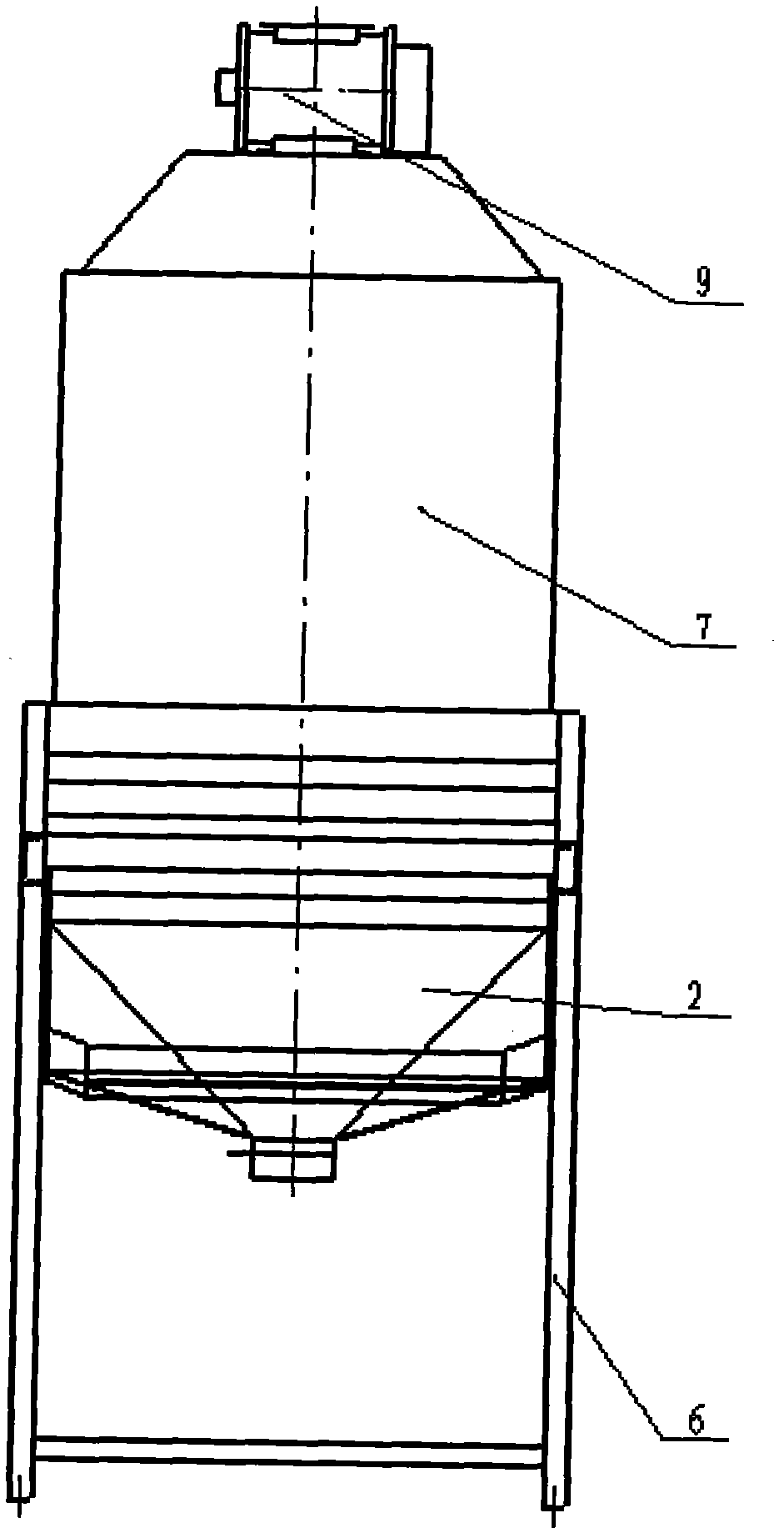

[0020] combine figure 1 and figure 2 , The counter-flow cooling vibrating screen proposed by the present invention includes a material locker 9, a counter-flow cooler 7, a sieve boat 2, a vibration motor 5, a suspension support 3, a bracket 6 and a hopper 1. Wherein, the feeding air locker 9 is installed on the top cover of the counterflow cooler 7 . Counterflow coolers 7 are respectively fixed on the left and right sides of the sieve ship 2 . The discharge hopper 1 is fixed on the front end of the support 6 by bolts. Further, a cooling air outlet 10 is fixed on the upper right side of the top cover of the counterflow cooler 7, and is connected to a fan (not shown) through an air duct.

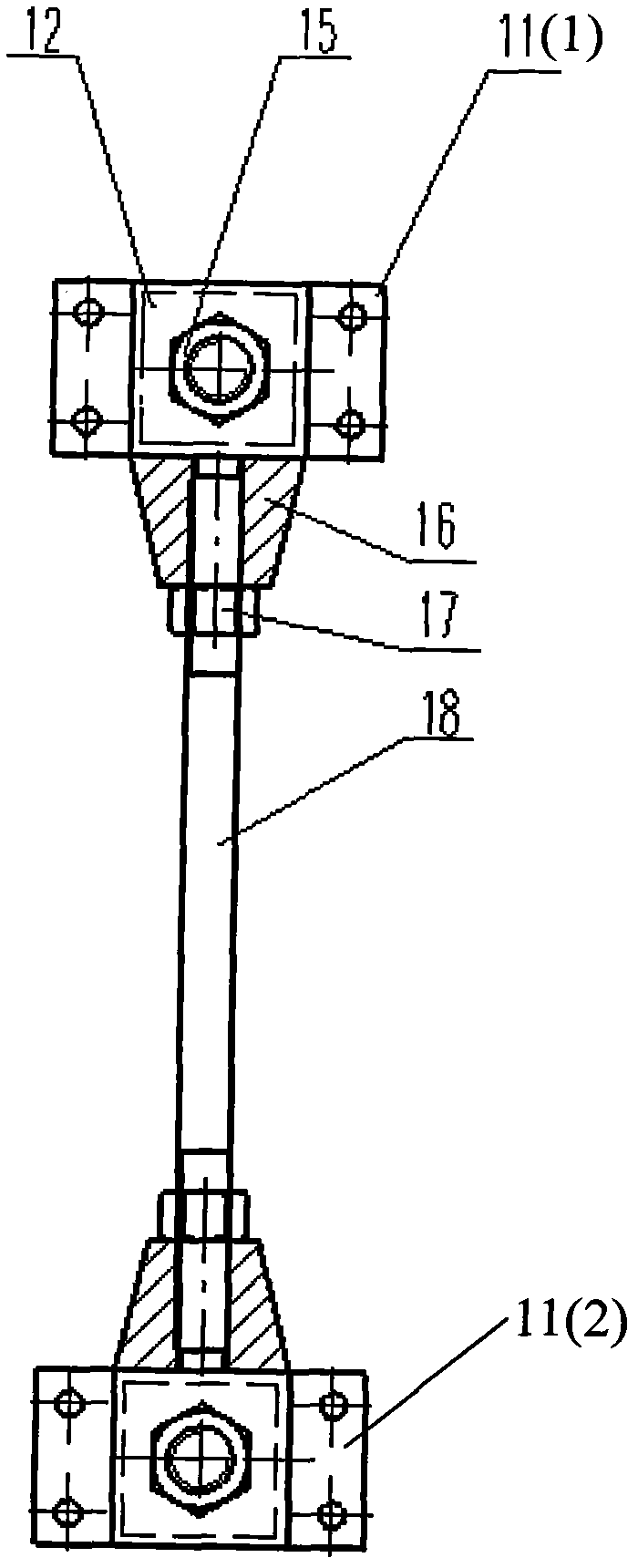

[0021] combine image 3 and Figure 4 , the suspension support 3 mainly includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com