A vertical punching device for industrial boards that is convenient for chip removal

A technology of punching device and plate, applied in the direction of manufacturing tools, fixed drilling machines, wood processing appliances, etc., can solve the problems of easy damage of drill bits, inability to discharge wood chips, damage, etc., to prevent wood chips from splashing, facilitate centralized processing, and facilitate The effect of timely chip removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

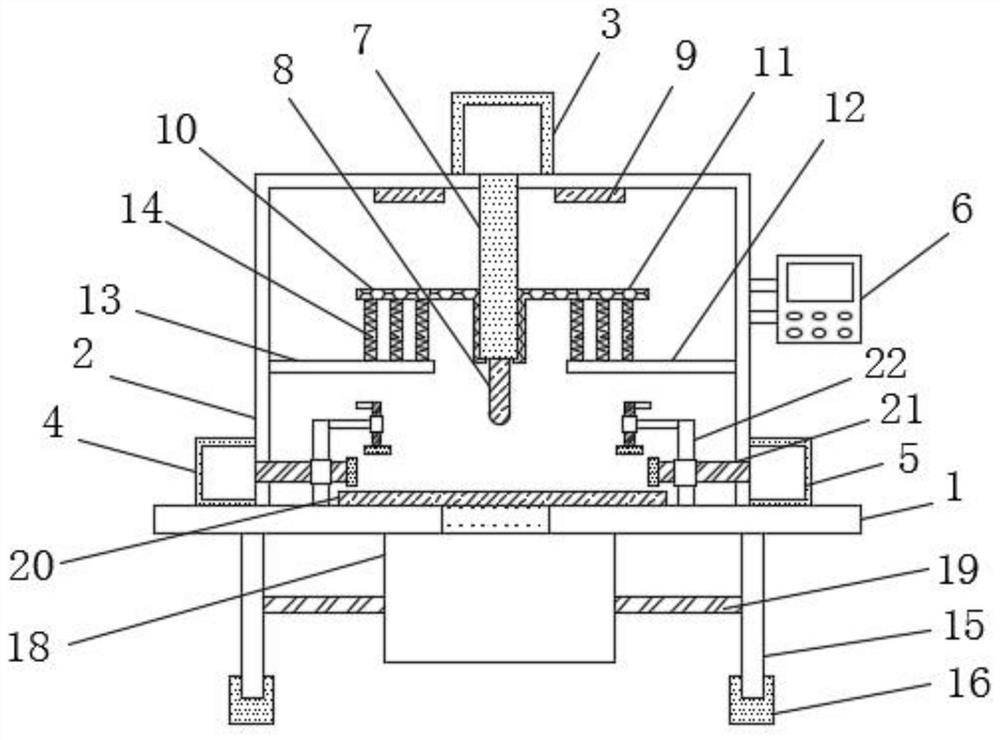

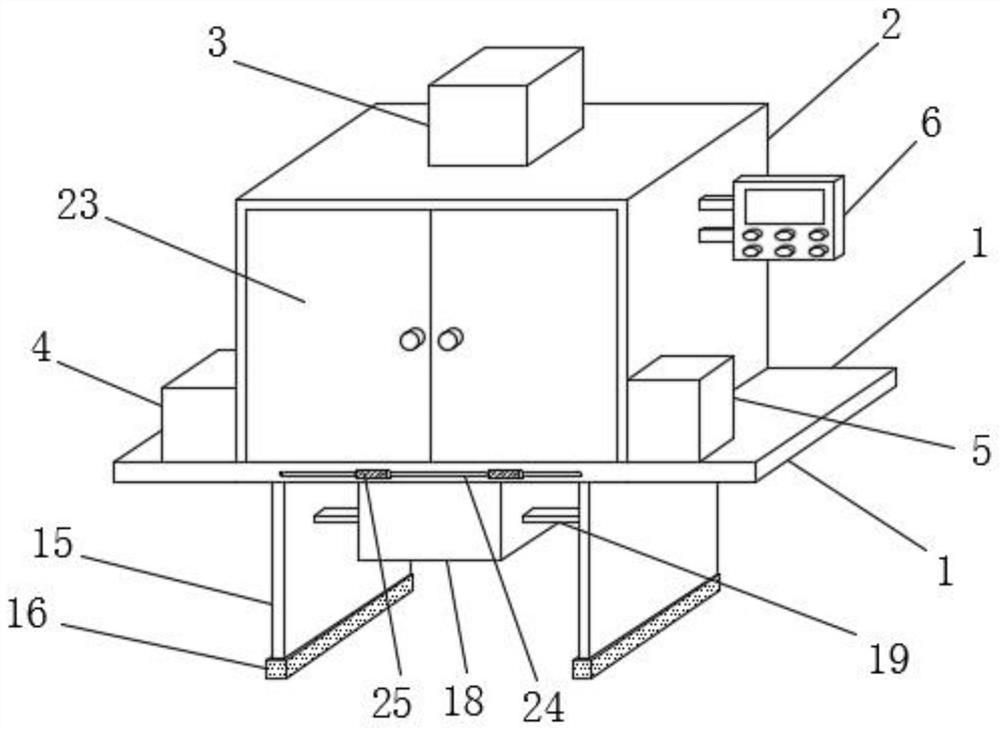

[0040] see Figure 1-2 As shown, a vertical punching device for industrial boards that is convenient for chip removal includes a workbench 1, and a device shell 2 is fixedly installed on the upper outer surface of the workbench 1, and the middle position of the upper end outer surface of the device shell 2 is A No. 1 cylinder 3 is installed, and the two sides of the device shell 2 are respectively installed with a No. 2 cylinder 4 and a No. 3 cylinder 5 near the bottom end. A control panel 6 is fixedly installed above the No. 3 cylinder 5. There is a No. 1 hydraulic telescopic rod 7 installed on the bottom surface of the cylinder 3 and located in the middle of the upper end of the device housing 2. The bottom end of the No. 1 hydraulic telescopic rod 7 is equipped with a drill bit 8, and the No. 1 hydraulic telescopic rod 7 is close to the upper end. Limiting baffles 9 are installed on both sides, and a No. 1 spring plate 10 and a No. 2 spring plate 11 are respectively install...

Embodiment 2

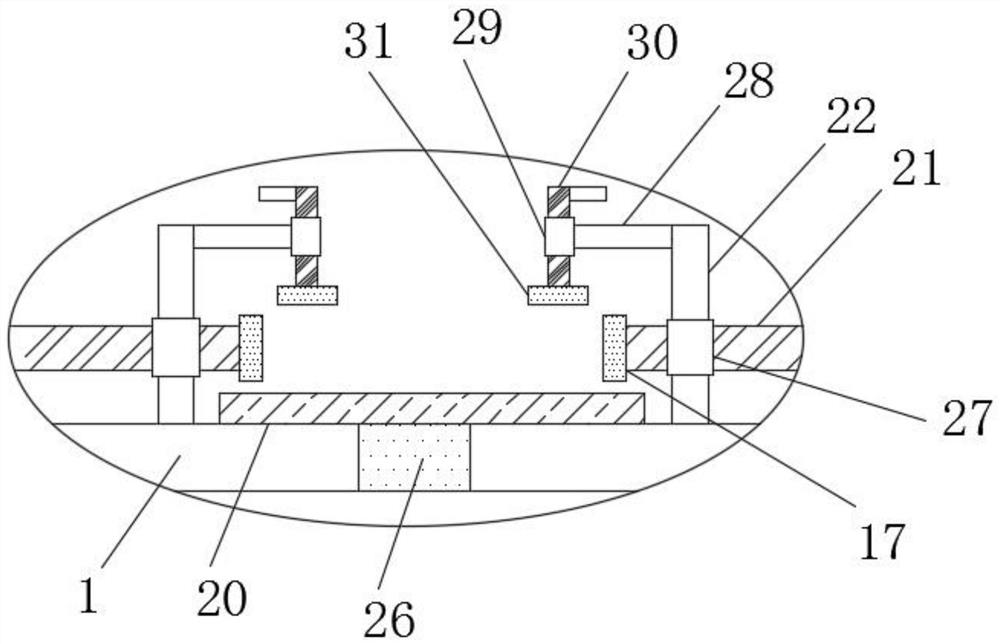

[0043] see Figure 3-4 As shown, the other end of the No. 2 hydraulic telescopic rod 21 is equipped with a transverse limit pad 17, and a sawdust outlet 26 is opened through the inner middle position of the workbench 1. The No. 2 hydraulic telescopic rod 21 and the column 22 A protective cover 27 is installed at the connection position of the vertical column 22, and a cross bar 28 is connected to the upper end of the column 22. An annular frame 29 is installed on the end of the horizontal bar 28 away from the column 22, and an adjusting bolt is slidably installed on the inner wall of the annular frame 29. 30, the bottom end of the adjustment bolt 30 is installed with a vertical limit block 31;

[0044] A fixed block 32 is fixedly installed in the middle position of the No. 1 hydraulic telescopic rod 7, and a light spring 33 is connected between the fixed block 32 and the top of the drill bit 8;

Embodiment 3

[0046] see Figure 5-8 As shown, the middle position of the upper outer surface of the buffer pad 20 is provided with a No. 2 slideway 34, and two sets of vertical slide bars 35 are installed in parallel sliding inside of the No. 2 slideway 34. The buffer pad 20 Slide rails 36 are provided on both sides of the inside of the slide rail 36, and the No. 1 slide plate 37 and the No. 2 slide plate 42 are slidably installed on the slide rail 36. The middle position of the No. 1 slide plate 37 and the No. 2 slide plate 42 is provided with a joint block 38, a chute 39 is opened on the inner side of the workbench 1, and two sets of horizontal sliding bars 40 are slidably installed in the chute 39, and the connecting block 38 is connected with the bottom end of the vertical sliding bar 35 A fixing bolt 41 is installed.

[0047] Preferably, the vertical slide bar 35 is vertically arranged and fixedly connected to the horizontal slide bar 40, and the vertical slide bar 35 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com