Zero-point calibration method for hot continuous rolling machine frame

A zero-point calibration and frame technology, which is applied in the field of steel rolling, can solve problems such as inconsistent thickness difference, poor leveling effect, deviation of steel plate, etc., and achieve the effect of ensuring a balanced state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following describes in detail in combination with an embodiment.

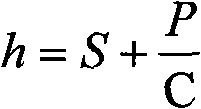

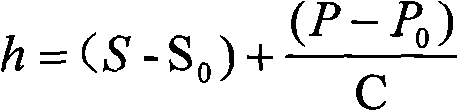

[0028] Take the last stand of hot continuous rolling as an example, an oil cylinder with a stroke of 30 millimeters is installed on the stand, and under normal rolling state, the working stroke of the oil cylinder is between 5 millimeters and 20 millimeters. Since the thickness range of the rolled steel plate at the end stand is basically between 2 mm and 10 mm, when the height of the oil column in the oil cylinder is 10 mm, the roll gap should be within the range of 10 mm (here set to 5 mm). The given zero-point calibration force F0 is 500 tons on each side of the roll, the balance calibration force F1 is 100 tons on each side of the roll and the roll is crawled at a speed of 20 revolutions per minute.

[0029] The first step: through the general method of moving the frame and electrically pressing down or changing the step pad, the current roll gap of the roll is smaller than the maximum extension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com