Low-pollution flat grinding device

A low-pollution, flattening technology, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., can solve the problems of dust affecting the health of operators, achieve reduced adverse effects, simple design structure, and improved operation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

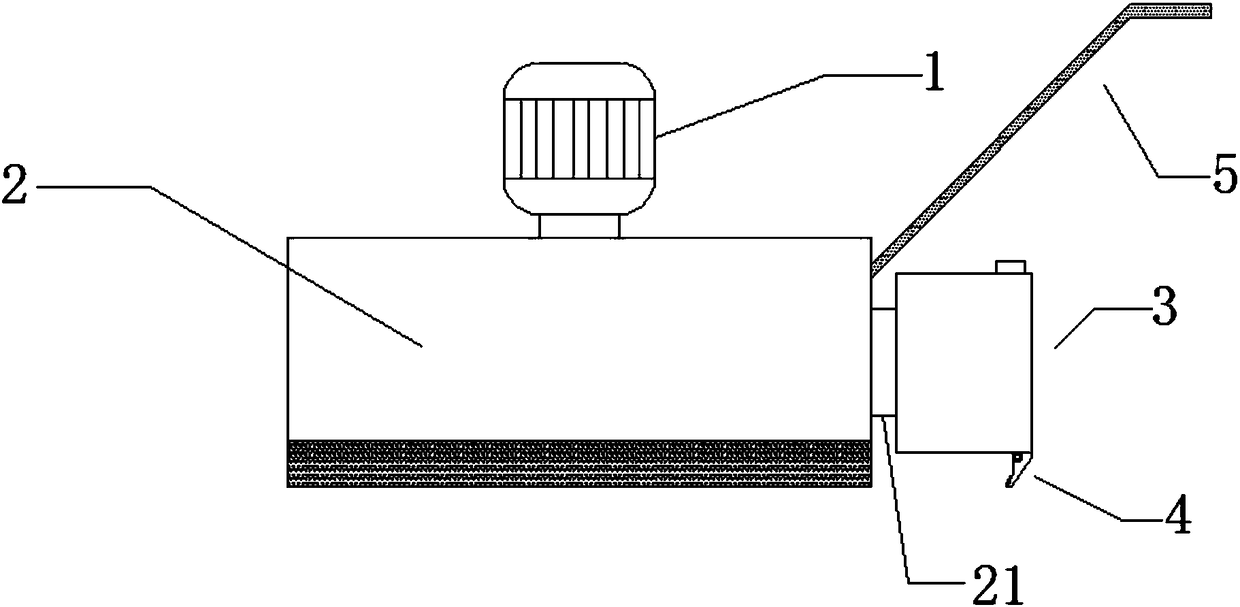

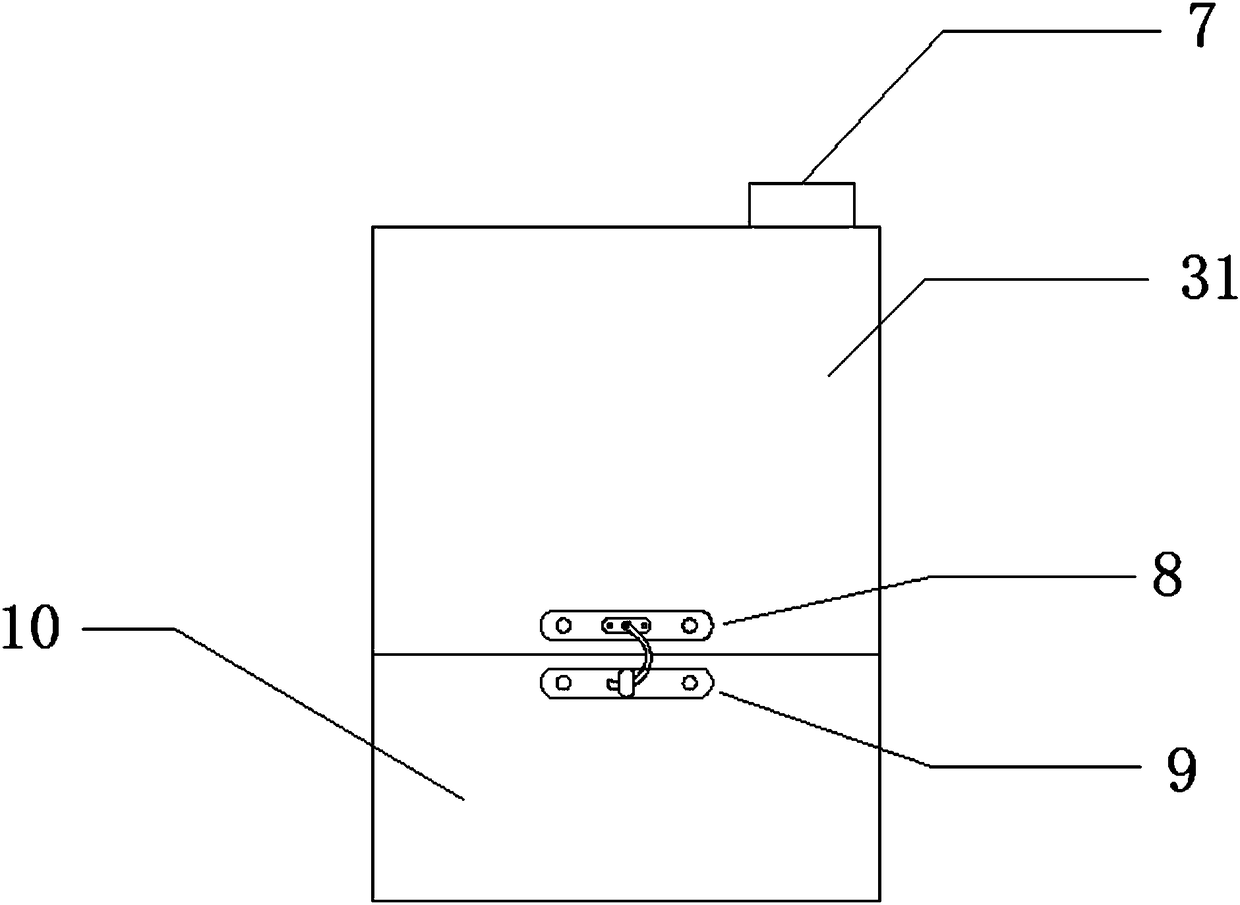

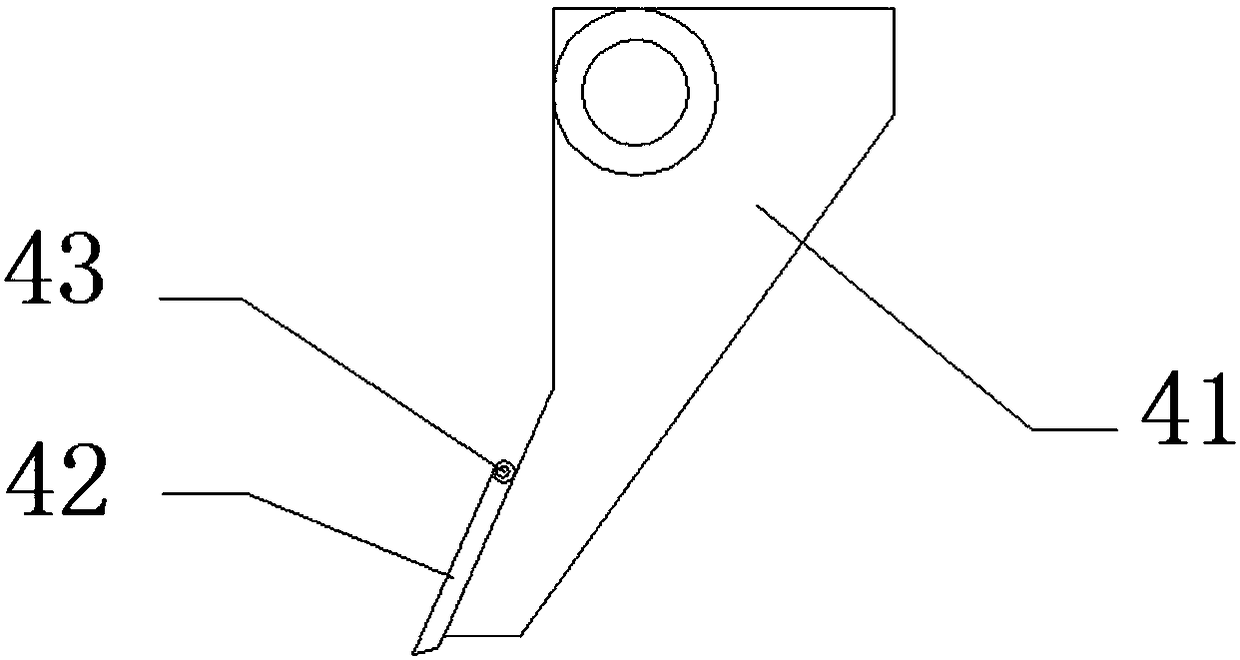

[0027] A low-pollution grinding device, comprising a first drive mechanism 1, a sanding disc 2 and a dust suction mechanism 3, a circular channel is provided on the outside of the grinding disc 2, and a dust suction port 6 is provided at the bottom of the circular channel, The ring channel is connected to the dust suction mechanism 3, and the bottom of the dust suction mechanism 3 is provided with a scraping mechanism 4. The dust collection mechanism 3 includes a dust collection box 31 , the control circuit and the dust suction assembly are located inside the dust collection box 31 , and the exhaust port 7 is located at the top of the dust collection box 31 . The control circuit includes a motor M connected to the working power supply at one end, the other end of the motor M is respectively connected to an inductor L and a capacitor C1, the other end of the inductor L is connected to a resistor R1, a bidirectional thyristor VS, and a capacitor C3, and the other end of the resis...

Embodiment 2

[0030] On the basis of Embodiment 1, a dust collection chamber 10 is provided at the inner bottom of the dust collection box 31, a buckle connection part 8 is provided on the dust collection box 31, and a buckle connection part 8 is provided on the dust collection chamber 10 to match The engaging part 9 of the dust collecting chamber 10 is connected with the dust collection box 31 by snapping. When the dust cannot be discharged into the external environment through the exhaust port 7, it will fall into the dust collection chamber 10, and the dust collection box 31 and the dust collection chamber 10 are connected by a buckle connection, so that the dust collection chamber 10 can be easily removed from the suction chamber. Taking out the dust box 31 also facilitates fixing the dust collecting chamber 10 in the dust collection box 31 . It achieves a good vacuuming effect and is easy to maintain.

Embodiment 3

[0032] On the basis of any of the above-mentioned embodiments, a push handle 5 is provided on the rear side of the sanding disc 2, which is convenient for the staff to control the direction of the device, and improves the convenience and reliability of the device operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com