Mine liquid-CO2 fire preventing and extinguishing process and device

A fire-preventing, liquid-state technology, applied in the direction of safety devices, fire prevention, dust prevention, etc., can solve the problems of pipeline leakage, increase the workload of enterprise pipeline maintenance, and the effect of cooling is not obvious, so as to achieve stable operation and anti-fire effect Remarkable and reliable, solve the effect of preventing gasification and freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

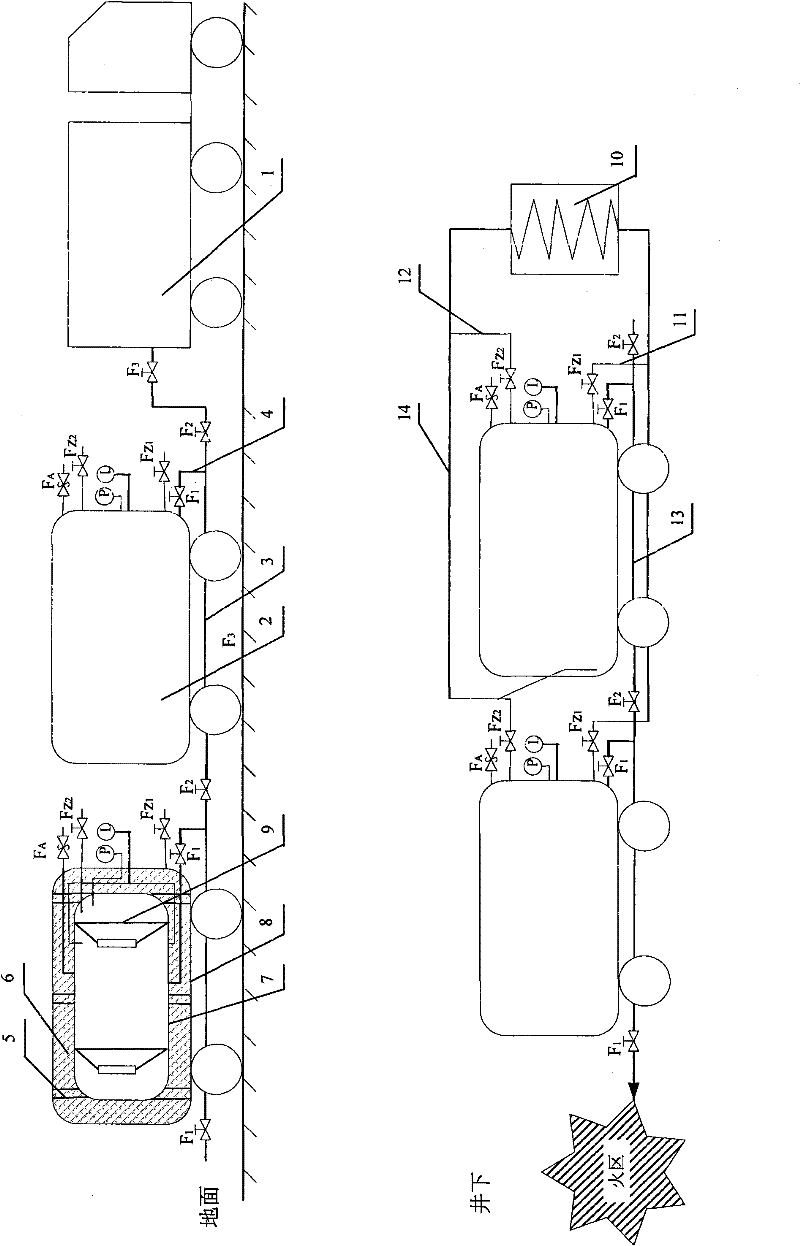

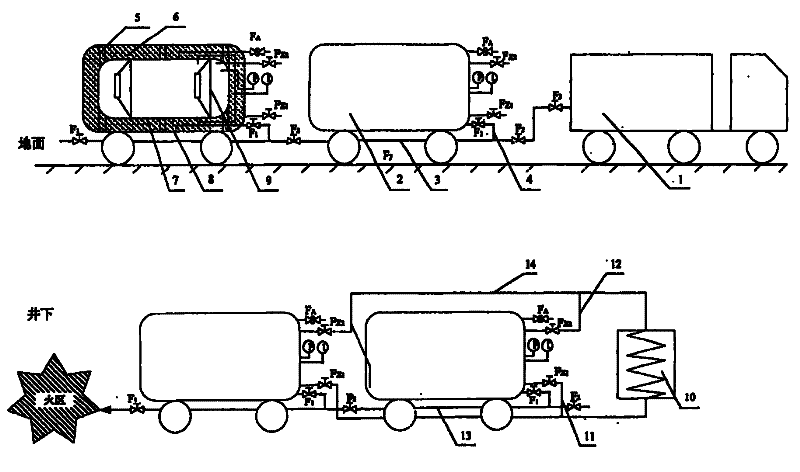

[0021] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0022] (1) Mine liquid CO of the present invention 2 The working principle and basic process of fire prevention and extinguishing technology

[0023] The working principle and basic process of the present invention are shown in the figure. Mine Liquid CO 2 The anti-fire extinguishing process is to put liquid CO 2 Transport to the underground fire area and fill the fire area with liquid, using liquid CO 2 Excellent anti-fire extinguishing performance to suffocate oxygen in the fire area, cool down and inert to suppress explosion, so as to achieve the purpose of anti-fire extinguishing. Liquid CO 2 The storage and transportation tanks are safely transported from the ground to the underground, avoiding freezing and blockage of the inlet and outlet main pipes during filling and CO 2 It is the key technology to inject into the fire zone in liquid state.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com