Steel rail flash welding machine and container type steel rail flash welding equipment

A flash welding machine, flash welding technology, applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve the problems of non-retractable boom, inability to adjust the boom, high noise of the pump station, etc., to achieve long service life, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

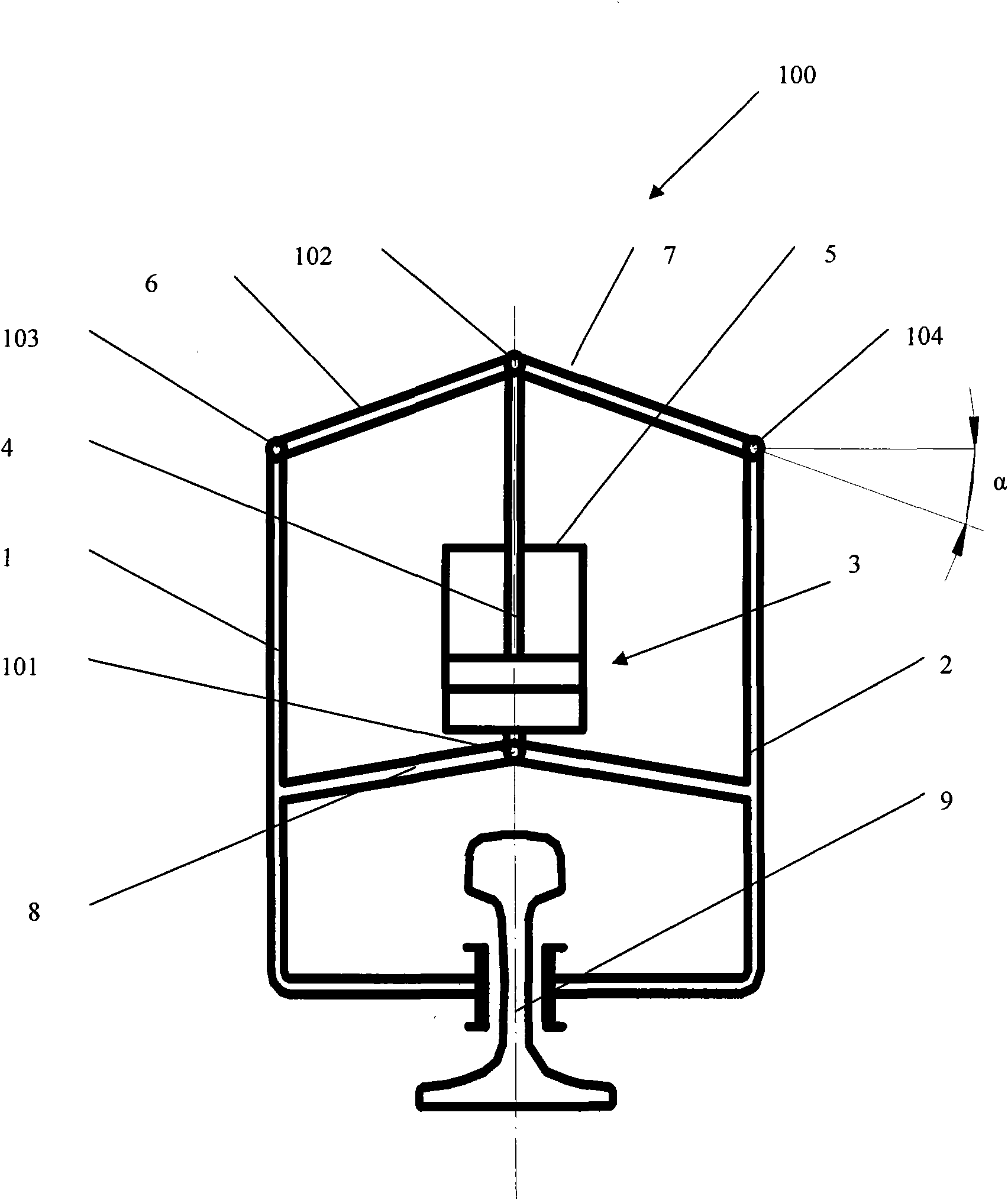

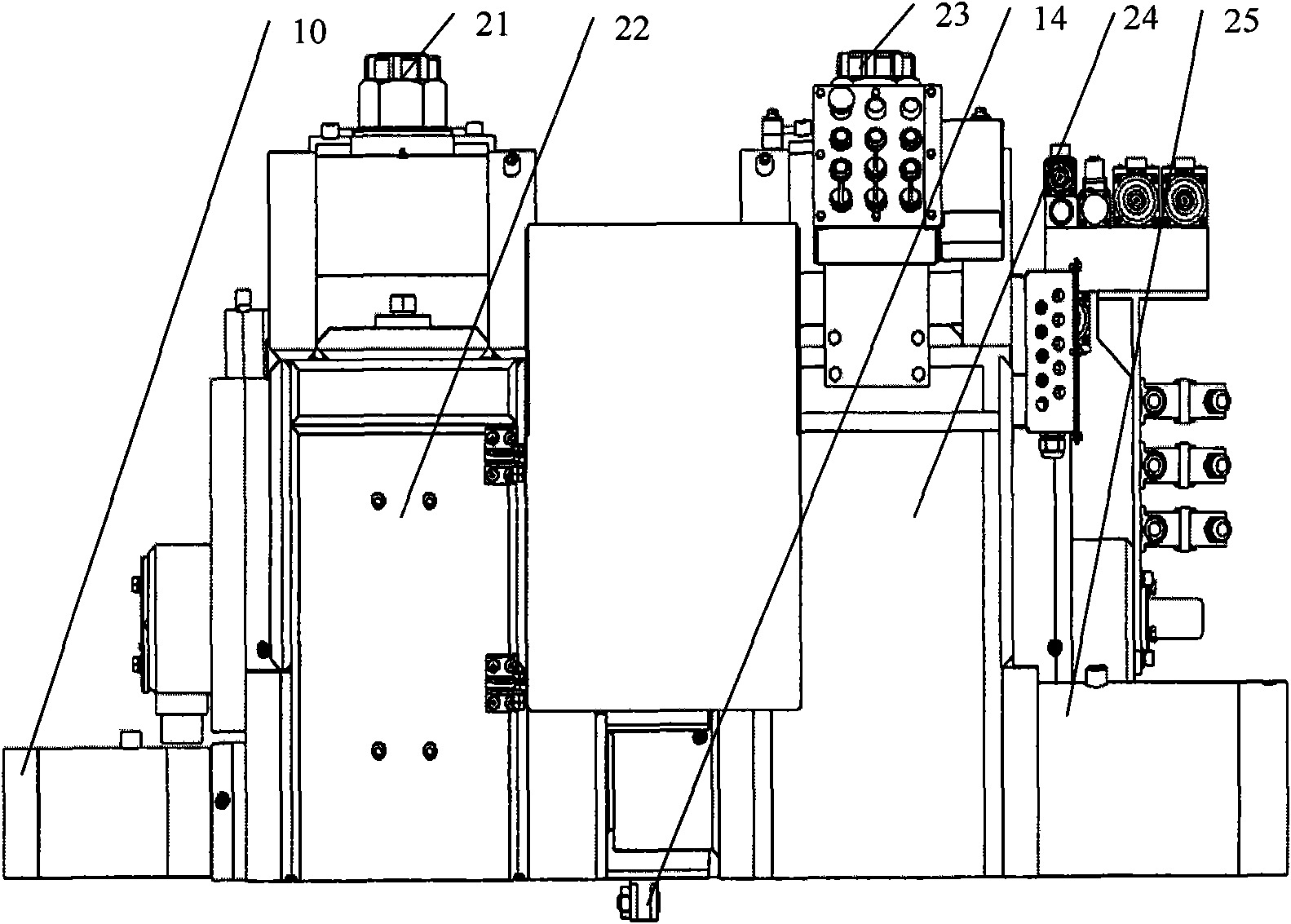

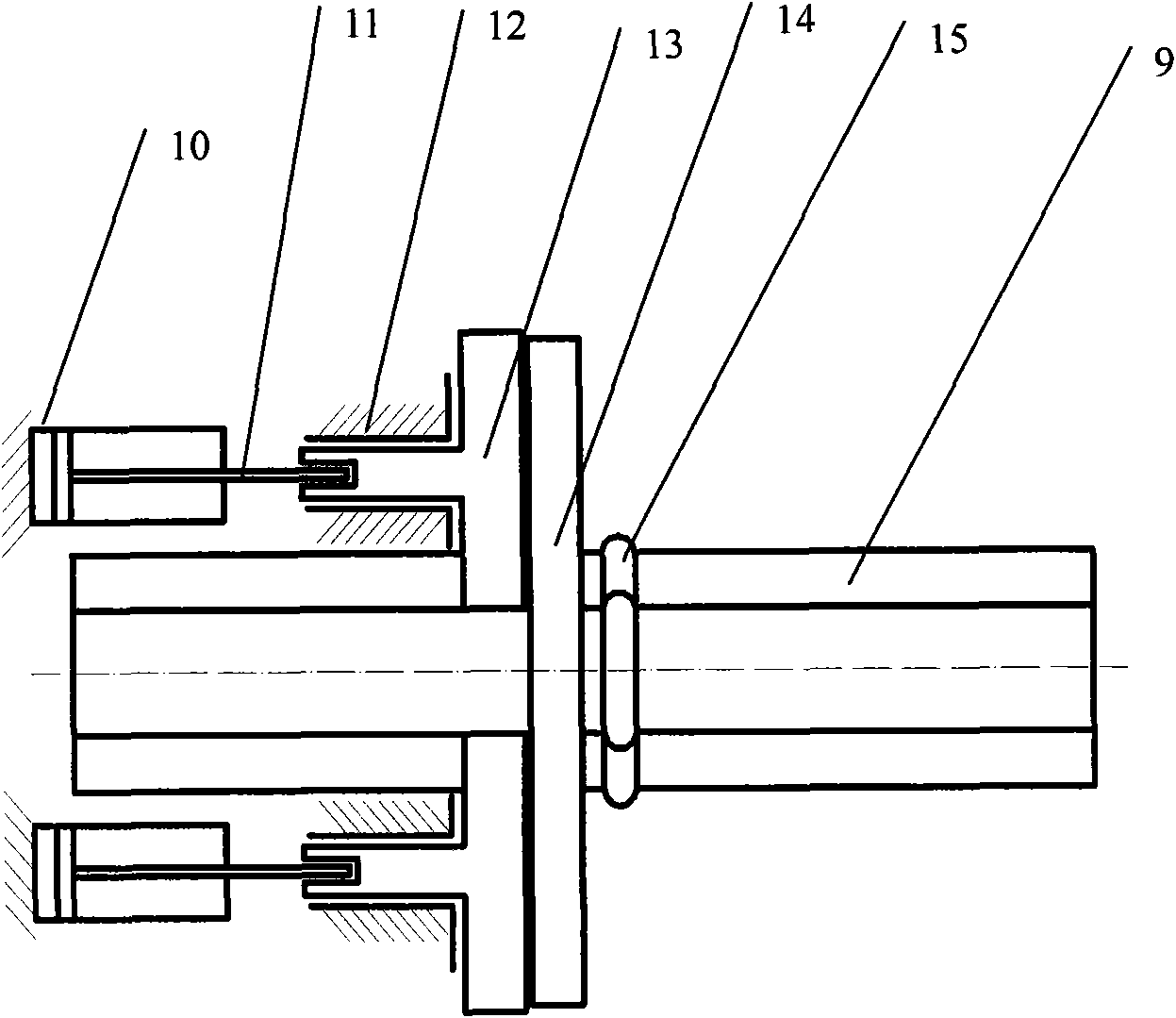

[0032] general reference figure 1 with 2 , shows a rail flash welder, which includes at least one fulcrum 101 mounted on the welder, at least two rail clamping mechanisms 100 mounted on the corresponding fulcrum, a flash welding transformer and at least At least one of the two rail clamping mechanisms makes the end of the clamped rail close to the upsetting actuation mechanism (here, the upsetting hydraulic cylinder 25). The at least two rail clamping mechanisms 100 may be mounted on a common fulcrum to facilitate alignment of the rails. Of course, these two rail clamping mechanisms can also be respectively installed on two different supporting shafts. The rail flash welder structure of the shown embodiment adopts a static rail clamping mechanism 24 and an axially movable movable rail clamping mechanism 22 . Alternatively, two moving rail clamping mechanisms that can approach each other can be used. Such as figure 2 As shown, before welding, the cylinders of the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com