A ball-end milling cutter with multifunctional micro-woven structure in titanium alloy machining

A multi-functional, titanium alloy technology, used in metal processing equipment, milling cutters, milling machine equipment, etc., can solve problems such as wire winding, achieve timely lubrication, environmentally friendly lubrication, and prevent excessive chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

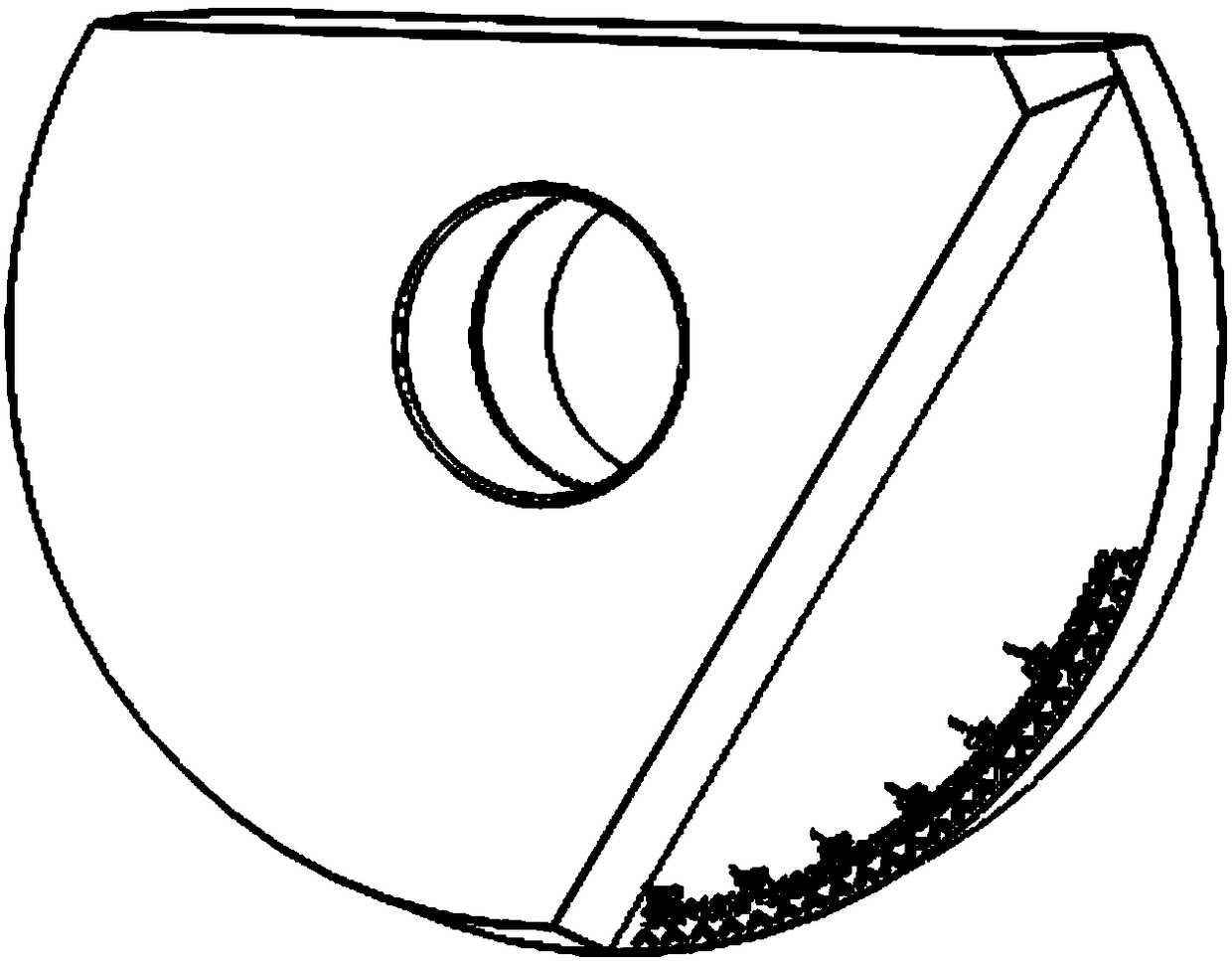

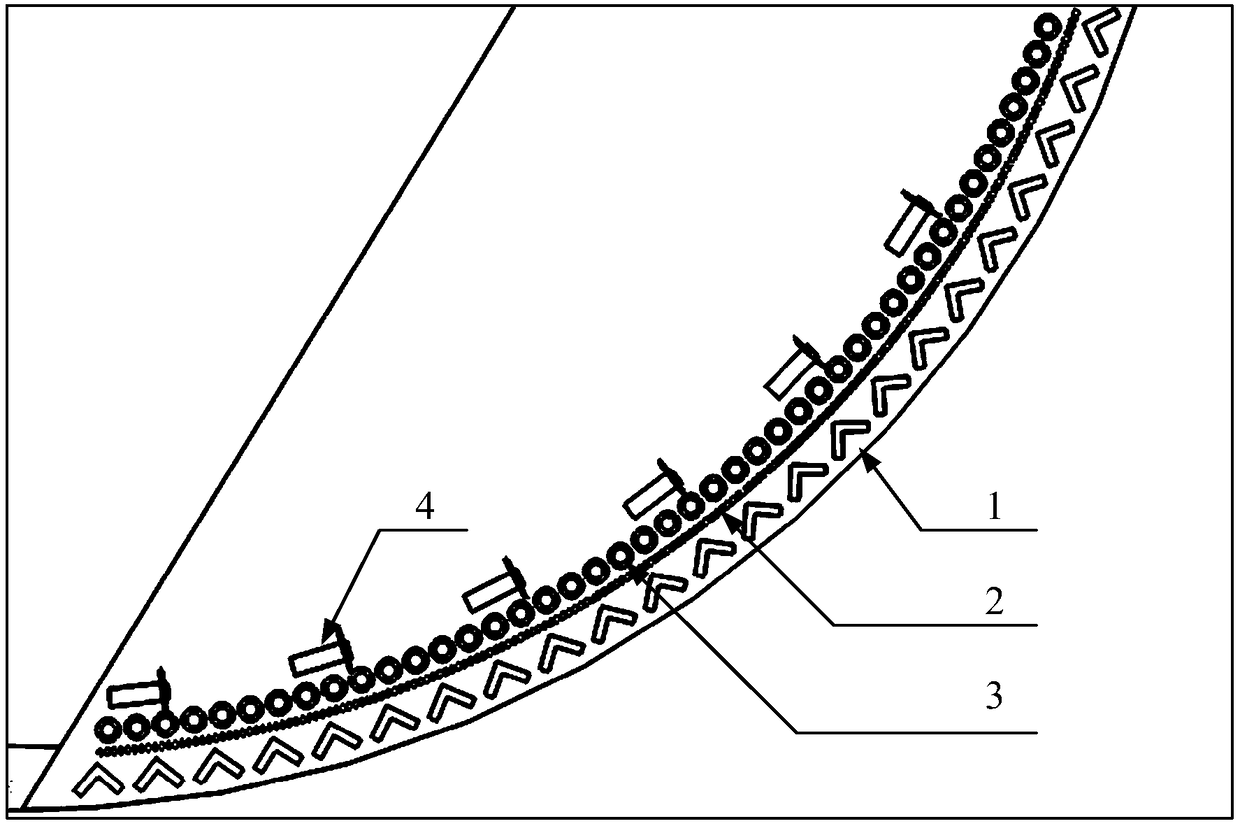

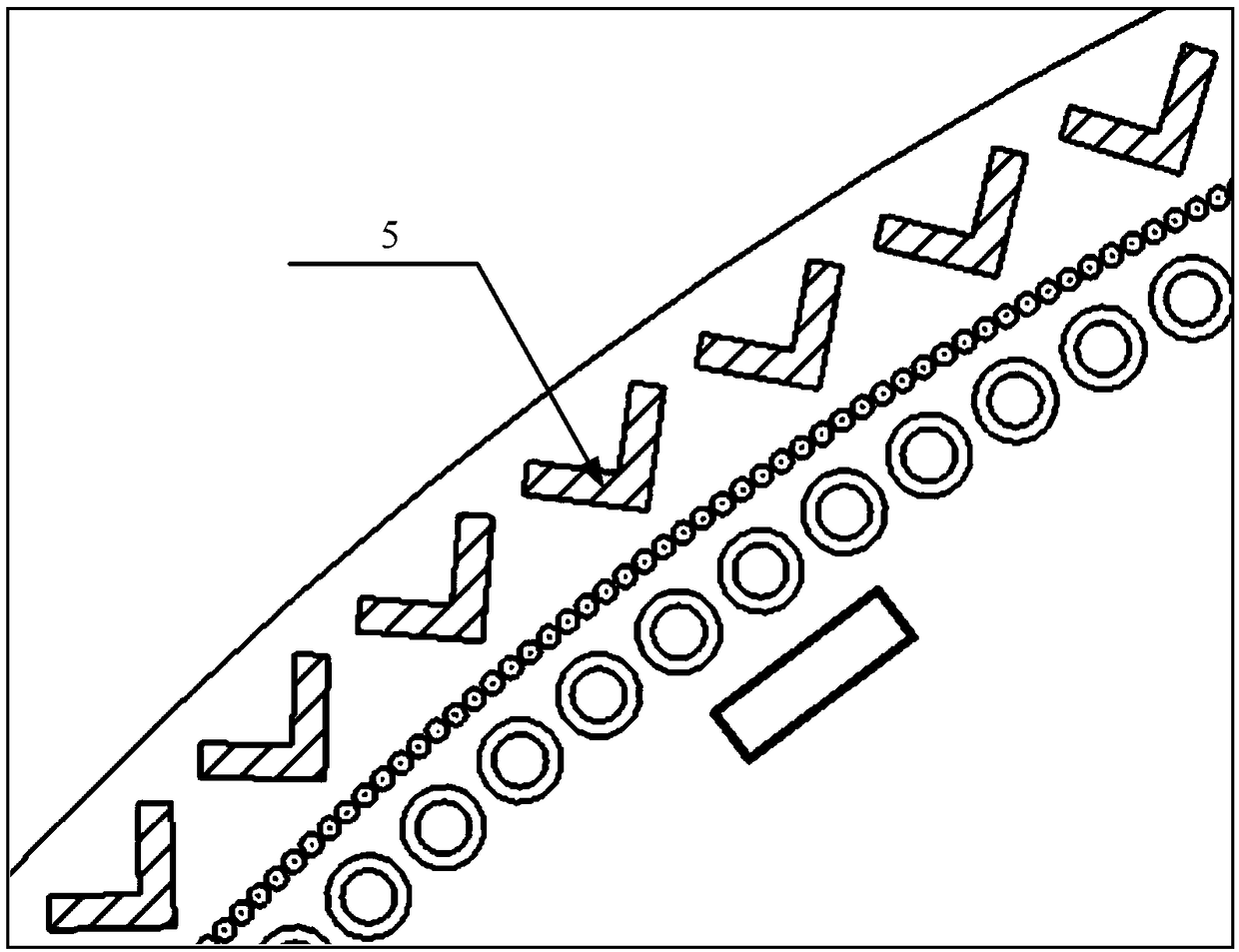

[0008] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, a ball end milling cutter with a multi-functional micro-weave structure in titanium alloy processing described in this embodiment, it includes a cutter head, the blade of the cutter head is provided with at least one Arrow-shaped micro-weave structure 1 , at least one zigzag-shaped micro-weave structure 2 , at least one bowl-shaped micro-weave structure 3 , and at least one rectangular micro-weave structure 4 . Each micro-weave structure has a certain order. The arrow-shaped micro-weave structure 1 is closest to the blade, followed by the zigzag micro-weave structure 2, the bowl-shaped micro-weave structure 3 and the rectangular micro-weave structure 4. The advantage of this arrangement is that the blade Allows quick access and full access to the tool-chip contact area. After the zigzag micro-woven structure 2 breaks the chip, it is quickly discharged by the bowl-shaped micro-wove...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 1 to Figure 6 To illustrate this embodiment, the arrow-shaped micro-weave structure 1 of a ball-end milling cutter with a multi-functional micro-weave structure in this embodiment is arranged along the arc direction of the cutting edge, and the arrow-shaped The microtexture structure 1 has a width of 80 μm, a texture depth of 100 μm, and a length of 300 μm. The included arrow texture angle of the arrow-shaped micro-texture structure 1 is 90°, and the texture can be completed by femtosecond laser processing technology, chemical etching or 3D printing technology. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 1 to Figure 6 This embodiment is described. The zigzag micro-weave structure 2 of a ball end milling cutter with a multi-functional micro-weave structure in the processing of titanium alloy described in this embodiment is arranged along the arc direction of the cutting edge, and the zigzag shape Microtexture 2 is a convex texture body with a tooth height of 50 μm and a draft angle of 25°. The texture adopts the electrodeposition preparation method of metal chromium coating, and the metal chromium coating has strong wear resistance; after pretreatment on the surface of the tool, the material is entered into the acid electrolyte for electric sinking, and heat treatment is carried out after coating, so as to obtain Convex micro-texture structure, this texture plays a role in breaking chips in titanium alloy processing, which is conducive to the timely discharge of chips. Other components and connections are the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com