Multilayer integrated multi-angle edge nest hole and core hole structure

An integrated, nest-hole technology, applied in the direction of sheet/board, building components, etc., can solve the problems of high scrap rate of edge strips, single structure, and inability to adopt connection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

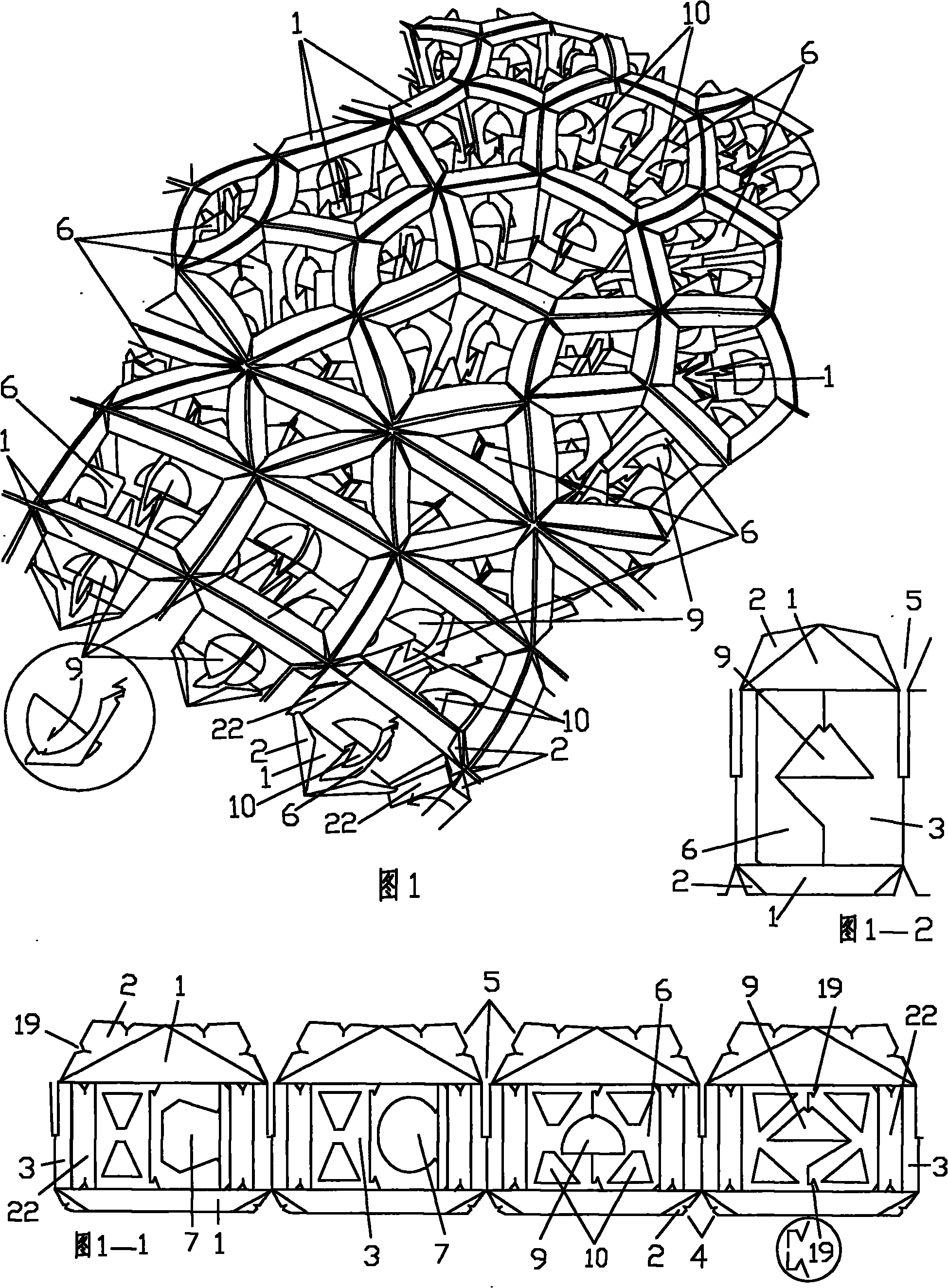

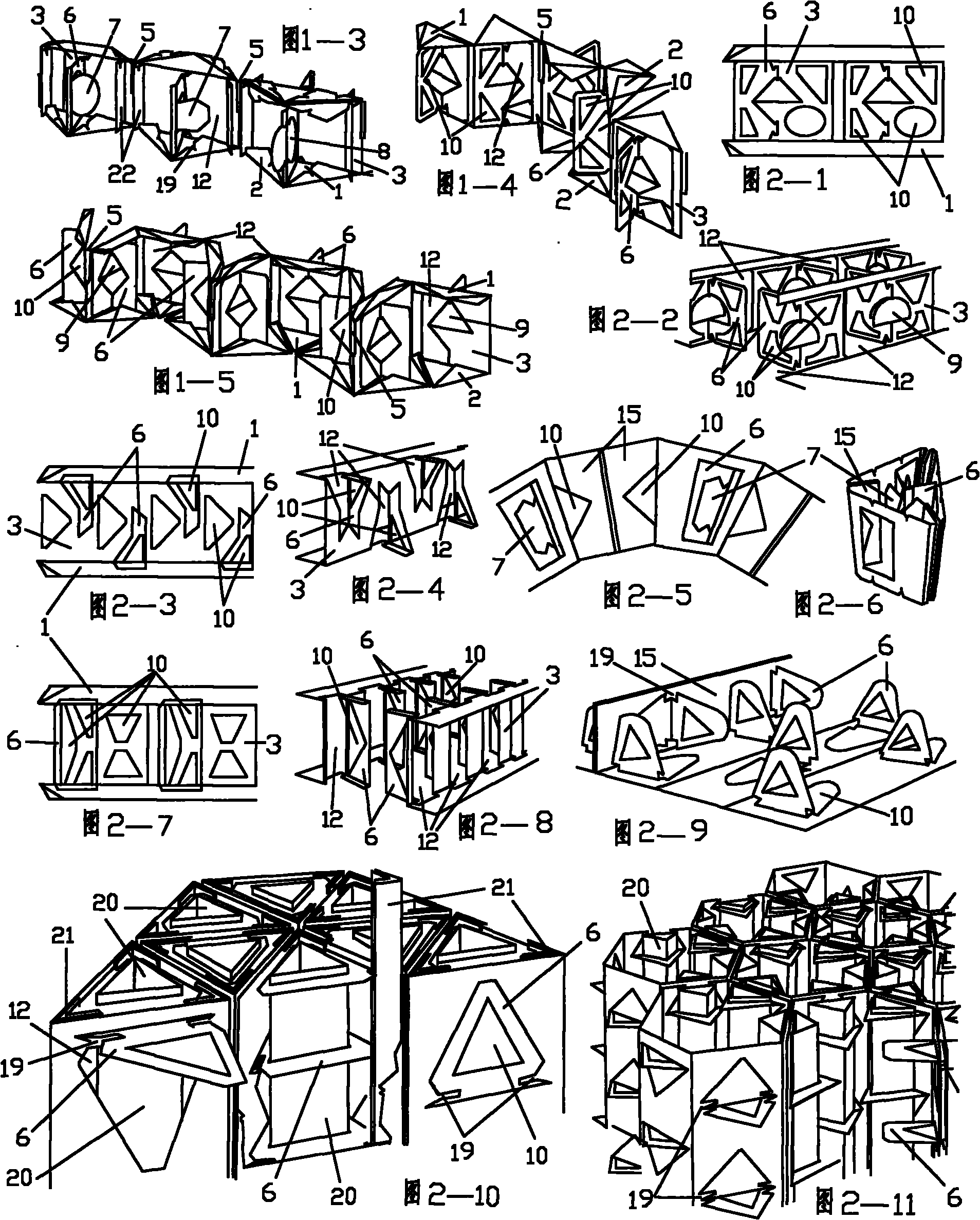

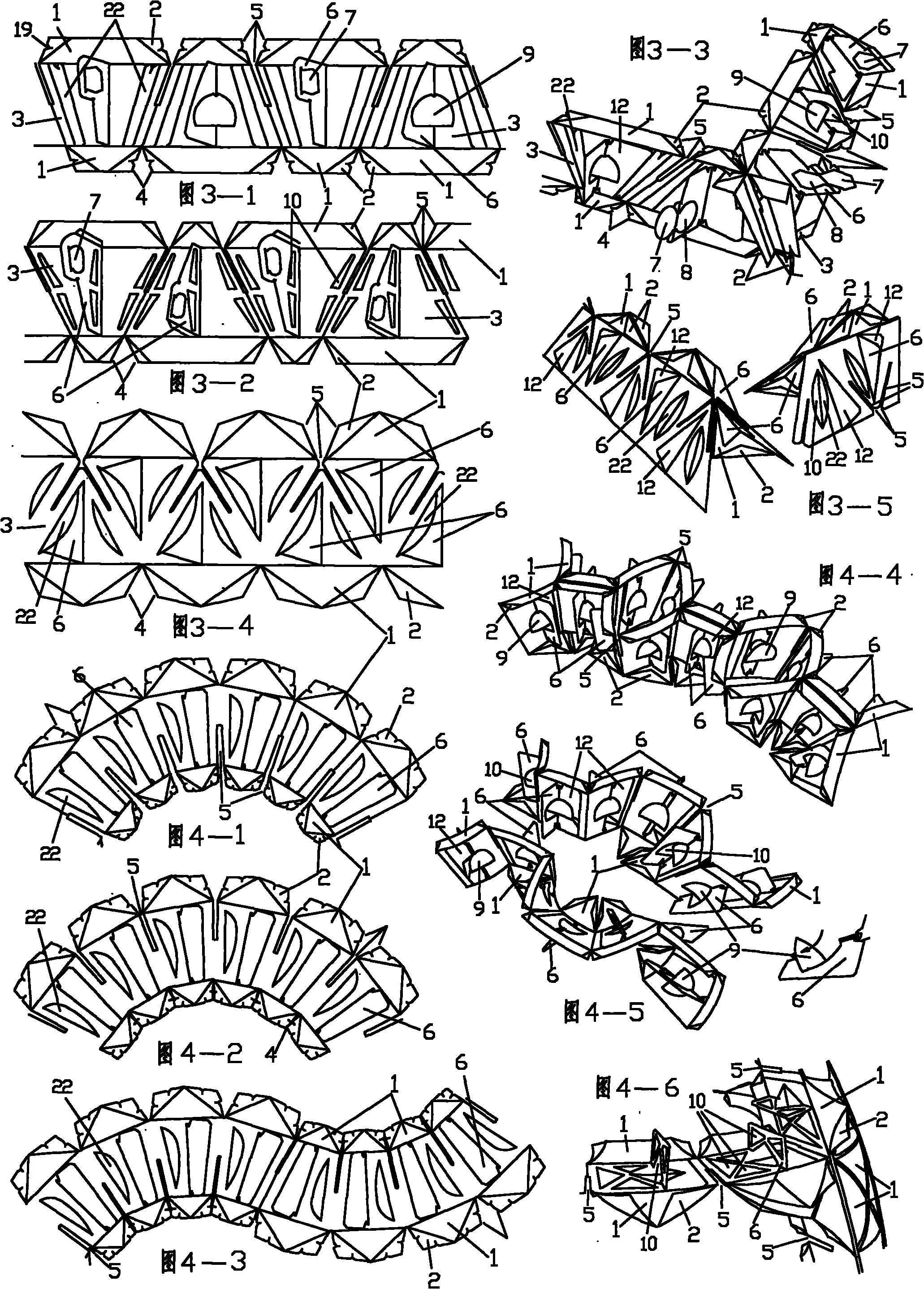

[0066] With reference to the drawings, the multi-layer integrated multi-corner side nest hole core hole structure of the present invention will be described in detail as follows:

[0067] The multi-layer integrated multi-corner side nest hole core hole structure provided by the present invention includes various combined structural templates, components and structural combinations processed from metal or non-metal plates to form a multi-layer integrated triangular edge, four corners, and five corners Edge, hexagonal edge and other multi-angle edge nest hole core hole structure, such as figure 1 .

[0068] The combined structure type plate and its structure include an upper and lower folded plate 1, an inner corner 2 and a middle folded plate 3 provided with a joint 4, a joint socket 5, an insert plate 6, a tongue 7, a tongue hole 8, a support plate 9, Intubation hole 10, card plate 11, socket 12, center folding plate 13, edge folding plate 14, slot folding plate 15, dovetail teeth,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com