Automatic repeating poking mechanism

A burst, automatic technology, applied in nailing tools, manufacturing tools, etc., can solve the problems of automatic burst ricochet, automatic burst magazine easy to jam, etc., to avoid ricochet, avoid automatic burst jam phenomenon , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

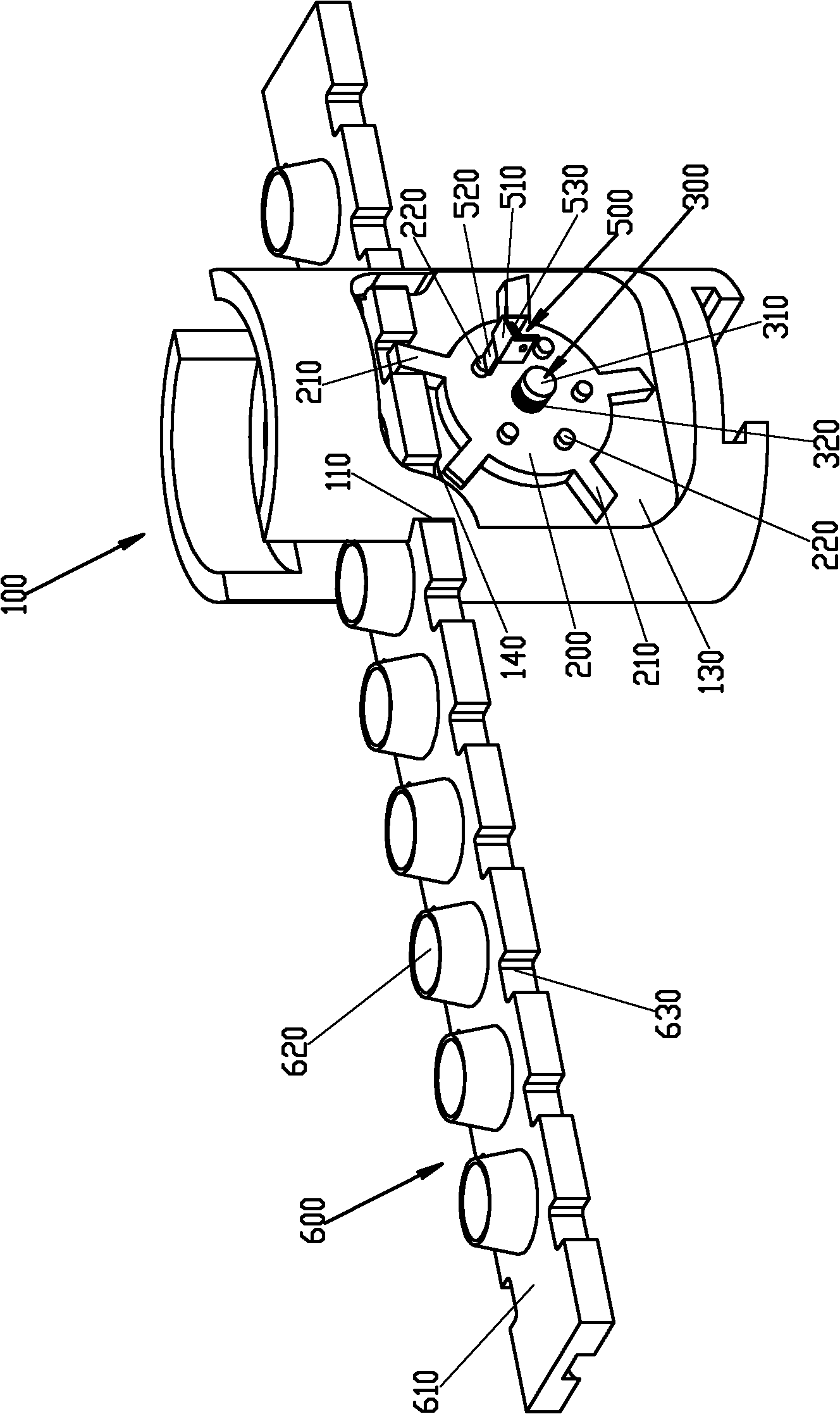

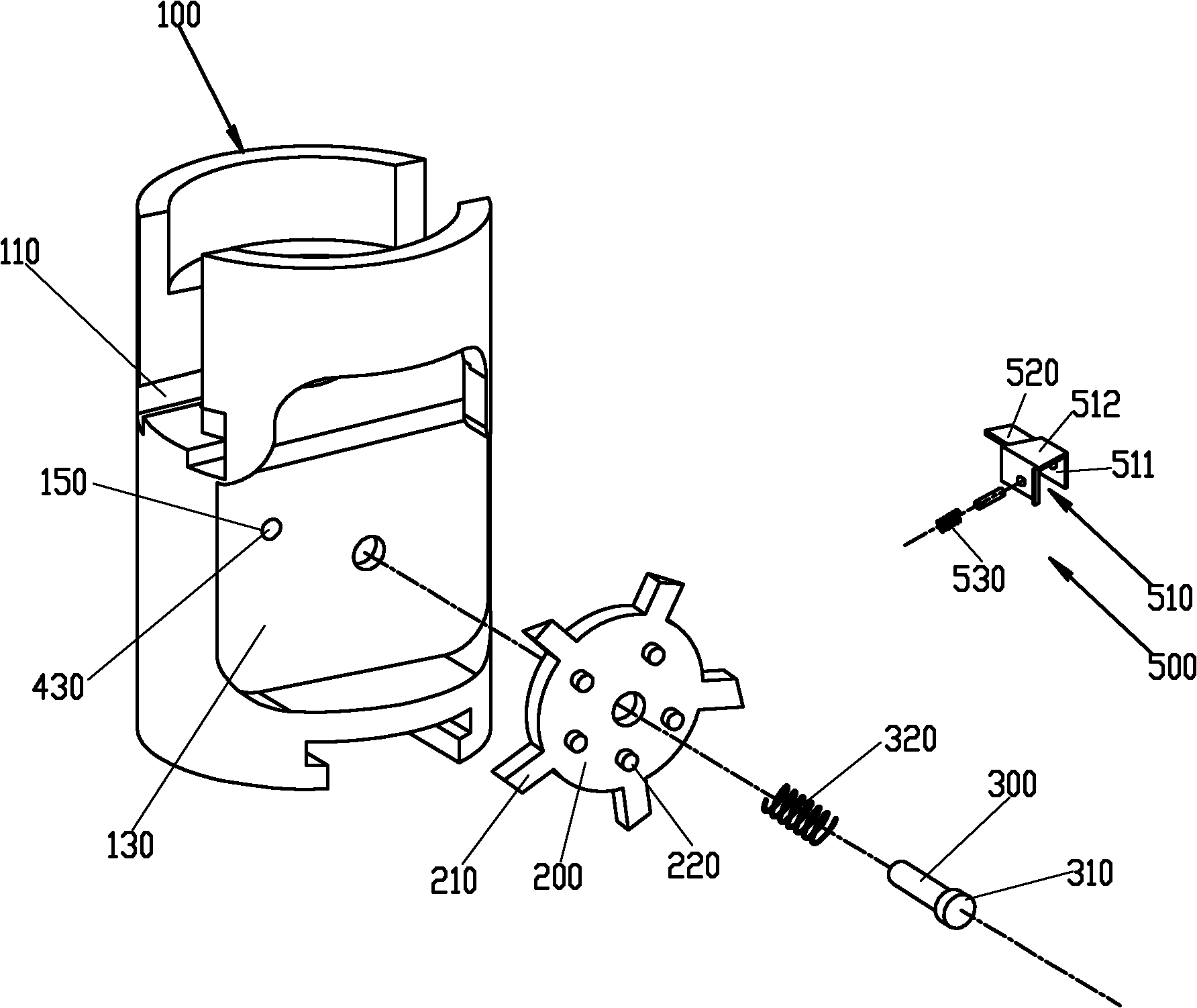

[0034] Please refer to the diagram Figure 1 to Figure 7 , an automatic continuous firing mechanism, which is attached to the cylindrical barrel 700 of the nail shooter (please refer to Figure 7 ), it includes a striker seat 100, a dial 200, a positioning shaft 300, an abutment mechanism 400 and an abutment mechanism 500.

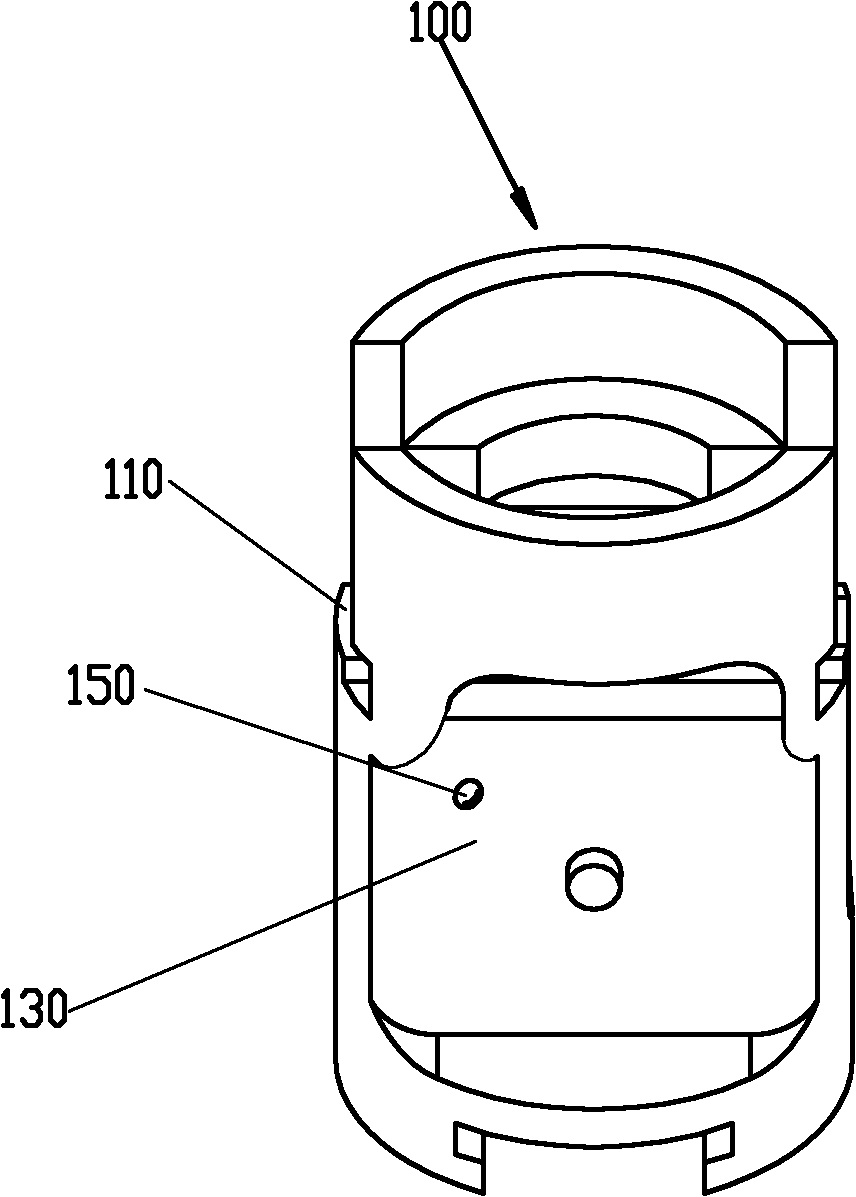

[0035] The firing pin seat 100 is set in a cylindrical shape, and the front surface of the firing pin seat 100 is provided with a sliding magazine groove 110 for the magazine 600 to slide through. Groove 110 and vertically slide the firing pin hole of the magazine groove 110. The cylindrical surface part of the firing pin seat 100 is recessed to form a positioning surface 130 parallel to the sliding direction of the sliding magazine groove 110. The positioning surface 130 and the sliding There is a connection slot 140 between the moving magazine grooves 110 . The firing pin base 100 defines a through mounting groove 150 , the front opening of which is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com