Flexible flat cable structure

A soft flat, wire-structured technology, applied in the direction of flat/ribbon cables, conductors, fixed connections, etc., can solve the problems of twisted extrusion deformation, twisted double fold, lateral double fold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention are described in detail below with reference to the drawings.

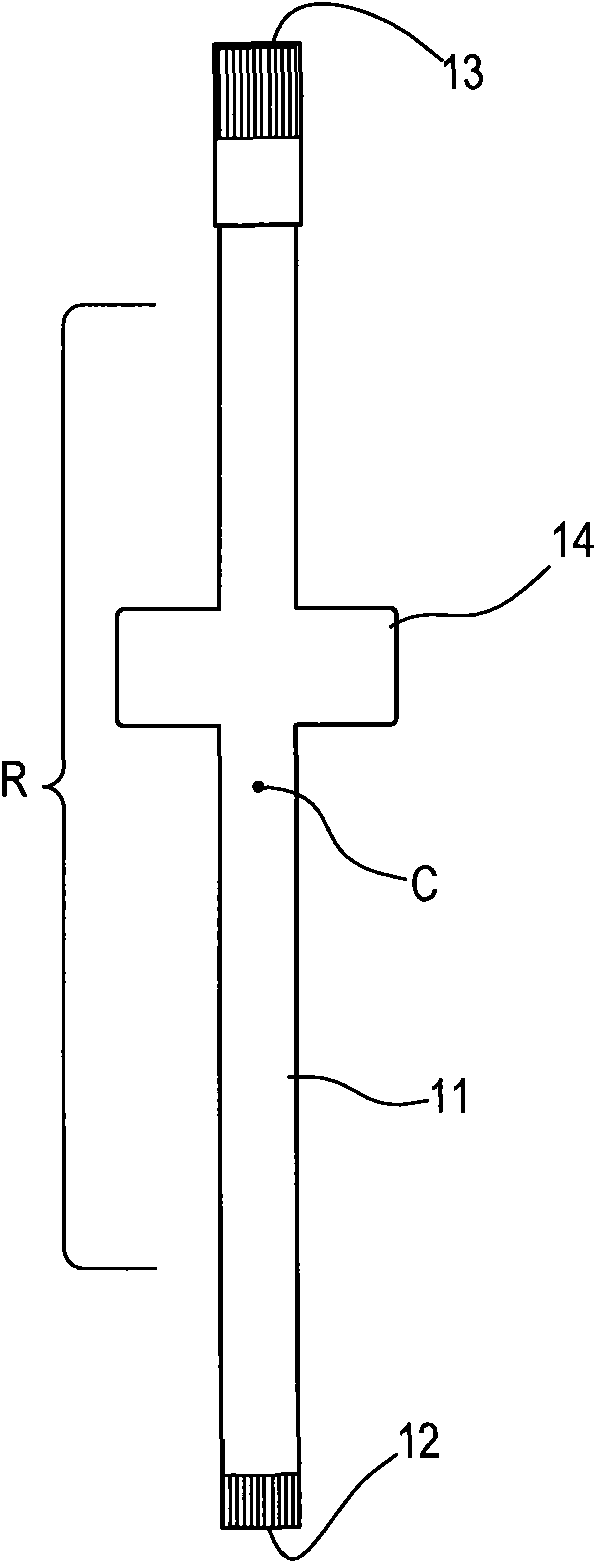

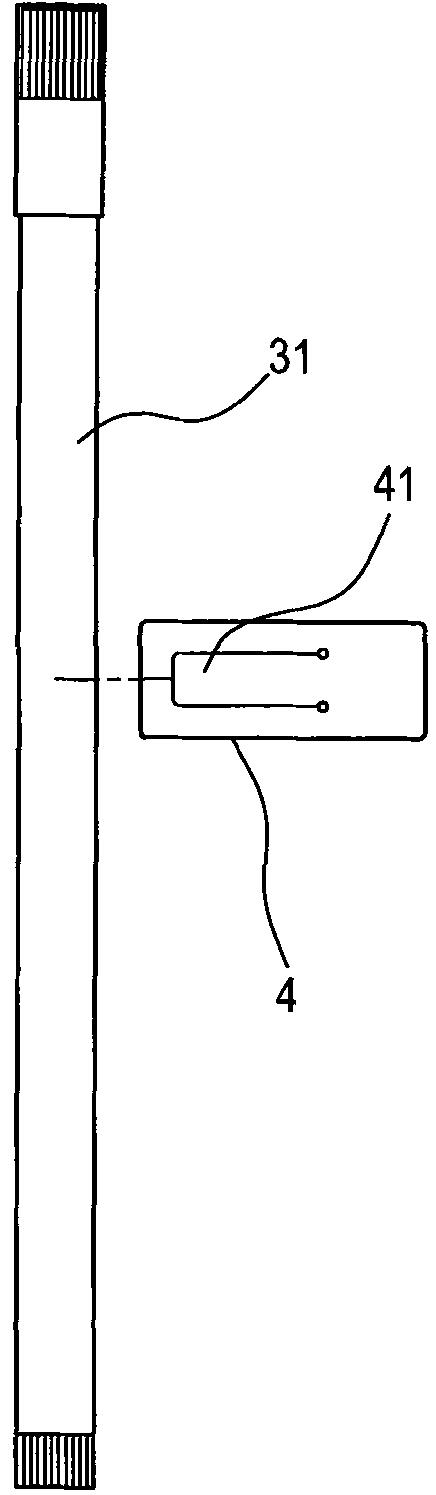

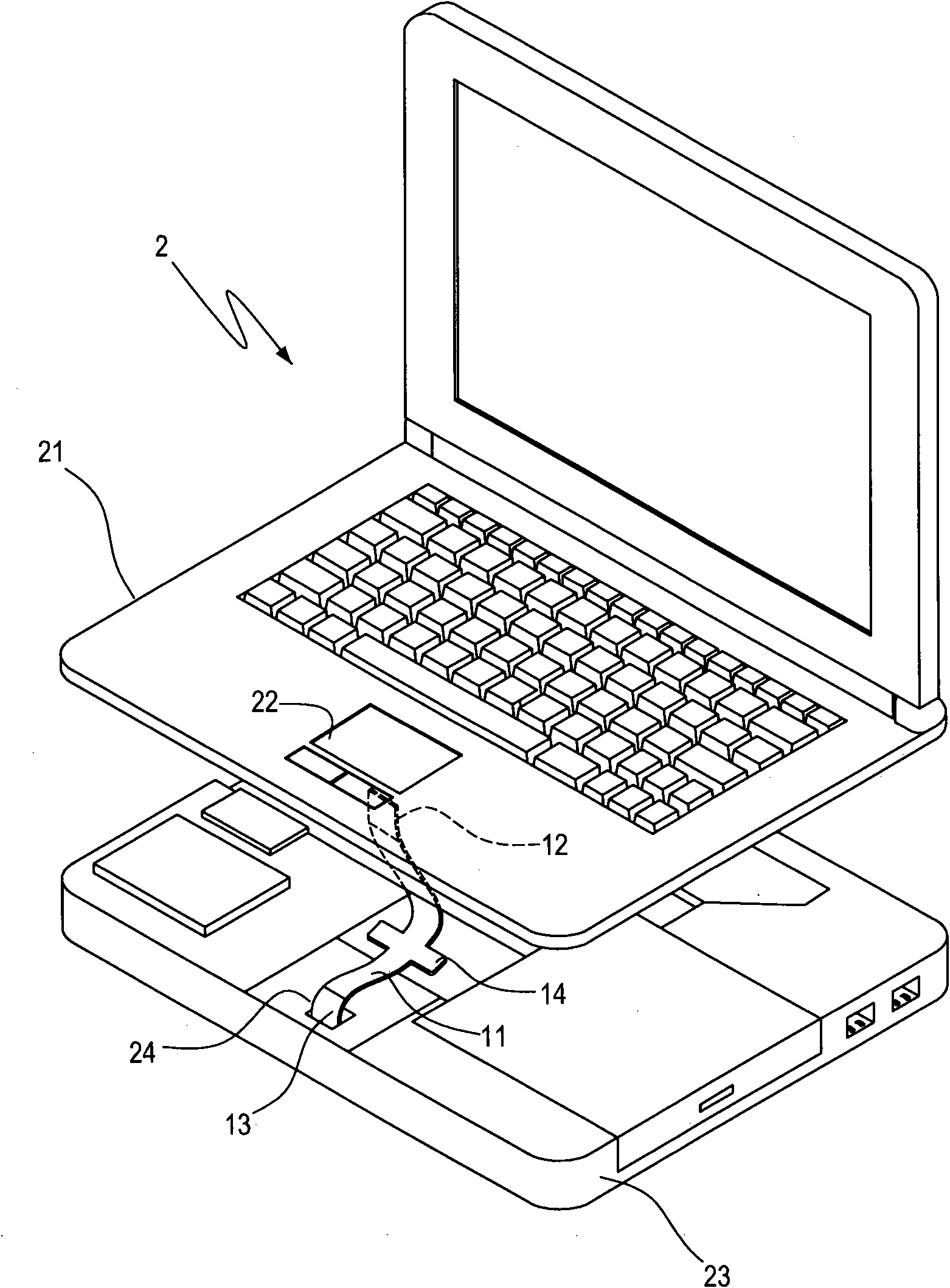

[0019] Please refer to figure 1 and figure 2 , figure 1 It is a schematic plan view of the present invention, figure 2 It is a schematic diagram of the use state of the present invention.

[0020] The flexible flat cable structure of the present invention has a cable 11. The cable 11 has an appropriate length and width and is roughly elongated. Both ends of the cable 11 have a first connecting end 12 and a second Connecting end 13, the first connecting end 12 and the second connecting end 13 are respectively connected to different devices or circuit boards, and there is a fin 14 in the middle section of the cable 11, the width of the fin 14 is at least about the row Twice the width of line 11, but not limited to twice.

[0021] In this embodiment, the integral structure of the fin 14 and the cable 11 is taken as an example for illustration and draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com