Infrared monitoring warner of abrasion of balance disc of multi-stage pump and infrared monitoring method thereof

An infrared monitoring, multi-stage pump technology, applied in the directions of alarms, instruments, pump control, etc., can solve problems such as hidden dangers of pump safety production, affecting enterprise production, missed judgment or wrong judgment, etc., to achieve simple structure, avoid missed judgment or Misjudgment, strong anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

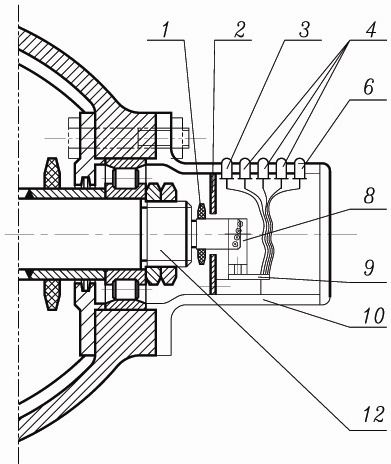

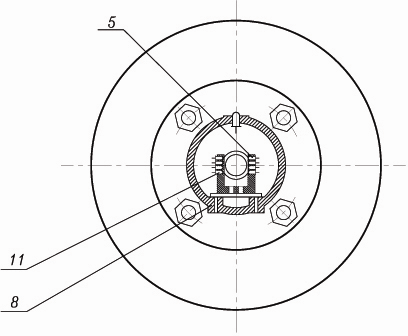

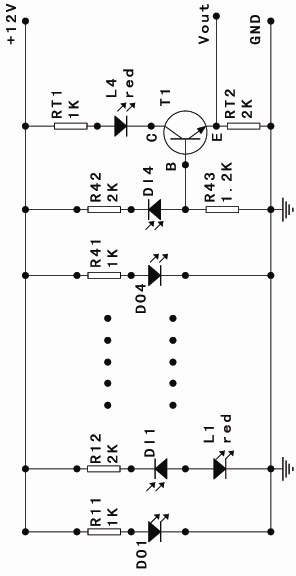

[0015] Such as Figure 1-Figure 3 As shown, an embodiment of the present invention includes a U-shaped support 8 located at the non-motor coupling end 12 of the main shaft of the multistage pump. One side of the U-shaped support 8 is sequentially provided with four infrared emission tubes 11. The U-shaped support 8 The other side is provided with four infrared receiving tubes 5 that match four infrared emitting tubes 11 one by one, and each matching infrared emitting tube 11 and infrared receiving tube 5 form a monitoring element, and correspond to the multistage pump main shaft A series of axial momentum. The four infrared emitting tubes 11 are connected to both ends of an input power supply in parallel, and the four infrared receiving tubes 5 are respectively electrically connected to a displacement signal lamp 4 and connected to both ends of the input power supply. For details, please refer to image 3 As shown in the schematic diagram of the circuit, in the figure: R11, R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com