A high-performance flexible heat-resistant material and its technology

A heat-resistant material and high-performance technology, applied in textiles and papermaking, weft knitting, yarn, etc., can solve the problems that stainless steel fibers cannot meet the quality requirements of high-grade glass, cannot fully meet high-grade glass, and have a short service life. The effect of strength, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to make the present invention easier to understand, we will describe the present invention in more detail below in conjunction with the accompanying drawings and specific embodiments.

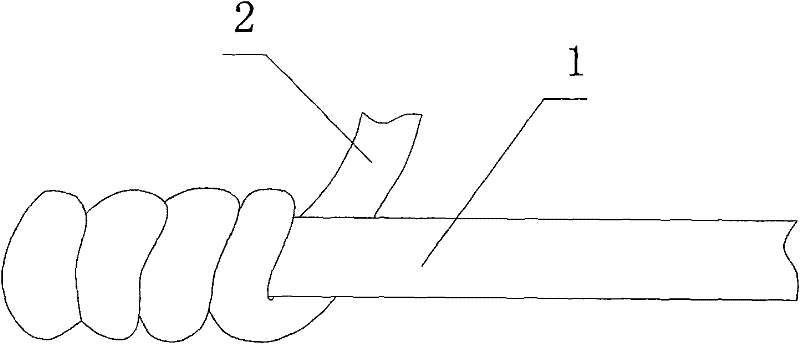

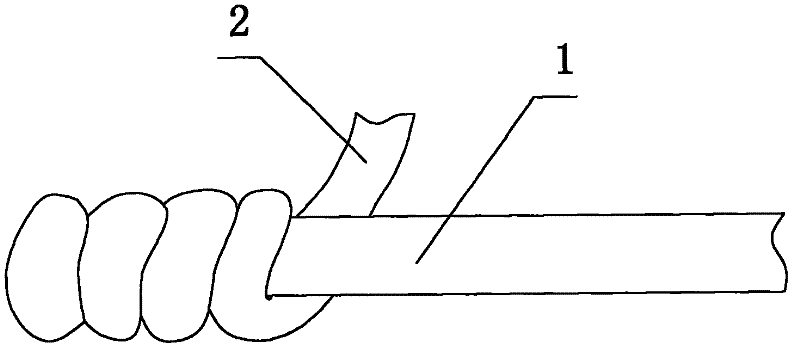

[0009] refer to figure 1 , a high-performance flexible heat-resistant material, which includes PBO staple fiber yarn 2 and stainless steel fiber yarn 1, wherein stainless steel fiber yarn has a count of 5 to 50 Nm and a diameter of 6 to 50 μm, and PBO staple fiber has a count of 5 ~60Ne, the content of PBO short fiber yarn 2 is 20%~80%, and the content of stainless steel fiber yarn 1 is 80%~20%. During preparation, the stainless steel fiber yarn 1 is first used as the core yarn, and the PBO staple fiber yarn 2 is wound on the stainless steel fiber yarn 1 in a spiral shape to form a covered yarn; then the covered yarn is twisted into two strands; finally, the strand is woven Knitted fabrics, finished products.

[0010] Take the PBO fiber yarn as 45Ne, the stainless steel fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com