Automatic integrated device for mining, discharging, monitoring and supporting model test

A model test, automatic technology, applied in soil material testing, material inspection products, etc., can solve problems such as insufficient accuracy, large stress-displacement distribution error, secondary damage to the excavation surface, etc., to improve automation and intelligence, expand Scope of application, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention will be described below in conjunction with the accompanying drawings.

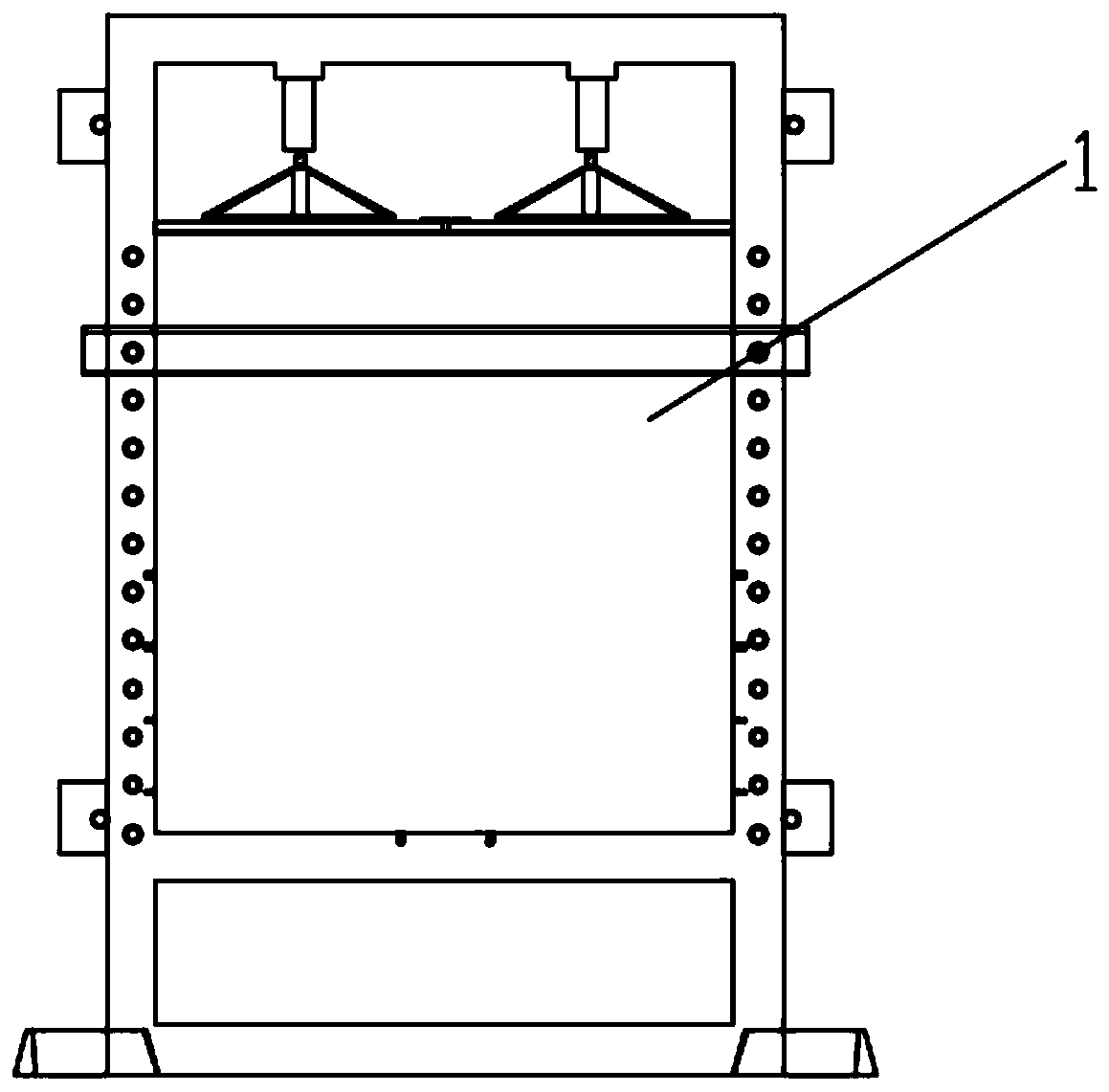

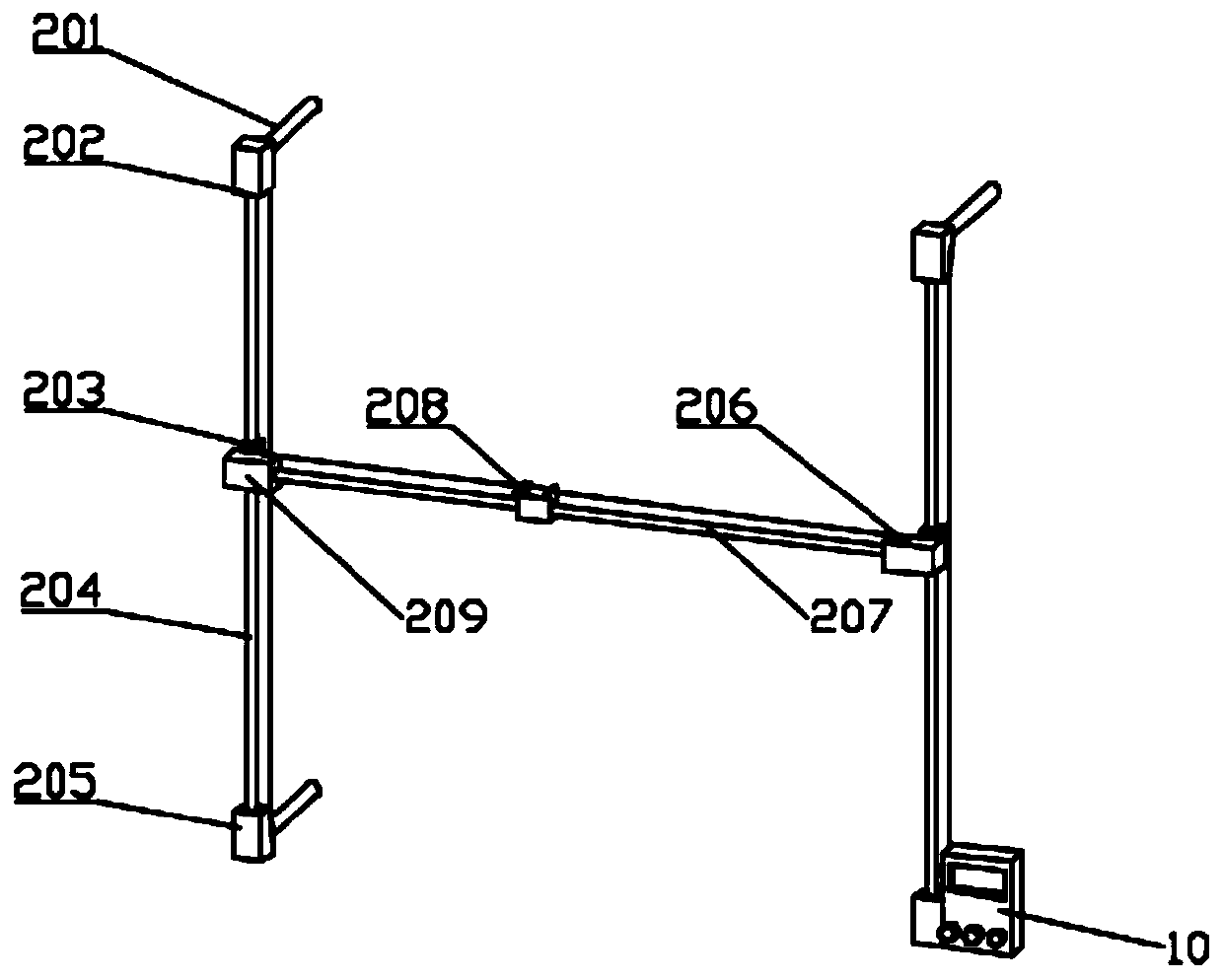

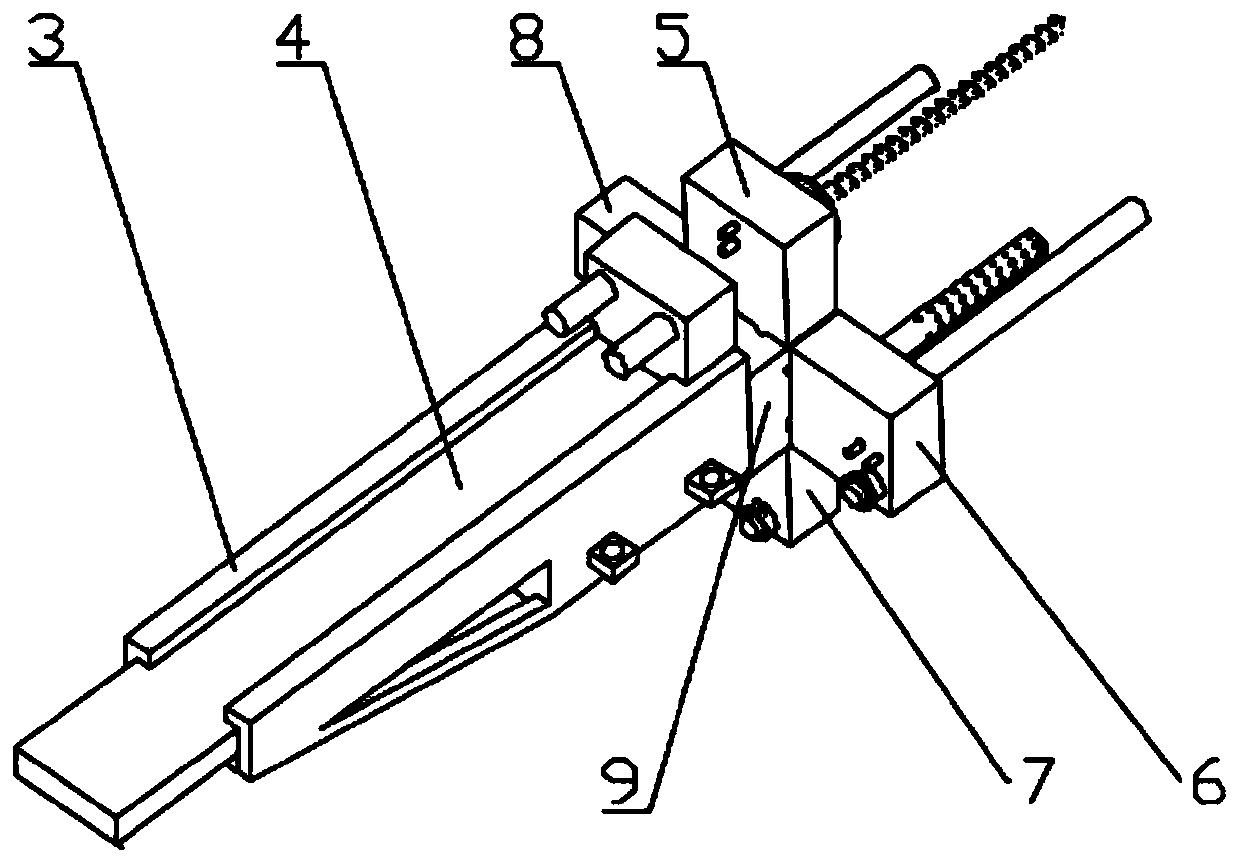

[0030] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, a kind of automatic integrated device for mining, rowing, monitoring and protecting for model tests is characterized in that it includes a motion guide rail device 2, a multifunctional integrated device The base 3, the sliding guide rail 4 of the multifunctional integrated device, the drilling module 5, the chip removal module 6, the support module 7, the monitoring module 8, the rotating body 9, and the control device 10; 201 is fixedly connected with the model mechanical test device 1; the base 3 of the multifunctional integrated device is fixedly connected with the horizontal slider 207 on the moving guide rail device 2 through the bolt I, and the motor III 302 and the motor IV 303 are respectively fixed on the In the base 3 of the multifunctional integrated device, the motor IV 303 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com