Optical film

A technology of optical film and prism structure, applied in the field of optical film, can solve problems such as limited optical interference, achieve the effect of avoiding optical interference and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

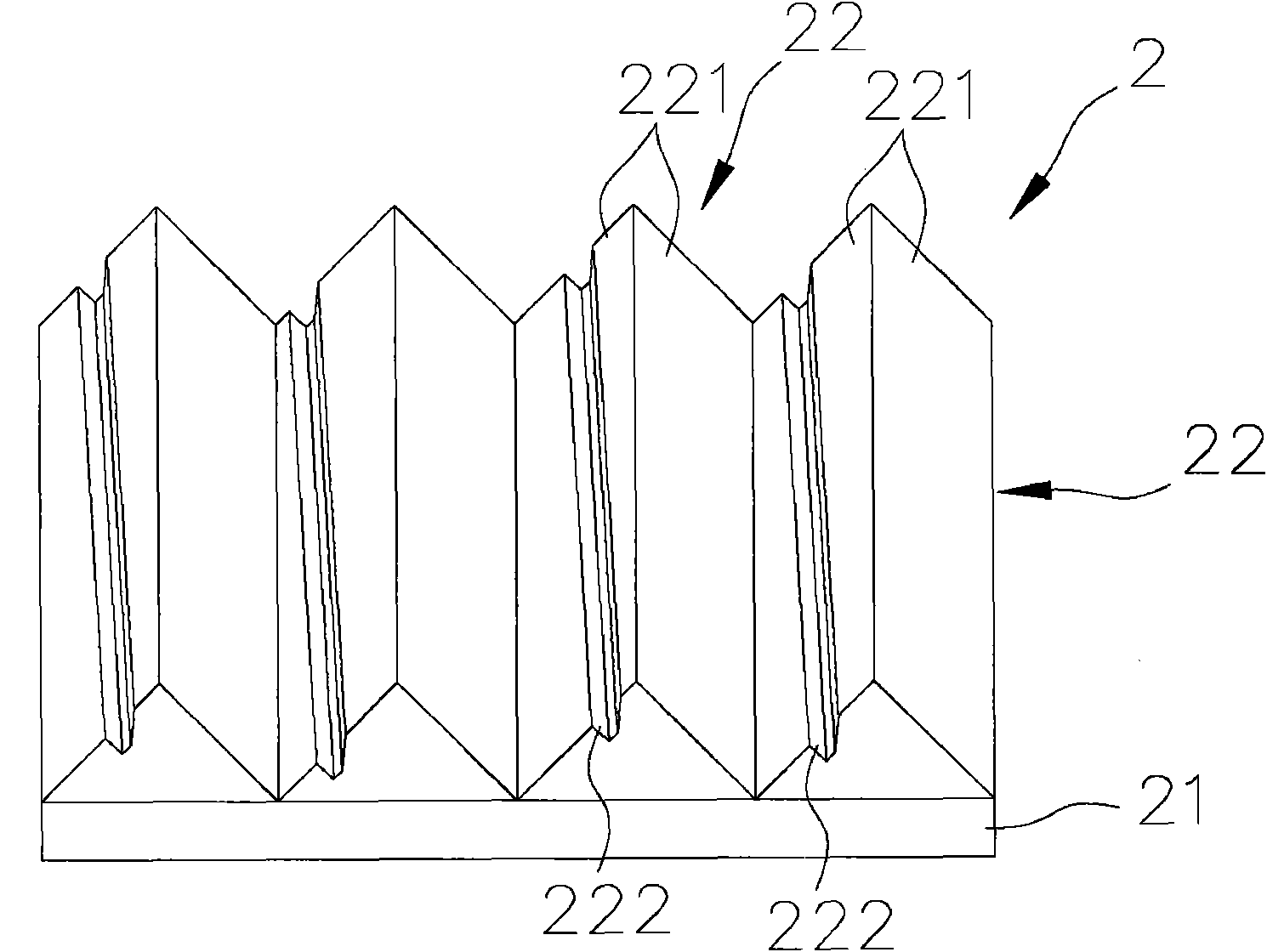

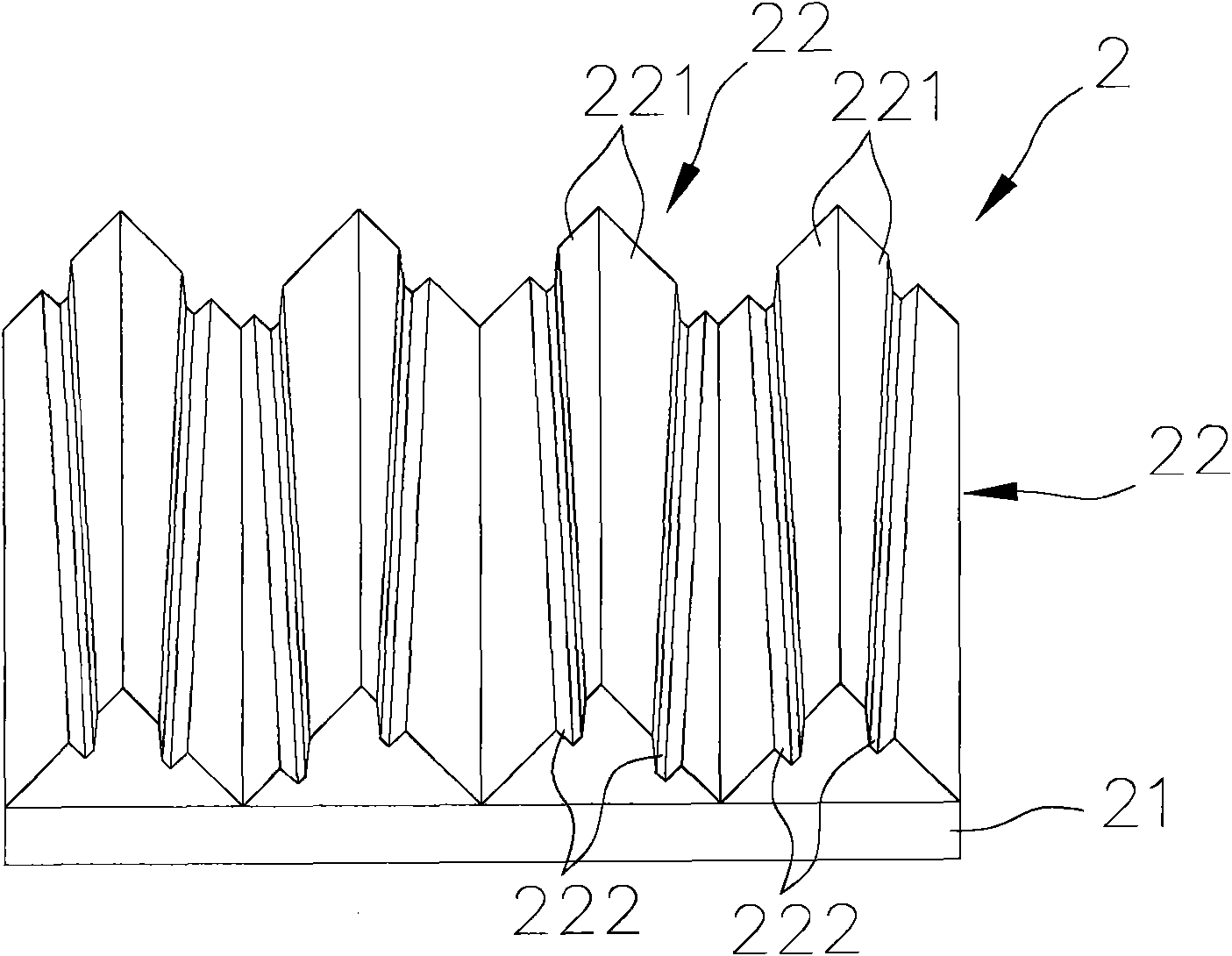

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

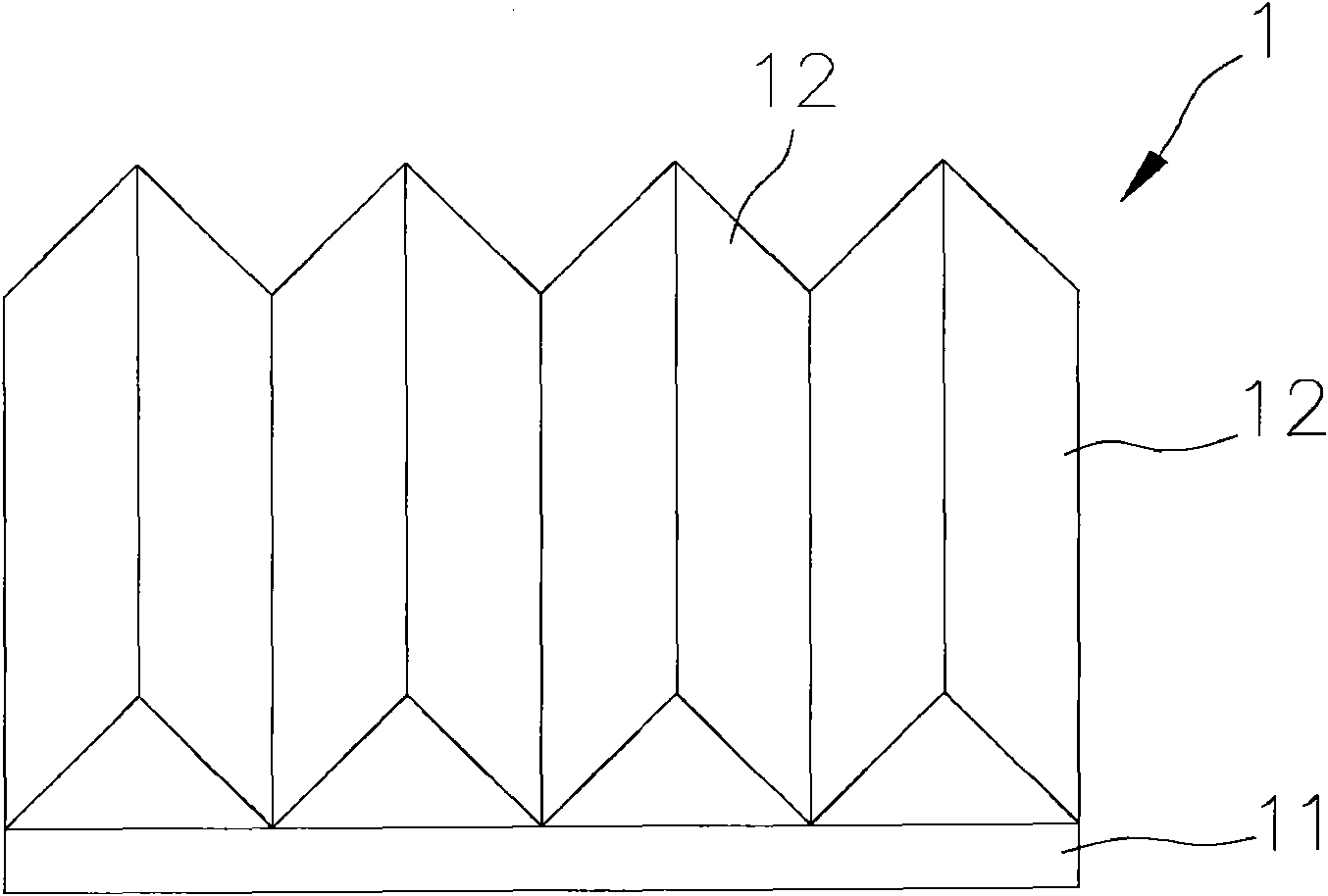

[0018] refer to figure 2 , a preferred embodiment of an optical film 2 of the present invention includes a substrate 21 and a plurality of prism structures 22 .

[0019] The substrate 21 is made of glass or plastic, wherein the plastic material is selected from polyester resin, polyacrylate resin, polyolefin resin, polycarbonate resin ), polyurethane resin (polyurethane resin), or triacetate cellulose (TAC, triacetate cellulose), etc.

[0020] The plurality of prism structures 22 are made of light-transmitting materials with a refractive index of 1.3-2.0, and are elongated and substantially parallel formed on the substrate 21 to have an excellent light-gathering effect. Here, the plurality of prism structures Each prism structure 22 is made of a material selected from thermosetting resin, acrylic resin, or ultraviolet curing resin.

[0021] In detail, each p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com