Core-crossing microstructure sensing optical fiber

A technology of sensing fiber and microstructure, applied in the direction of cladding fiber, optical waveguide light guide, etc., can solve the problems of unsuitable long-distance use, difficult coupling, and large fusion loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

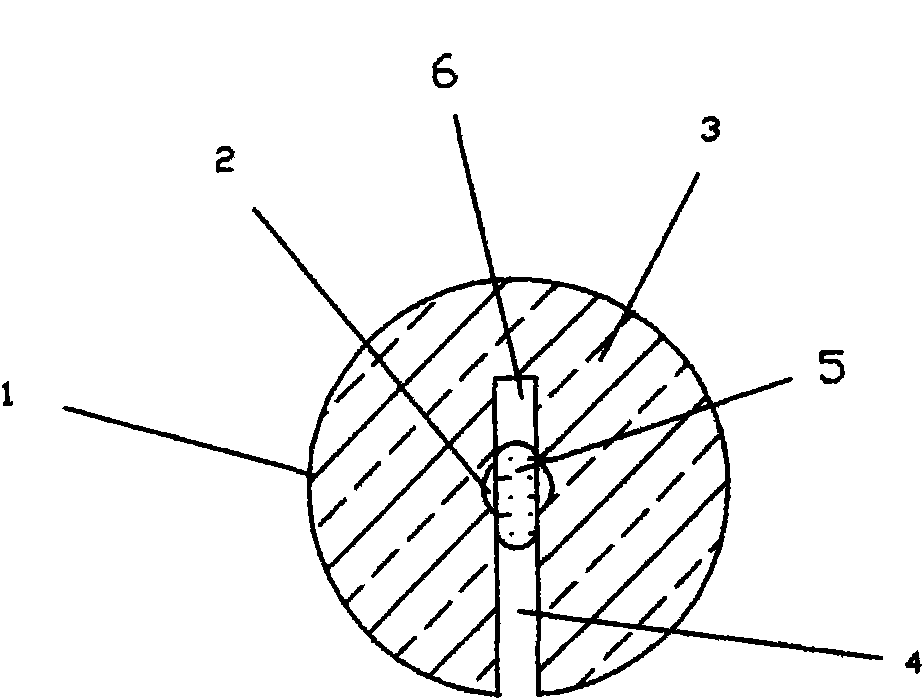

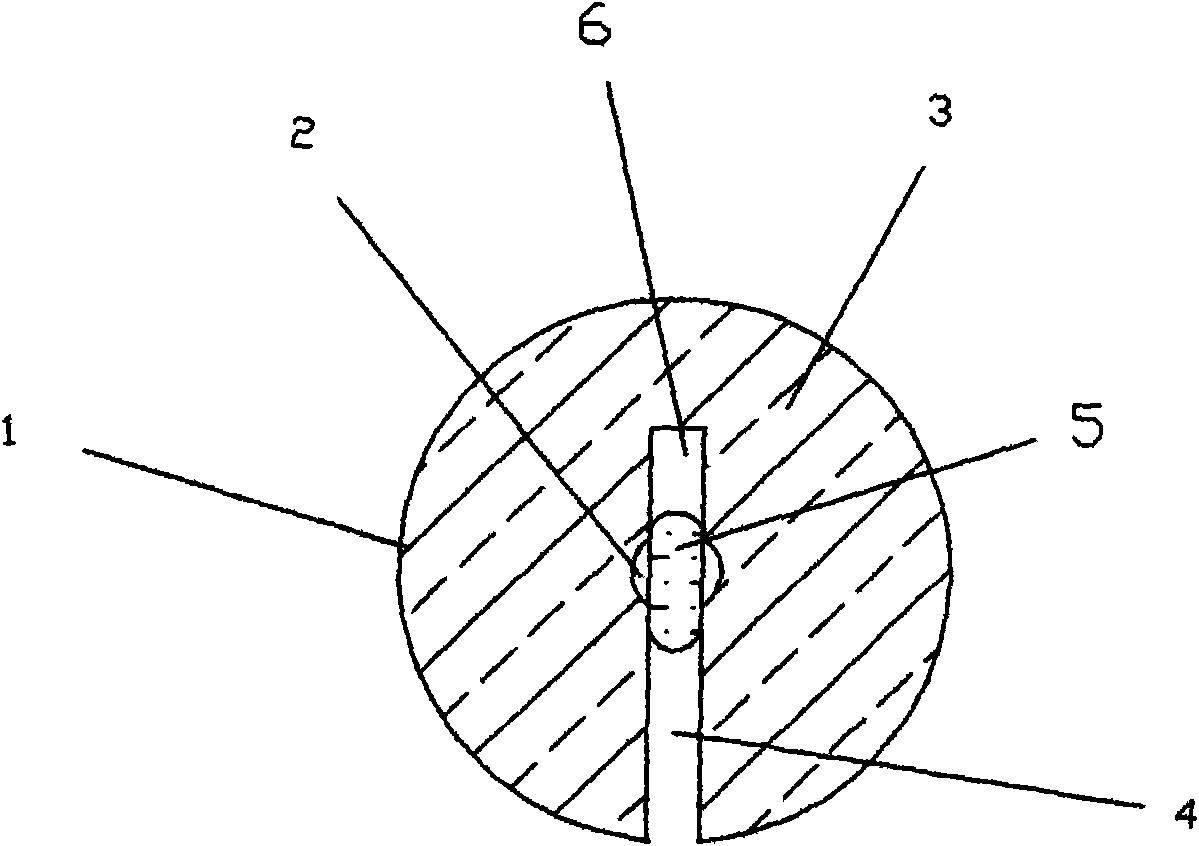

[0016] figure 1 , 2 It is a cross-sectional and longitudinal cross-sectional schematic view of the microstructured optical fiber according to the present invention. There is an optical fiber core 2 with a slightly higher refractive index in the optical fiber matrix 1, and an optical fiber cladding 3 is formed on the periphery of the optical fiber core 2. In the optical fiber cladding 3, there is a microhole 4 at the position passing through the optical fiber core 2. In the microhole A part of 4 is filled with a refractive index matching liquid 5, and one end of the microhole is an opening, thus forming a microstructured sensing fiber, the optical signal is transmitted in the fiber core 2, and the filled refractive index matching liquid in the microhole 4 The liquid 5 will reduce the loss of the optical signal transmitted in the optical fiber core 2 at the intersection with the microhole 4. When the external physical quantity changes, the air in the cavity 6 in the microhole w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com