Dust collection barrel of dust collector

A technology for dust buckets and vacuum cleaners, applied in the field of dust buckets, can solve problems such as inconvenience in use and inability to compress dust, and achieve the effects of increasing dust holding capacity, fully compressing, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

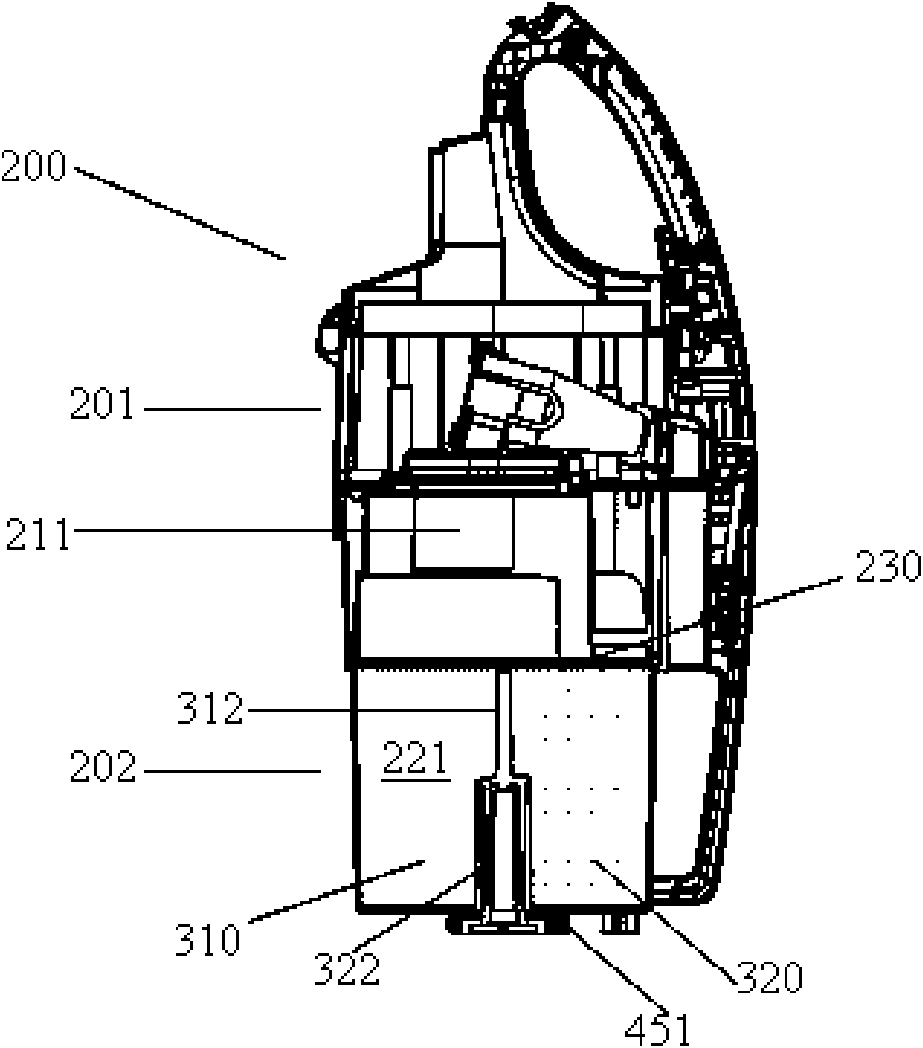

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0034] It is worth noting that the dust bucket of the vacuum cleaner of the present invention can be conveniently applied to vertical vacuum cleaners and horizontal vacuum cleaners, both of which can achieve good application effects.

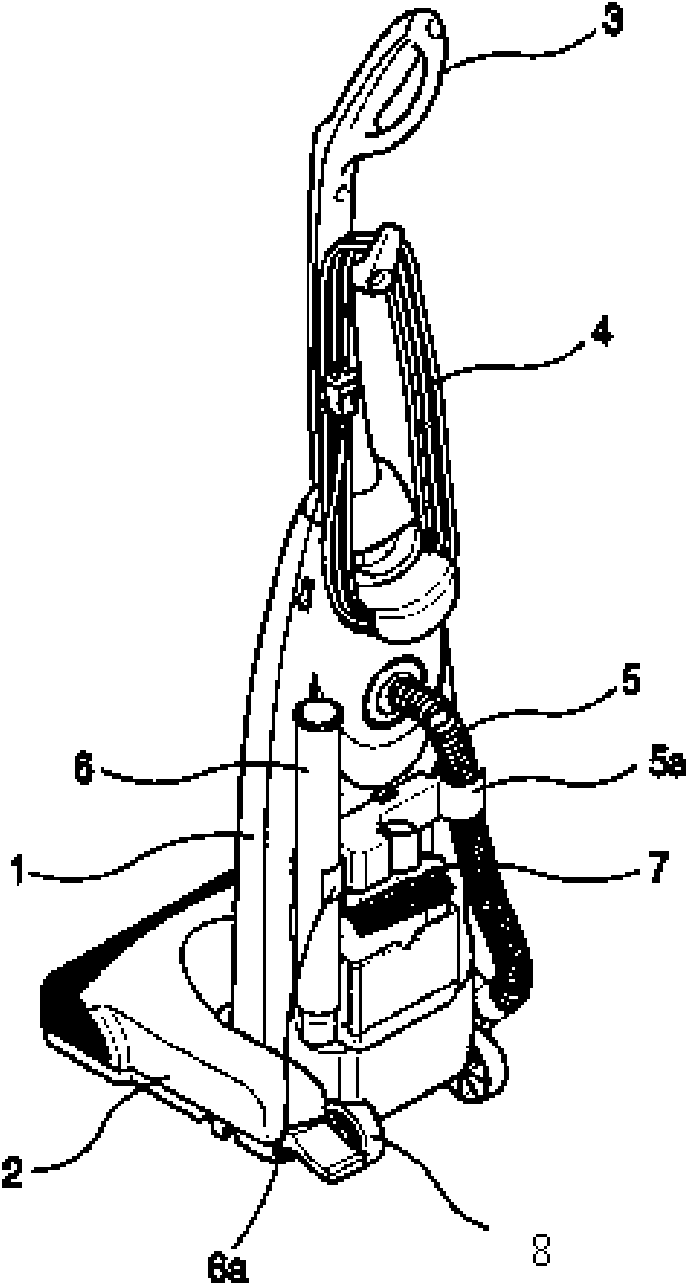

[0035] The following will take an upright vacuum cleaner as an example for further explanation.

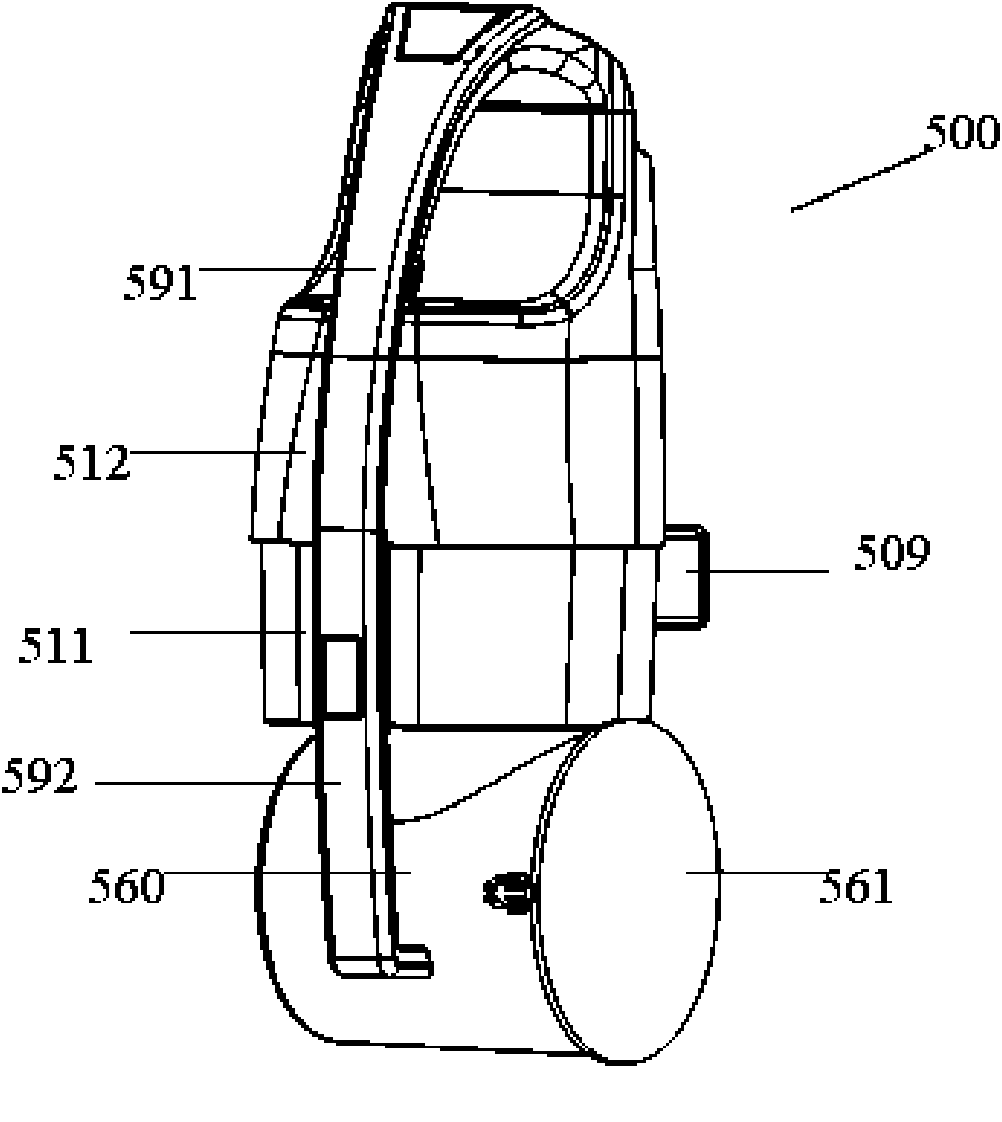

[0036] like image 3 , as shown in 4, 5, and 6, the dust collector 500 includes: a cyclone 511 is used to separate the dust from the introduced gas by using the centrifugal force difference between the gas and the dust, and a suction port 509 is provided on its side; it is arranged on the upper part of the cyclone 511 and a horizontal dust bucket 560 that stores dust separated from the inhaled gas by the cyclone tube 511 and the dust filter bucket 512, the horizontal dust bucket 560 is placed horizontally below the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com