Antiskid lane

A technology of skid lanes and lanes, which is applied in the field of operation and transportation, can solve the problems of easy damage and difficult repair of anti-skid lanes, and achieve the effect of good impact resistance, hard damage and easy repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in combination with specific examples and with reference to the accompanying drawings.

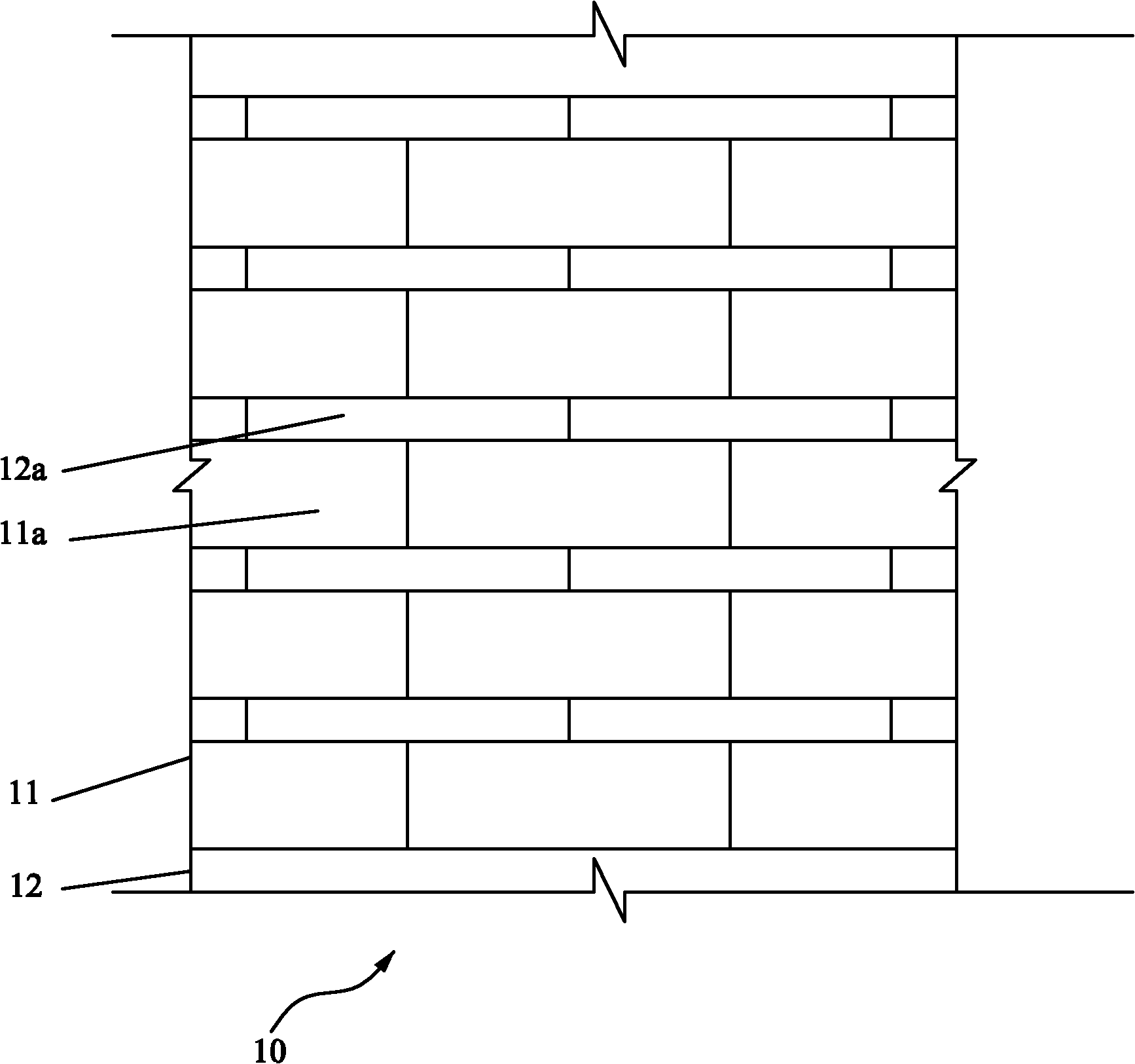

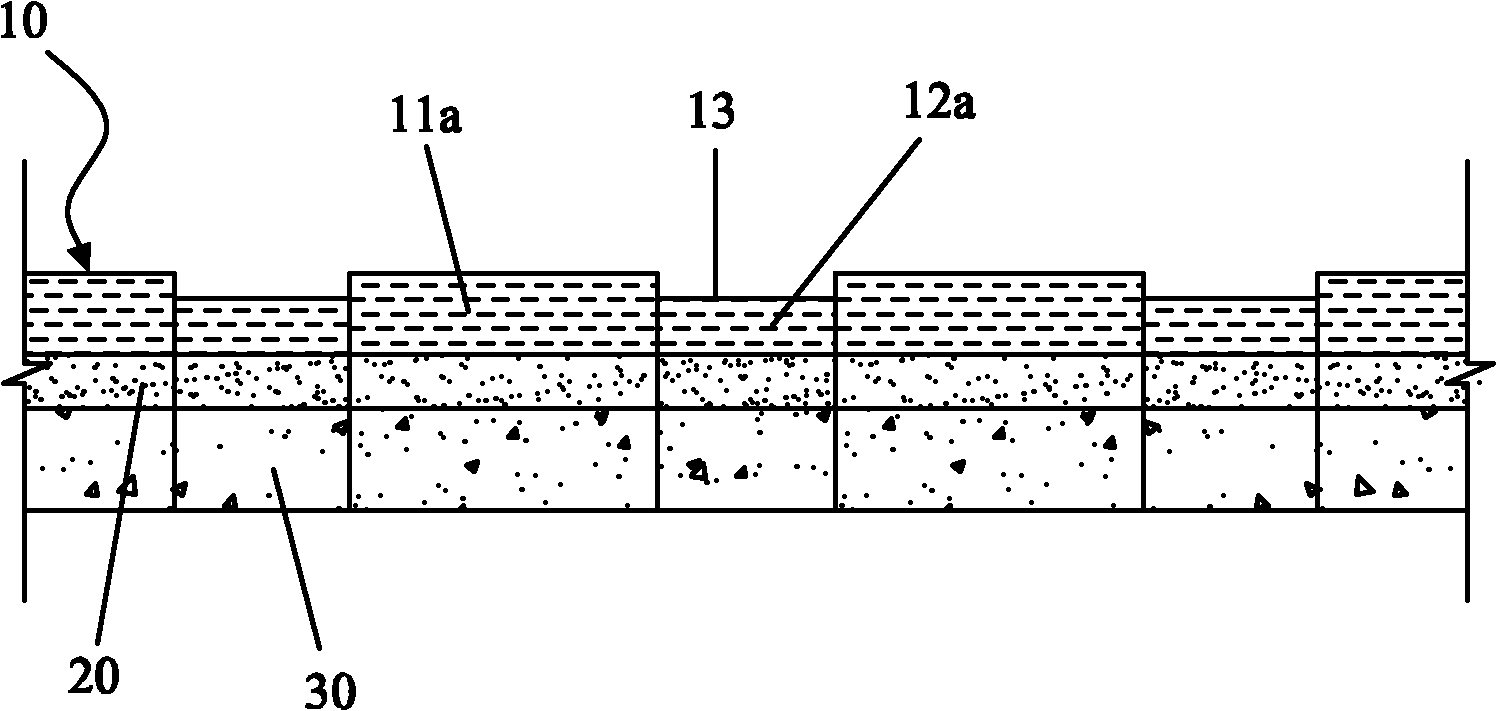

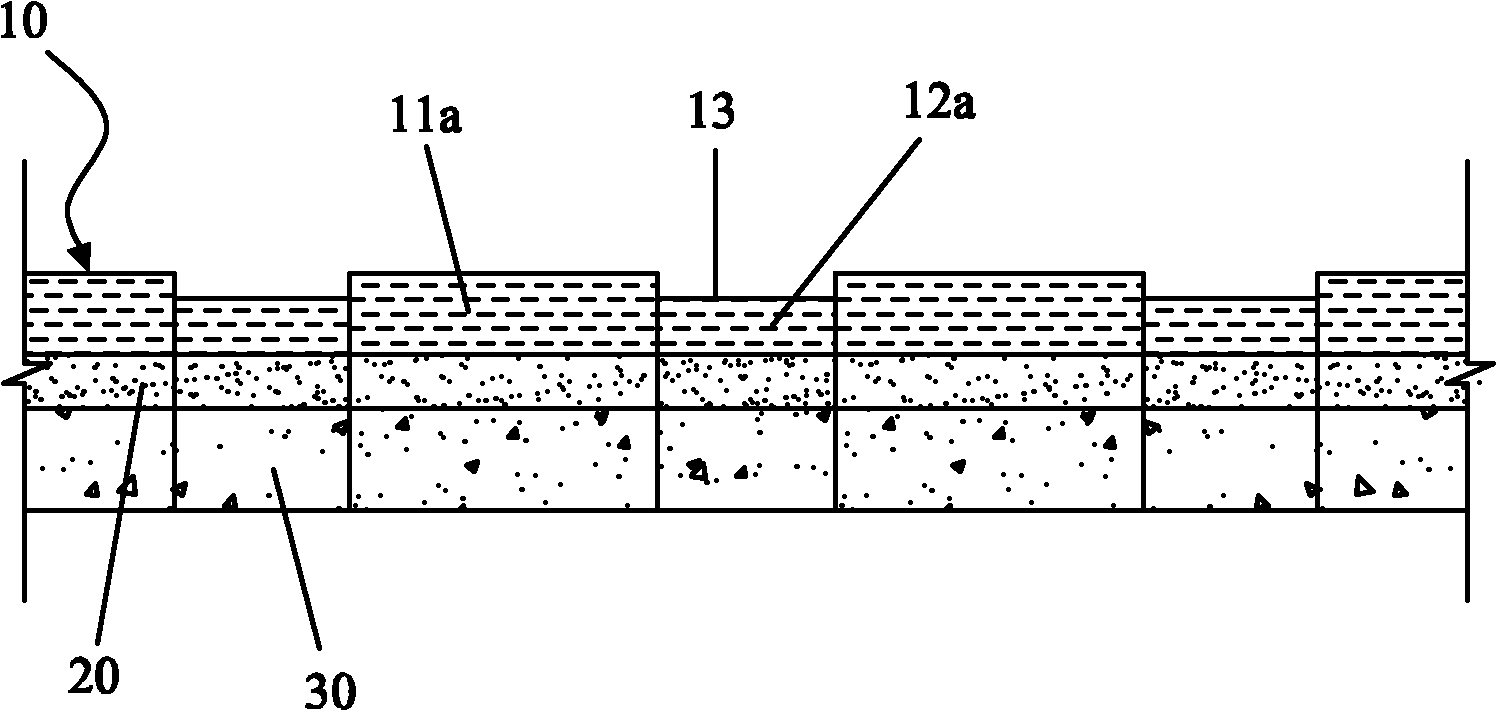

[0021] figure 1 with figure 2 A top view and a cross-sectional view of an embodiment of the anti-skid track according to the present invention are shown respectively. exist figure 2 In the shown embodiment, the anti-skid lane 10 according to the present invention is laid on the concrete lane base 30 , and a cement mortar layer 20 is laid between the concrete lane base 30 and the anti-skid lane 10 . The anti-skid roadway 10 of the present invention is made up of plates 11a, 12a with different thicknesses. The anti-skid roadway 10 includes a plurality of first thickness rows 11 and a plurality of second thickness rows 12 arranged alternately in sequence, wherein the first thickness row 11 includes a plurality of The first thickness plate 11a; the second thickness row 12 includes a plurality of sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com