Swivel drive controller and construction machine including the same

A technology of construction machinery and drive control, which is applied to the arrangement of multiple prime movers of the general power plant, power plant, AC motor control, etc., and can solve problems such as deterioration of ride quality, impact, and damage to the gears of the slewing mechanism in the slewing drive , to achieve the effect of good riding feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

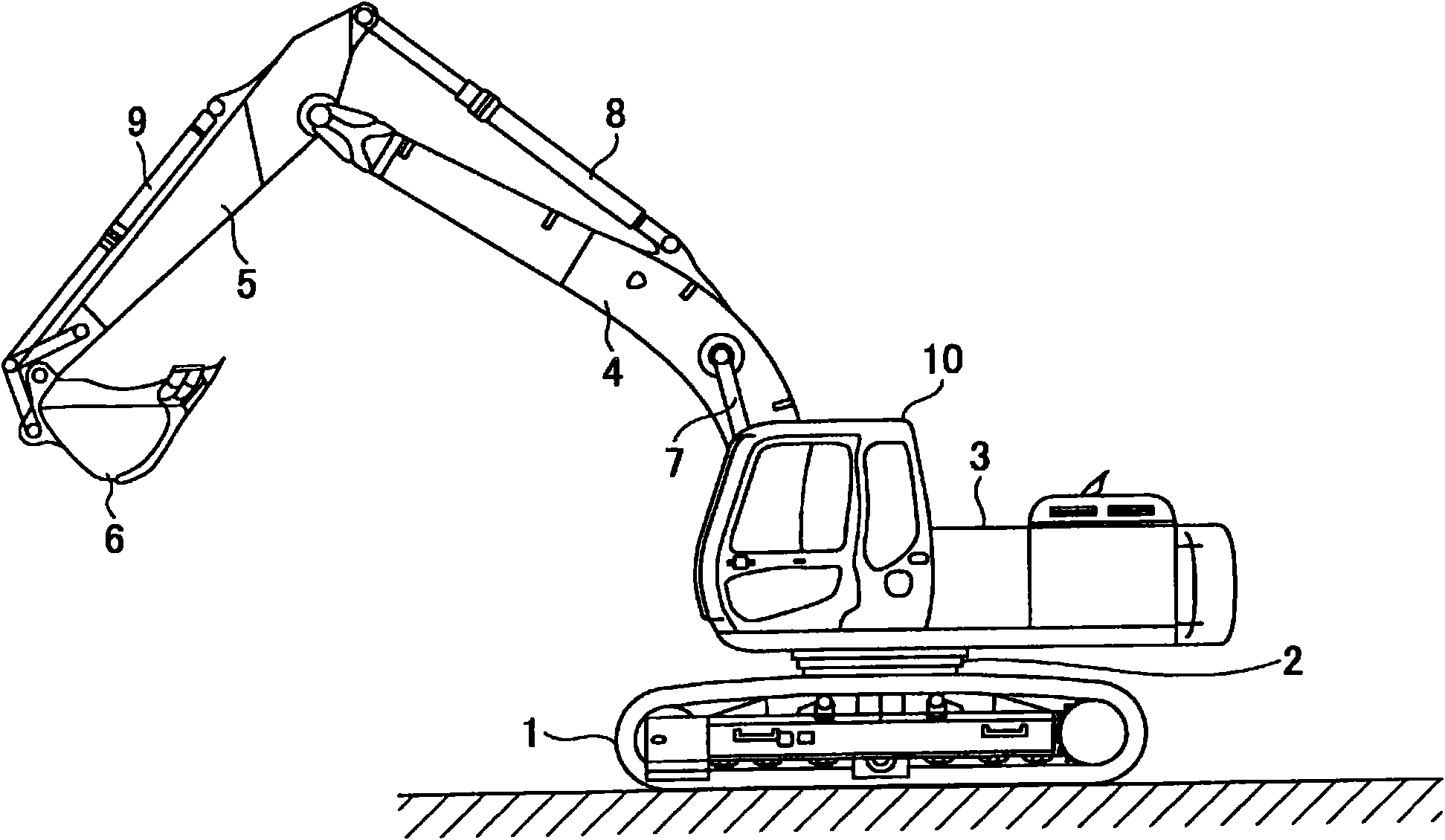

[0032] figure 1 It is a side view showing a construction machine including the turning drive control device according to the first embodiment.

[0033] A revolving upper body 3 is mounted on an undercarriage 1 of the construction machine via a revolving mechanism 2 . Furthermore, in addition to the boom 4, the arm 5, and the bucket 6, and the boom cylinder 7, the arm cylinder 8, and the bucket cylinder 9 for hydraulically driving them, the upper slewing body 3 is equipped with a cab 10 and a power supply. source.

[0034] "the whole frame"

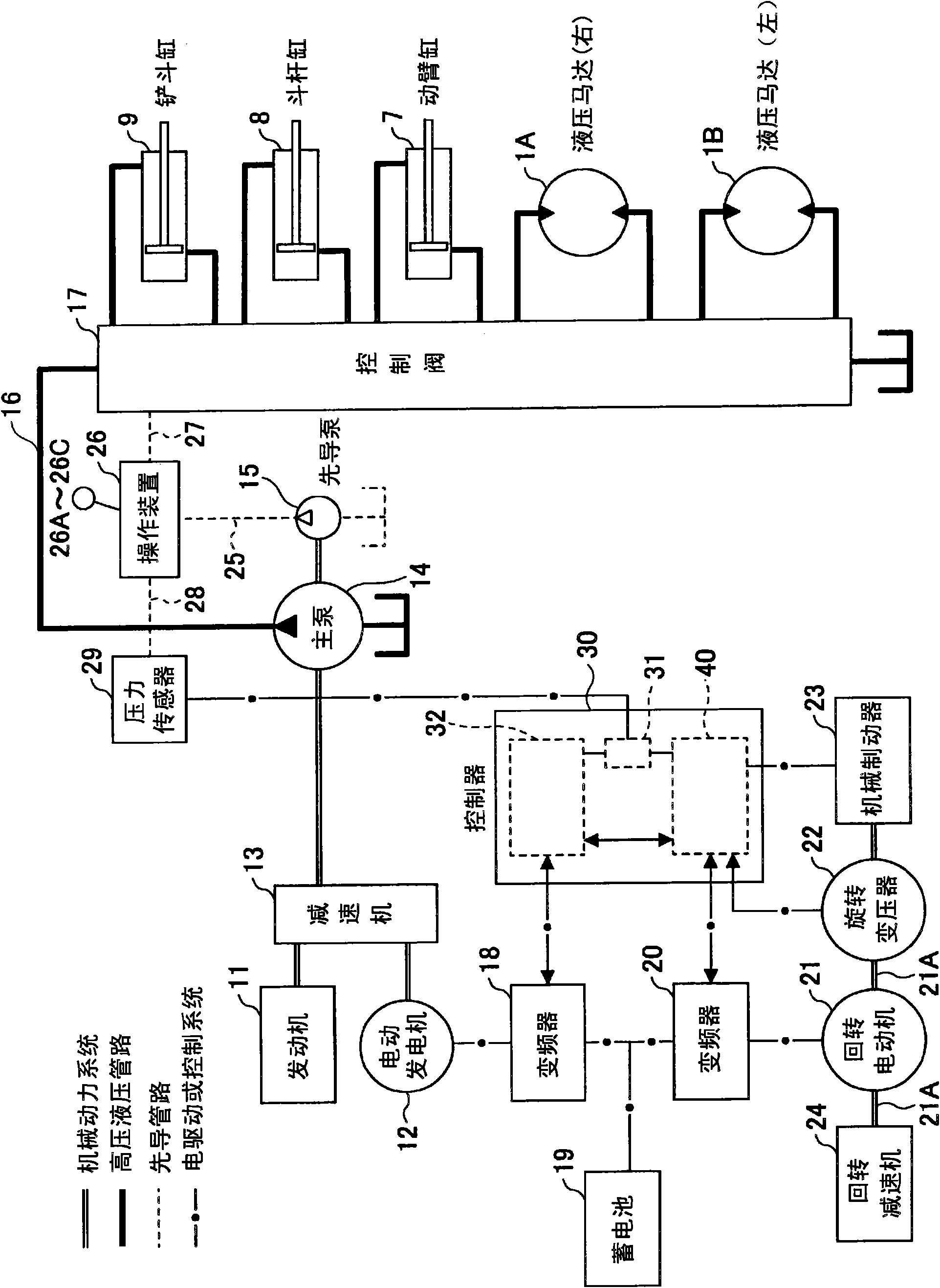

[0035] figure 2 It is a block diagram showing the configuration of a construction machine including the turning drive control device according to the first embodiment. in the figure 2 Among them, double lines, solid lines, dotted lines, and single-dot-dash lines represent mechanical power systems, high-pressure hydraulic lines, pilot lines, electric drive or control systems, respectively.

[0036] An engine 11 as a mechanical drive...

Embodiment approach 2

[0144] Figure 7 It is a control block diagram showing the configuration of the turning drive control device 40 according to the second embodiment. In Embodiment 1, a method was described in which the acceleration as the amount of time change of the rotational speed input from the turning motion detection unit 58 is calculated, and the direction of the acceleration is set as the torque direction (rotational rotation) of the turning shaft of the turning mechanism 2 . The torque direction on the rotating shaft 21a of the motor 21 is detected, and the rotation drive control is performed using the torque direction, but the difference between the rotation drive control device 40 of the second embodiment and the first embodiment is that based on The output torque current command value determines the direction of the torque and carries out the turning drive control. The other components are the same as those in Embodiment 1, so the same symbols are assigned to the same components an...

Embodiment approach 3

[0155] Figure 9 It is a control block diagram showing the configuration of the turning drive control device 40 according to the third embodiment. The turning drive control device 40 of Embodiment 3 is different from Embodiment 1 in that it includes an accelerometer 70 as a mechanism for detecting the turning direction, and the main control unit 60 detects the torque direction based on the acceleration detected by the accelerometer 70 (the turning motor 21 The torque direction on the rotating shaft 21a). The other components are the same as those in Embodiment 1, so the same symbols are assigned to the same components and their descriptions are omitted.

[0156] The main control unit 60 of the turning drive control device 40 according to Embodiment 3 detects the torque direction of the turning shaft of the turning mechanism 2 (the torque direction on the turning shaft 21a of the turning electric motor 21) based on the acceleration input from the accelerometer 70, and performs...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap