An online control system and control method for lubricating oil in a wind turbine gearbox

A wind turbine and control system technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, mechanical equipment, etc., can solve the unreliable replacement of filter elements and lubricating oil, affect the lubrication effect, increase the wear and tear of gears and bearings Risk and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

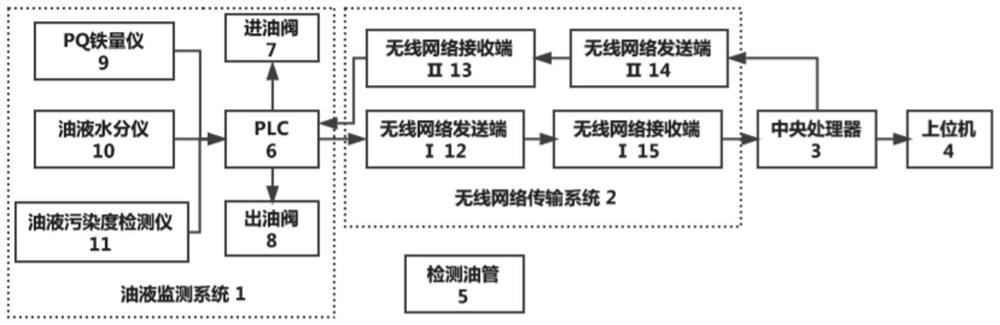

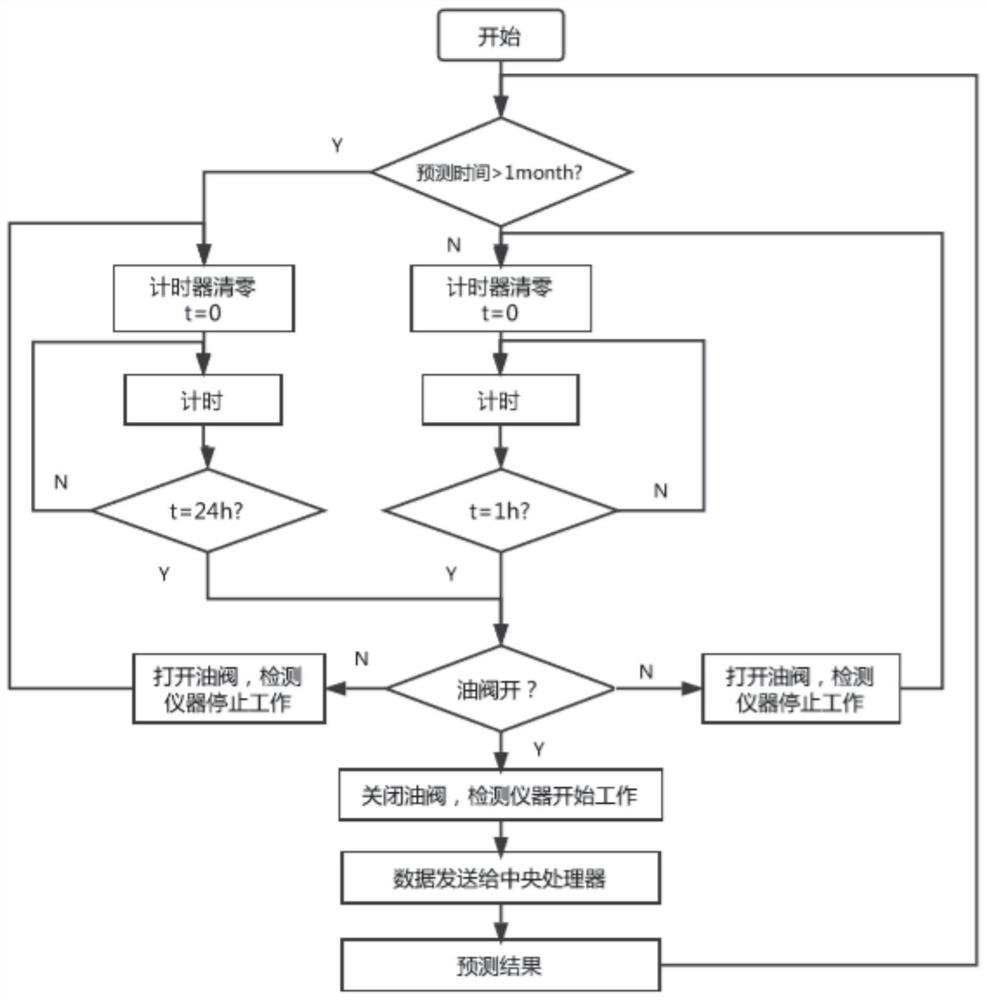

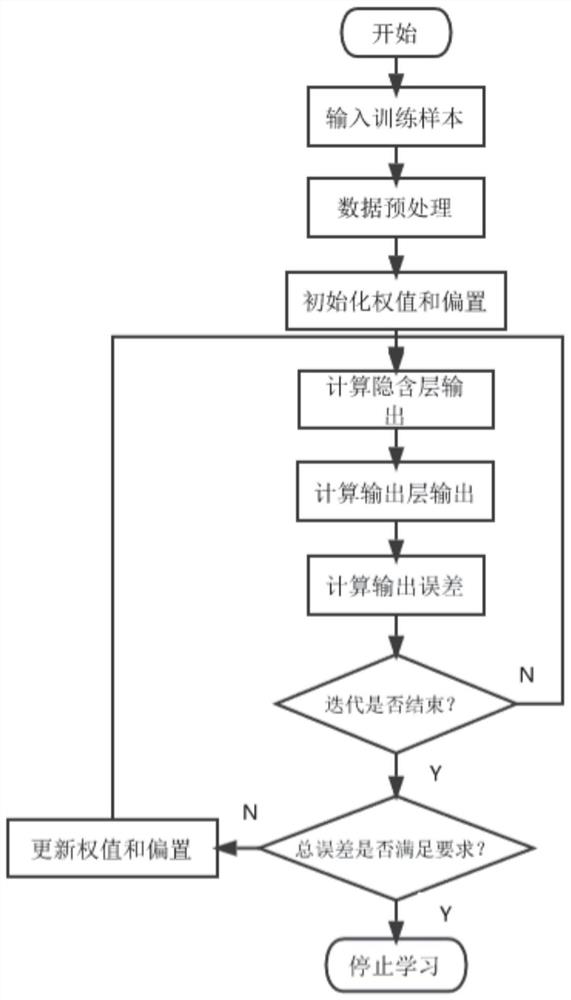

[0025] Embodiment 1: as Figure 1-4 As shown, an online control system for lubricating oil in a wind turbine gearbox includes an oil monitoring system 1, a wireless network transmission system 2, a central processing unit 3, a host computer 4, and a detection oil pipe 5, wherein the oil monitoring system 1 Including PLC6, oil inlet valve 7, oil outlet valve 8, PQ iron gauge 9, oil moisture meter 10, oil pollution degree detector 11; wireless network transmission system 2 includes wireless network sending terminal I 12, wireless network receiving terminal II 13, wireless network sending terminal II 14, wireless network receiving terminal I 15;

[0026]The oil inlet valve 7 and the oil outlet valve 8 are respectively installed at the oil inlet end and the oil outlet end of the detection oil pipe 5, and the PQ iron meter 9, the oil moisture meter 10, and the oil pollution degree detector 11 are all installed at the inlet On the detection oil pipe 5 between the oil valve 7 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com