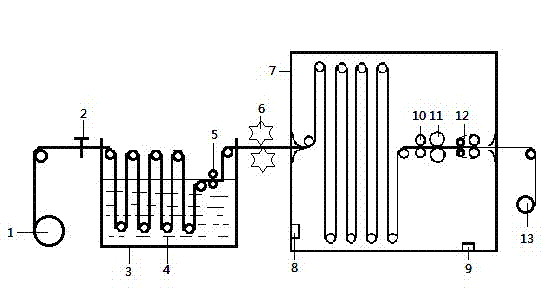

Fibrilia stretching and refining processor

A processing device and technology for hemp fibers, which are applied in the directions of liquid/gas/vapor fiber/sliver/roving treatment, solvent treatment, textile material treatment, etc. Fiber damage and other problems, to achieve the effect of improved flexibility, guaranteed potential loss, and less damage to hemp fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

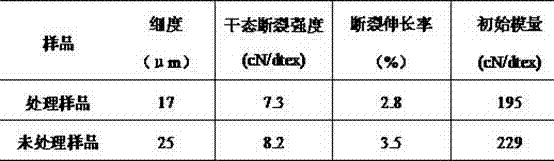

[0015] Example 1: Effect of jute process fiber treatment.

[0016] Treatment process: winding speed: 5 m / min; dispersing comb density: 30 teeth / cm; fiber liquid content rate after pressing water roller treatment: 10%; licker-in roller tooth density: 70 teeth / cm; in the stretching cabin : Steam temperature 110°C, relative humidity 90%. Stretch ratio: primary stretching: 1.4 stretching distance, the stretching distance is 1.2 times the average length of the hemp fiber bundle; secondary stretching: 1.8 stretching distance, the stretching distance is 1.7 times the average length of the hemp fiber bundle times. Referring to this process, the performance of the treated fiber was compared with that of the original fiber, and the results are shown in Table 1 below.

[0017] Table 1:

[0018]

[0019] It can be seen from the test that the stretched fiber has a large change in fineness, which has been reduced by nearly 30%. While the elongation at break of the fiber increases and...

Embodiment 2

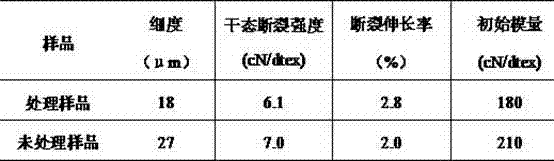

[0020] Embodiment 2: Hemp craft fiber treatment effect.

[0021] Treatment process: winding speed: 5 m / min; density of dispersing comb teeth: 40 teeth / cm; liquid content rate of fibers after pressing water roller treatment: 15%; tooth density of licker-in roller: 70 teeth / cm; : Steam temperature: 120°C, relative humidity 90%; Stretch ratio: primary stretching: 1.2 stretching gauge, stretching gauge is 1.2 times the average length of hemp fiber bundles; secondary stretching: 1.6 stretching gauge , The tensile gauge is 1.7 times the average length of the hemp fiber bundle. Referring to this process, the properties of the treated fibers were compared with those of the original fibers, and the results are shown in Table 2 below.

[0022] Table 2:

[0023]

[0024]It can be seen from the test that the stretched fiber has a large change in fineness. While the elongation at break of the fiber increases and the initial modulus decreases, the fiber exhibits better toughness and e...

Embodiment 3

[0025] Embodiment 3: Treatment effect of flax fiber.

[0026] Treatment process: Winding speed: 5 m / min; Dispersing comb: Teeth density: 30 teeth / cm; After water roller treatment, fiber liquid content rate: 15%; Licker-in roller tooth density: 80 teeth / cm; In the stretching cabin : steam temperature 130 ℃, relative humidity 95%; stretching ratio: primary stretching: 1.5 stretching gauge, stretching gauge is 1.3 times the average length of hemp fiber bundles; secondary stretching: 1.7 stretching gauge, The tensile gauge is 1.8 times the average length of the hemp fiber bundle. Referring to this process, the properties of the treated fibers were compared with those of the original fibers, and the results are shown in Table 3 below.

[0027] table 3:

[0028]

[0029] It can be seen from the test that the stretched fiber has a large change in fineness. While the elongation at break of the fiber increases and the initial modulus decreases, the fiber exhibits better toughness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com