Air-driven rotary cutting tool

An air-driven, cutter technology, used in medical science, prosthodontics, dentistry, etc., can solve problems such as small head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

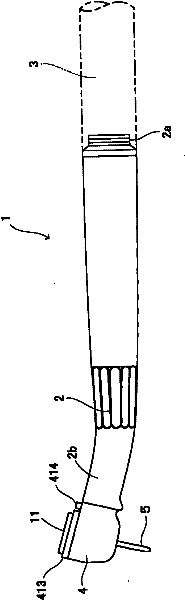

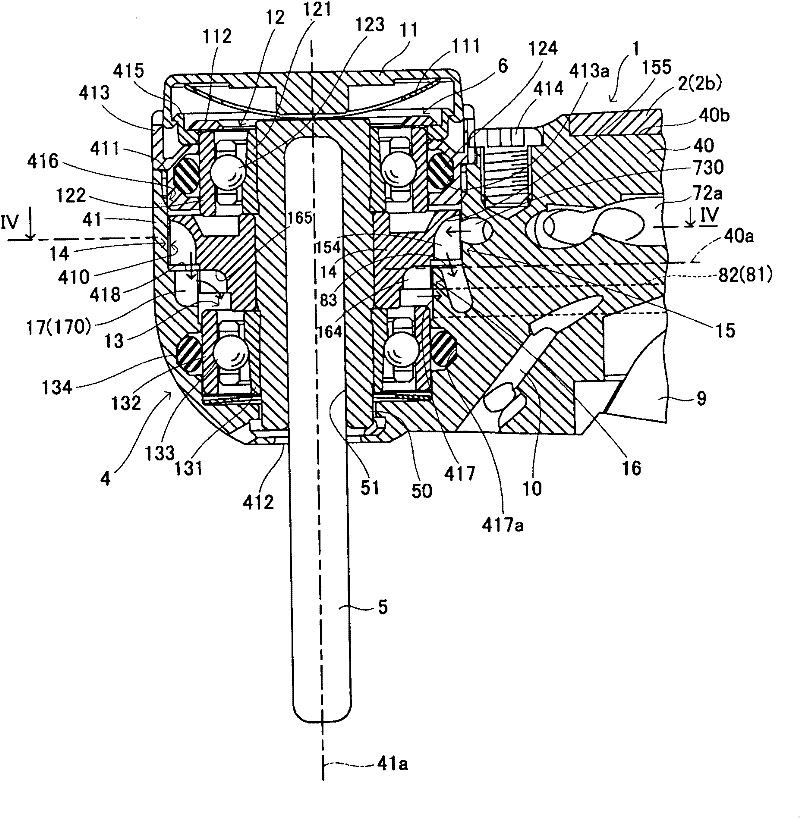

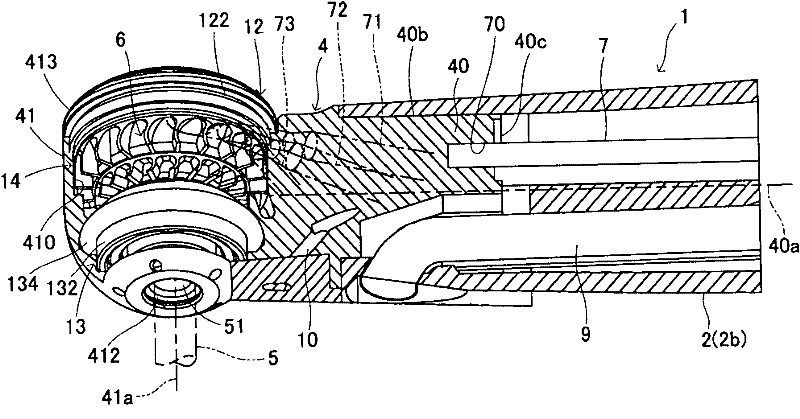

[0037] Hereinafter, an embodiment of the air-driven rotary cutter of the present invention will be described based on the drawings. figure 1 It is a side view showing the overall structure of a dental air-turbine dental drill handpiece as an embodiment of the air-driven rotary cutter of the present invention. in figure 1 Among them, the dental drill handpiece 1 has a handle portion 2 that is held by the operator during treatment. The base end of the handle portion 2 is provided with a medium for interacting with air, water, etc., like conventional dental drill handpieces. The connecting portion 2a to which the supply pipe 3 is connected has a head 4 connected to the front end of the handle portion 2 via a neck portion 2b. The cutting tool 5 is detachably attached to the head 4. Figure 2 ~ Figure 4 Is to figure 1 An enlarged view of the head 4 and its vicinity. As shown in these drawings, the head 4 integrally includes a shaft portion 40 connected to the front end of the handle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com