Dyeing and finishing process of polyester-cotton cleaning conformal functional fabric

A functional and clean technology, applied in dyeing methods, fiber types, bleached products, etc., can solve the problems of low added value of products, easy contamination, and large resource consumption in dyeing and finishing processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

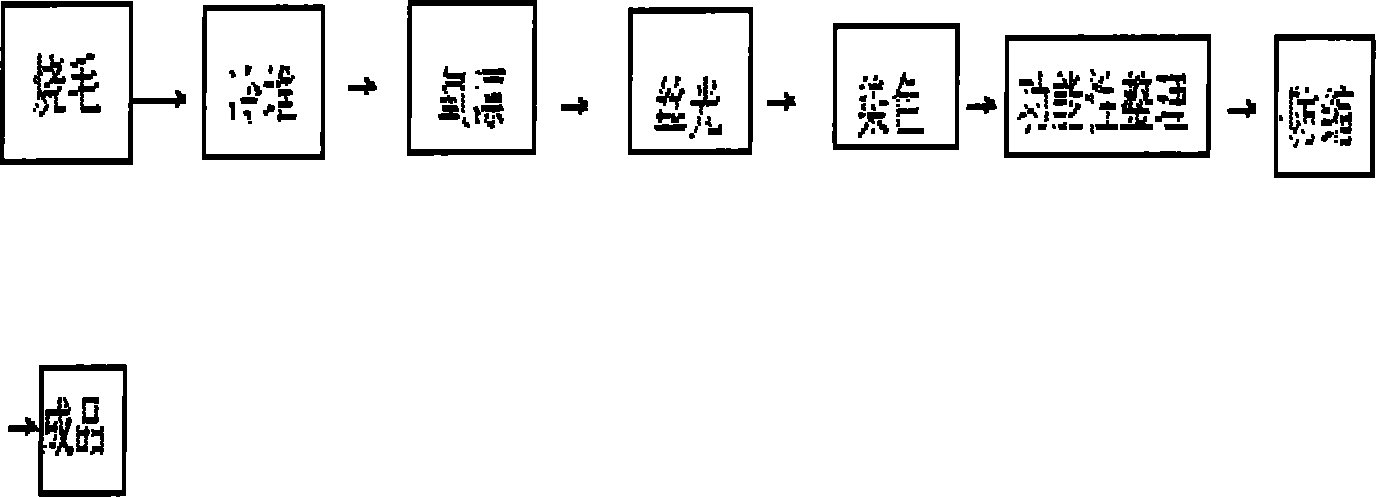

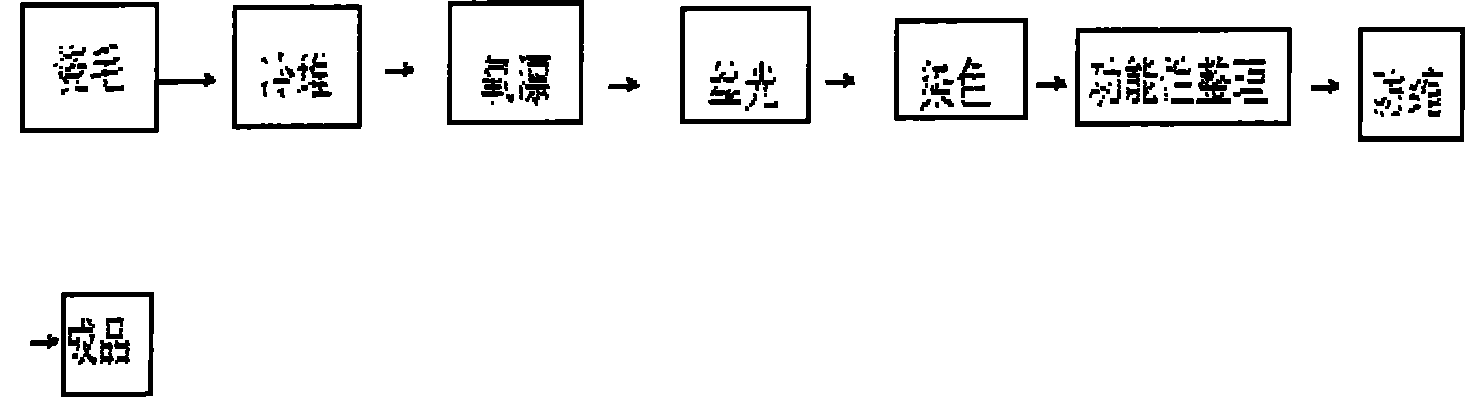

Image

Examples

Embodiment Construction

[0048] A dyeing and finishing process for polyester-cotton clean and shape-retaining functional fabrics. On the basis of the original characteristics of polyester and cotton, it has added good oil resistance, antifouling, easy decontamination and wrinkle resistance, and has the advantages of washing resistance and wear resistance. The specific processing steps are as follows:

[0049] (1) Preparation of raw materials Door width 140CM, warp and weft yarn count 40*40, warp and weft density 133*72, blending ratio: polyester-cotton blended fabric with 65% cotton and 35% polyester;

[0050] (2) singeing The prepared raw materials are subjected to singeing treatment,

[0051] Technological conditions: speed of 90-100m / min, flame temperature of 900℃~1100℃, four burners, equal number of singeing on both sides,

[0052] Process flow: turning cloth → sewing head → feeding cloth → bristles → 4 burners (2 positive and 2 negative) singeing → fire extinguishing → cooling → cloth dropping, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com